Dyeing PBT caps with Dylon: some experiments

Posted: 29 Feb 2012, 22:16

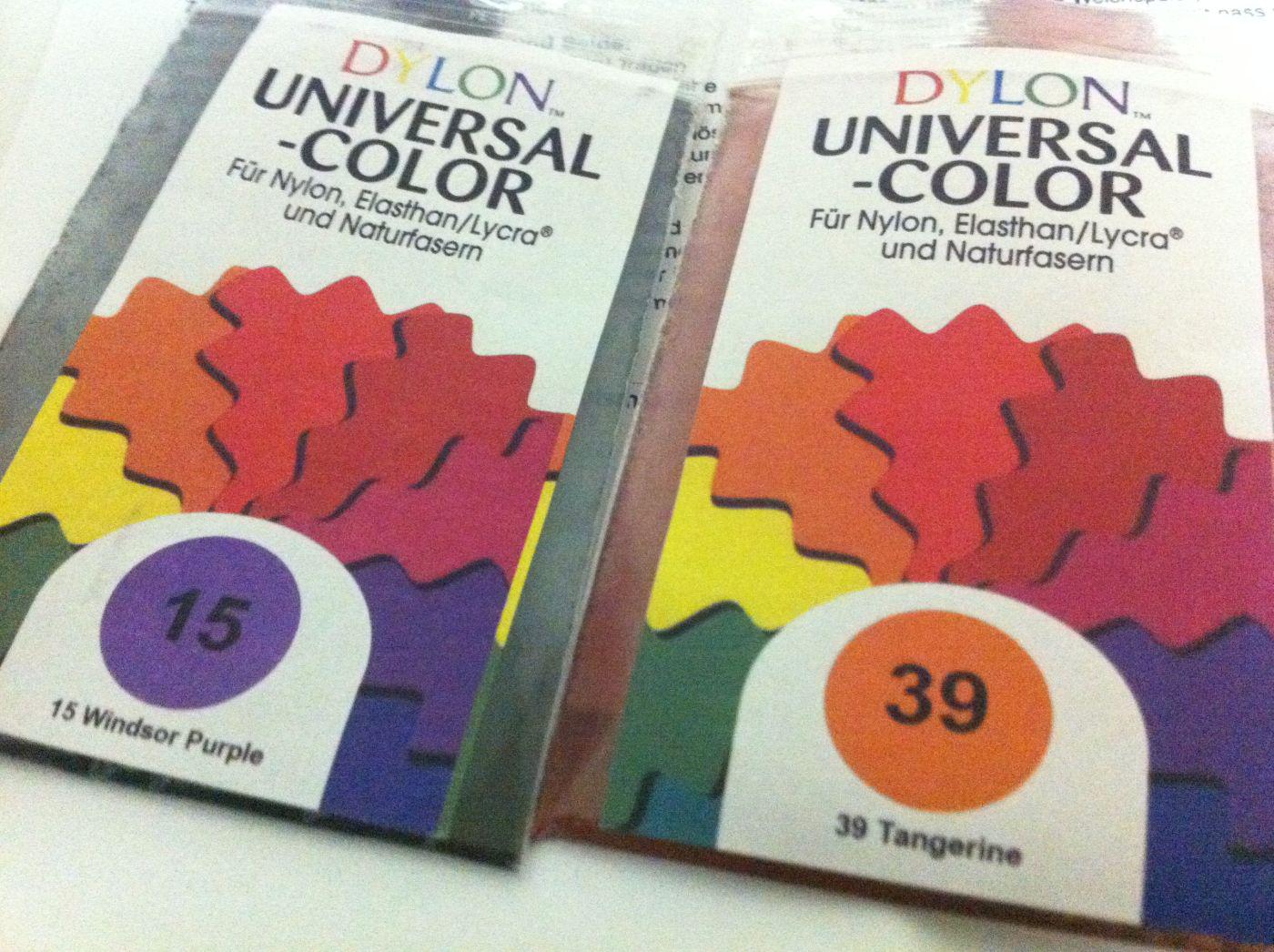

With all that Rit-dyeing going on and no easy source for that stuff in Europe I went to look for alternatives. Dylon universal dye or multi-purpose dye as it is also called, seemed to be ok for key caps as it is suitable for dyeing nylon, lycra and buttons. And it's generally available where I live (The Netherlands) but also in the UK and Germany and probably in more countries.

It comes in various package sizes and I found a few mini tins of 4.5 g each at a local craftshop.

A set of PBT caps (nearly-white and light grey) of a Cherry MY board (G81-3504LAAEU) was picked as victim along with a few caps of an IBM model M.

I found an old aluminum camping pan to perform this experiment in. Note: aluminium pans are not the best choice, see conclusions & recommendations.

The general procedure was as follows:

*The dye (4.5 g) was dissolved in 700 mL of boiling tap water

*The heat source was removed and 30 g of table salt was added whilst stirring until completely dissolved

*The pan was put on a simmering plate and the keycaps were added

*The mixture was gently stirred for the indicated time while the temperature was kept between 60 - 80 °C (estimated)

*After the dyeing process, the caps were washed with warm tap water and soap

1st round:

Dylon No 25: Emerald

An oily film appeared on the surface of the dyeing mixture. Probably some traces of instant-noodles. I should've cleaned the pan more thoroughly Some of the film stuck to the caps causing some uneven coloring. In the end (after 30-35 min) the key caps came out OK but the space bar clearly shows some darker regions.

Some of the film stuck to the caps causing some uneven coloring. In the end (after 30-35 min) the key caps came out OK but the space bar clearly shows some darker regions.

The result is caps with quite a light green color on the near-white caps and a forest, almost military green on the grey caps. Scroll down for pictures of the result.

2nd round:

Dylon No 19: Deep Blue

The pan was thoroughly cleaned with an oven cleaning agent ("Muscle" brand) and some iPrOH. The caps were rinsed with iPrOH. No oily skin on the mixture this time.

Blue surprised me: The caps nearly went otaku within 10 min, that's how well they absorbed the dye. The near-white and the light grey caps came out looking nearly the same.

3rd round:

Dylon No 10: Cherry Flame (couldn't resist)

Pan cleaned with oven-cleaner, this stuff also removed dye residues. Caps rinsed with iPrOH.

This dye bath became a bit flaky over time but the dyeing process went really well. After 40 min of simmering I had some nice, red caps. They darkened a bit on drying.

4th round:

Dylon No 2: Golden Glow

Again in a clean pan with clean caps: As an experiment, the salt was added after the key caps in two equal portions. On adding the salt, some of the dye precipitated (that's probably one of the functions of the salt).

Something went wrong in this run. The caps immediately got some specks of concentrated dye on them; those did not fade during 50 min of simmering. Could be due to the late addition of salt but I really suspect that the dye wasn't completely dissolved before I threw in the caps.

Afterwards, the caps darkened a bit on drying, and now they look more gold-brown than yellow, especially the ones that were grey before. Well, the dye is called golden glow after all. These are the only dyed caps that I'm unhappy with mainly due to the ugly specks and stains.

Results:

Look at all these funky colors on top of some squishy MY switches! and those 4 model M caps! I'm rather pleased in general, only the failed yellows are a pity.

Here's the most important picture, a key matrix Some problem zones: The dye is rather sensitive for irregularities in the plastic. The injection points of the caps take up the dye worse than other parts. One of the IBM caps has some smears of lighter color on it. I don't know if this is caused by the plastic structure or if this cap was a bit dirty.

Some problem zones: The dye is rather sensitive for irregularities in the plastic. The injection points of the caps take up the dye worse than other parts. One of the IBM caps has some smears of lighter color on it. I don't know if this is caused by the plastic structure or if this cap was a bit dirty.

The sides of the IBM caps were sligthly warped but they still fit very well on their stems. Only tighter than before.

Conclusions & recommendations:

*Dyeing PBT caps with Dylon universal / multi-purpose dye works.

*The color doesn't rub off. No blue fingers so far.

*The Cherry caps keep their shape while the IBM M caps are slightly bent inwards. Don't be alarmed, they still fit on their stems very well.

*Some dyes obviously are absorbed better than others.

*Clean and degrease your pan! And your caps!!

*Dissolve the dye completely before adding the caps.

*Aluminium pans are generally a bad choice as this metal corrodes in acid or basic aqueous solutions.

*Quite some dye stuck to my pan due to its rough surface which made cleaning very difficult. I suggest using a smooth stainless steel pan or even better an enamel pan or a large glass beaker.

*I'm still not sure if the salt is necessary for dyeing key caps but it won't hurt to add it. BTW, it is absolutely necessary when dyeing textiles.

Future plans:

*The dye solutions were a bit heterogeneous. Next time I will try a larger volume (1 L water) and less salt (10 g). I'll also experiment with acetic acid as mordant instead of salt. All that will be done in a non-aluminum pan.

*I need to get a thermometer...

*Dylon multi-purpose dye, just as Rit dye, is a mixture of components: It consists of a reactive dye for cotton and rayon (probably useless for key caps), further an "acid dye" component for nylon and wool and possibly also a dispersion dye. I think it's the latter two that do the trick for the caps. It could be worthwhile to look for a source of pure acid dyes or disperse dyes that are designed for polyesters. Technically spoken, PBT is a polyester but it's rather different from the most common polyester, PET (polyethylene terephthalate) PET is the raw material for polyester textiles like your fleece sweater but also for soft drink bottles. My guess is that you can color PBT with dyes that are not able to penetrate PET.

Sources & links:

*Dylon multi-purpose dye (Dutch site): http://www.dylon.nl/products/verven/multi-purpose-tins/

*Dylon (English site, only shows the large 500 g tins): http://www.dylon.co.uk/product.php?alia ... e-dye-500g

*A great site about dyeing, lots of information: http://www.pburch.net/dyeing.shtml

*About Rit and Dylon multi-purpos dyes: http://uk.answers.yahoo.com/question/in ... 016AAkeooD

*Geekhack example of dyeing Model M caps with Rit: http://geekhack.org/showwiki.php?title=Island:15277

edit: removed some macabre typos

It comes in various package sizes and I found a few mini tins of 4.5 g each at a local craftshop.

A set of PBT caps (nearly-white and light grey) of a Cherry MY board (G81-3504LAAEU) was picked as victim along with a few caps of an IBM model M.

I found an old aluminum camping pan to perform this experiment in. Note: aluminium pans are not the best choice, see conclusions & recommendations.

The general procedure was as follows:

*The dye (4.5 g) was dissolved in 700 mL of boiling tap water

*The heat source was removed and 30 g of table salt was added whilst stirring until completely dissolved

*The pan was put on a simmering plate and the keycaps were added

*The mixture was gently stirred for the indicated time while the temperature was kept between 60 - 80 °C (estimated)

*After the dyeing process, the caps were washed with warm tap water and soap

1st round:

Dylon No 25: Emerald

An oily film appeared on the surface of the dyeing mixture. Probably some traces of instant-noodles. I should've cleaned the pan more thoroughly

The result is caps with quite a light green color on the near-white caps and a forest, almost military green on the grey caps. Scroll down for pictures of the result.

2nd round:

Dylon No 19: Deep Blue

The pan was thoroughly cleaned with an oven cleaning agent ("Muscle" brand) and some iPrOH. The caps were rinsed with iPrOH. No oily skin on the mixture this time.

Blue surprised me: The caps nearly went otaku within 10 min, that's how well they absorbed the dye. The near-white and the light grey caps came out looking nearly the same.

3rd round:

Dylon No 10: Cherry Flame (couldn't resist)

Pan cleaned with oven-cleaner, this stuff also removed dye residues. Caps rinsed with iPrOH.

This dye bath became a bit flaky over time but the dyeing process went really well. After 40 min of simmering I had some nice, red caps. They darkened a bit on drying.

4th round:

Dylon No 2: Golden Glow

Again in a clean pan with clean caps: As an experiment, the salt was added after the key caps in two equal portions. On adding the salt, some of the dye precipitated (that's probably one of the functions of the salt).

Something went wrong in this run. The caps immediately got some specks of concentrated dye on them; those did not fade during 50 min of simmering. Could be due to the late addition of salt but I really suspect that the dye wasn't completely dissolved before I threw in the caps.

Afterwards, the caps darkened a bit on drying, and now they look more gold-brown than yellow, especially the ones that were grey before. Well, the dye is called golden glow after all. These are the only dyed caps that I'm unhappy with mainly due to the ugly specks and stains.

Results:

Look at all these funky colors on top of some squishy MY switches! and those 4 model M caps! I'm rather pleased in general, only the failed yellows are a pity.

Here's the most important picture, a key matrix

The sides of the IBM caps were sligthly warped but they still fit very well on their stems. Only tighter than before.

Conclusions & recommendations:

*Dyeing PBT caps with Dylon universal / multi-purpose dye works.

*The color doesn't rub off. No blue fingers so far.

*The Cherry caps keep their shape while the IBM M caps are slightly bent inwards. Don't be alarmed, they still fit on their stems very well.

*Some dyes obviously are absorbed better than others.

*Clean and degrease your pan! And your caps!!

*Dissolve the dye completely before adding the caps.

*Aluminium pans are generally a bad choice as this metal corrodes in acid or basic aqueous solutions.

*Quite some dye stuck to my pan due to its rough surface which made cleaning very difficult. I suggest using a smooth stainless steel pan or even better an enamel pan or a large glass beaker.

*I'm still not sure if the salt is necessary for dyeing key caps but it won't hurt to add it. BTW, it is absolutely necessary when dyeing textiles.

Future plans:

*The dye solutions were a bit heterogeneous. Next time I will try a larger volume (1 L water) and less salt (10 g). I'll also experiment with acetic acid as mordant instead of salt. All that will be done in a non-aluminum pan.

*I need to get a thermometer...

*Dylon multi-purpose dye, just as Rit dye, is a mixture of components: It consists of a reactive dye for cotton and rayon (probably useless for key caps), further an "acid dye" component for nylon and wool and possibly also a dispersion dye. I think it's the latter two that do the trick for the caps. It could be worthwhile to look for a source of pure acid dyes or disperse dyes that are designed for polyesters. Technically spoken, PBT is a polyester but it's rather different from the most common polyester, PET (polyethylene terephthalate) PET is the raw material for polyester textiles like your fleece sweater but also for soft drink bottles. My guess is that you can color PBT with dyes that are not able to penetrate PET.

Sources & links:

*Dylon multi-purpose dye (Dutch site): http://www.dylon.nl/products/verven/multi-purpose-tins/

*Dylon (English site, only shows the large 500 g tins): http://www.dylon.co.uk/product.php?alia ... e-dye-500g

*A great site about dyeing, lots of information: http://www.pburch.net/dyeing.shtml

*About Rit and Dylon multi-purpos dyes: http://uk.answers.yahoo.com/question/in ... 016AAkeooD

*Geekhack example of dyeing Model M caps with Rit: http://geekhack.org/showwiki.php?title=Island:15277

edit: removed some macabre typos