WHAT a beauty this is! It is always nice to get a typing example on video (if you have time). I know there are already a bunch out there, but I can't get enough of these boards. I have cream dampened ones in an AEKII but this board just sounds completely different (yes - I'd say - much better)

Custom Polyurethane Keycaps by Keymacs

- darkcruix

- Location: Germany

- Main keyboard: Brand New Model F F77 Keyboard

- Main mouse: Logitech MX Master

- Favorite switch: Ellipse version of Buckling Spring / BeamSpring

- DT Pro Member: 0209

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

Guys, I have some bad news. After some more extensive tests, I have run into an unexpected problem. Without going into technical details, I am not able to precisely mill the mount in the center of keycaps. I tried to get the deviations ≤0.05mm but no matter how hard I try, the best result is ≈0.2mm. That may sound like a small difference but it is clearly visible. One of the immediate consequences is that my keycaps do not have walls with the same thickness. Instead of heaving 2mm on all sides, I have, for instance, 1.8mm and 2.2mm—this is something clearly visible and, more importnatly, it may affect the function. If two such keycaps meet side by side and both are off-center in the opposite directions, they can actually stratch each other when pressed.

The trouble is that it is not something that can be easily fixed or avoided (at least not with the equipment I have). The problem is consistency and there seem to be just too many variables in play (material shrinkage and expansion of both the moulds and the casted keycaps and the fact that the clusters are held by a fixture-in-fixture which add some imprecision). Therefore, I am cancelling ‘keycaps as products’ on my web and continue just with the Alps-only Keymacs keyboards.

On the other hand, it is not all bad news: I am still able to make legends with the new technique and cast the Alps stems as before, it is just a matter of one more resin casting. I will use the technique to make custom legends on Keymacs keyboard, including the legend on the grey function keys that have been blank so far. I have some progress in this direction and will post in the Keymacs keyboard thread.

The trouble is that it is not something that can be easily fixed or avoided (at least not with the equipment I have). The problem is consistency and there seem to be just too many variables in play (material shrinkage and expansion of both the moulds and the casted keycaps and the fact that the clusters are held by a fixture-in-fixture which add some imprecision). Therefore, I am cancelling ‘keycaps as products’ on my web and continue just with the Alps-only Keymacs keyboards.

On the other hand, it is not all bad news: I am still able to make legends with the new technique and cast the Alps stems as before, it is just a matter of one more resin casting. I will use the technique to make custom legends on Keymacs keyboard, including the legend on the grey function keys that have been blank so far. I have some progress in this direction and will post in the Keymacs keyboard thread.

- darkcruix

- Location: Germany

- Main keyboard: Brand New Model F F77 Keyboard

- Main mouse: Logitech MX Master

- Favorite switch: Ellipse version of Buckling Spring / BeamSpring

- DT Pro Member: 0209

Thanks a ton for all the effort you put into this so far. I know that these things are a tough pill to swallow, when you already feel you are there.

Your keycaps are insanely great! Actually, all of your products are insanely great.

This message is also the cause, why I have so much trust in your products - you won't sell sub-optimal results.

Thank You!

Your keycaps are insanely great! Actually, all of your products are insanely great.

This message is also the cause, why I have so much trust in your products - you won't sell sub-optimal results.

Thank You!

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

What he said.

And if you’re looking for soul killing sharks whose idea of a once-in-year splurge on a full keyset is $100, then I also say hi.

And if you’re looking for soul killing sharks whose idea of a once-in-year splurge on a full keyset is $100, then I also say hi.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

I think this thread deserves an update. You have probably noticed from my Keymacs keyboard thread that I have finally fine-tuned the new process and I am able to make full Symbolics as well as arbitrary legends on my keys. That is the good news, I am really excited about that because I have put substantial effort (and cash) in it.

So far, I have made about three full sets and that gave me some estimation of the manufacturing difficulty. And this is the bad news. It is slow as hell. The keycaps with legends are actually triple shots (the first shot being the keycap profile, the second one being the legend and the third one being the stem) and each such a key requires three rounds of resin casting and three rounds of machining, separated by hand processing that includes repeated cleanings, soaking in separators, manual deburring with micro tools under a microscope, … Considering the fact that the silicone moulds must be repeatedly recreated, the average time spent on making a single keycap is more than 1 hour (the cure and machining times excluded). This, of course, is insane. The conclusion is that there is absolutely no way I can turn this process into even marginally profitable keycap-making service.

The only option for me is to keep the Keymacs project as it is (keycaps only as a part of a full keyboard kit). Sorry for giving you false hopes earlier but I clearly underestimated the difficulty of the process. I guess I have been seduced by the dark side of the keycaps.

This, of course, is insane. The conclusion is that there is absolutely no way I can turn this process into even marginally profitable keycap-making service.

The only option for me is to keep the Keymacs project as it is (keycaps only as a part of a full keyboard kit). Sorry for giving you false hopes earlier but I clearly underestimated the difficulty of the process. I guess I have been seduced by the dark side of the keycaps.

So far, I have made about three full sets and that gave me some estimation of the manufacturing difficulty. And this is the bad news. It is slow as hell. The keycaps with legends are actually triple shots (the first shot being the keycap profile, the second one being the legend and the third one being the stem) and each such a key requires three rounds of resin casting and three rounds of machining, separated by hand processing that includes repeated cleanings, soaking in separators, manual deburring with micro tools under a microscope, … Considering the fact that the silicone moulds must be repeatedly recreated, the average time spent on making a single keycap is more than 1 hour (the cure and machining times excluded).

Spoiler:

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

I am not really sure there is a room for another profile on the market, the initial investments are very high. Especially considering ALPS, I think it is just not economically viable. If I were interested in standard ANSI/ISO, I would just buy Tai-Haos or wait for another DCS group buy.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

Since this is not directly related to lisp keyboards, I will post it here. I made a quick sound comparison of the keycaps on MX clones. In particular, I have used a hand-wired keyboard I built a couple of years ago with 1st gen. NK_ Creams:

- dcopellino

- Location: Italia - Napoli

- Main keyboard: IBM 4704 F400 brushed chrome

- Main mouse: Logitech laser wired

- Favorite switch: Buckling spring

- DT Pro Member: 0229

- Contact:

Click and Thock. It's just the case to say.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

So, guys, it is nearly the end of the year and it is time to utter something positive, right? I have been working on improving the keycap-making process because I still want to make keycaps with milled stems. It is the best possible way in terms of the versatility. It seems I have resolved the issues with precision and I have already made a couple of keycap sets for Keymacs keyboards that are made completely with the new technique. In the end, the process is not as simple as I originally hoped for but it is not too complicated either. More tests and tweaking are needed before I re-announce keycap sets as a product, though. In the meantime, you can enjoy my new manufacturing video:

Obviously, I cannot offer this a service because there is always a possibility to damage keycaps but I think it is a nice suggestion for those who have small CNCs and a plenty of time…

Obviously, I cannot offer this a service because there is always a possibility to damage keycaps but I think it is a nice suggestion for those who have small CNCs and a plenty of time…

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

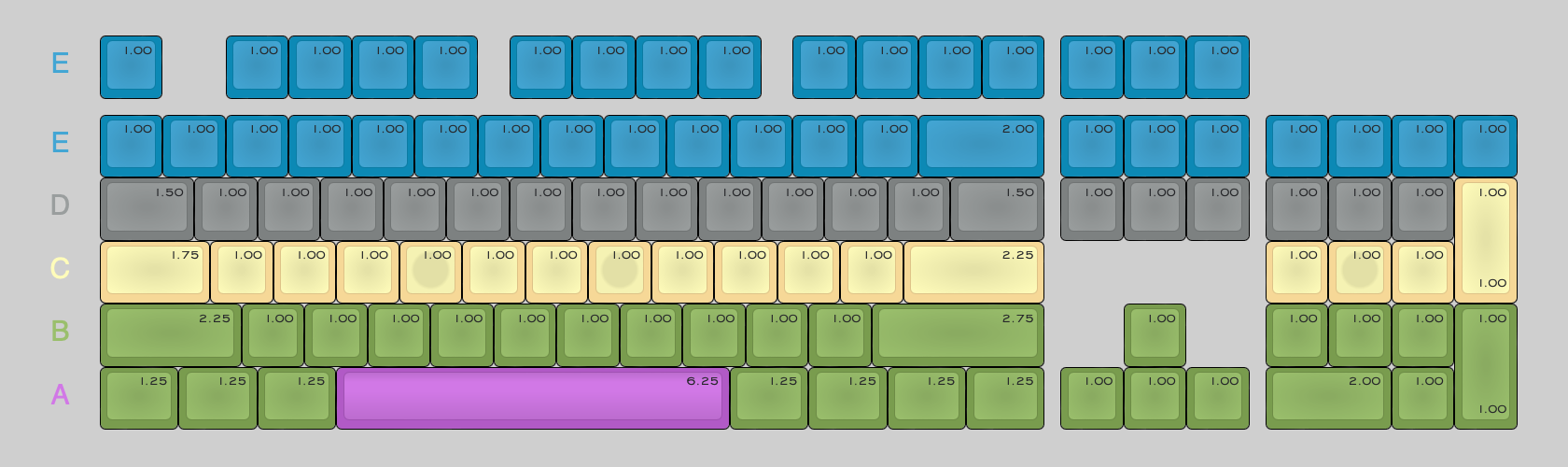

Okay folks, I am accepting orders for keycaps again.  Sorry for the confusion in this thread but after a long time I was able to refine the process and it is actually doable the way I intended. So, in short, I am indeed able to make keycap sets with almost any mount. All the keyboards I made in the last year or so were made with this new technique. I have substantially extended the set of keycap bases so that I can make keycaps for common (modern) layouts. The first MX-compatible set went to Jae—it is an extended version of the UK ISO full size set which includes concave+convex modifiers, ANSI compatibility keys, split spacebars, and a couple of odd keys (like the caps lock variants), you can look at the first impression in his unboxing video.

Sorry for the confusion in this thread but after a long time I was able to refine the process and it is actually doable the way I intended. So, in short, I am indeed able to make keycap sets with almost any mount. All the keyboards I made in the last year or so were made with this new technique. I have substantially extended the set of keycap bases so that I can make keycaps for common (modern) layouts. The first MX-compatible set went to Jae—it is an extended version of the UK ISO full size set which includes concave+convex modifiers, ANSI compatibility keys, split spacebars, and a couple of odd keys (like the caps lock variants), you can look at the first impression in his unboxing video.

- depletedvespene

- Location: Chile

- Main keyboard: IBM Model F122

- Main mouse: Logitech G700s

- Favorite switch: buckling spring

- DT Pro Member: 0224

- Contact:

You just love making us drool...lispnick wrote: ↑20 Jun 2024, 17:27Okay folks, I am accepting orders for keycaps again.Sorry for the confusion in this thread but after a long time I was able to refine the process and it is actually doable the way I intended. So, in short, I am indeed able to make keycap sets with almost any mount. All the keyboards I made in the last year or so were made with this new technique. I have substantially extended the set of keycap bases so that I can make keycaps for common (modern) layouts. The first MX-compatible set went to Jae—it is an extended version of the UK ISO full size set which includes concave+convex modifiers, ANSI compatibility keys, split spacebars, and a couple of odd keys (like the caps lock variants), you can look at the first impression in his unboxing video.

(how's the custom color aspect of the keycap making going?)

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

My standard color schemes are old-style symbolics (black/gray with white/black legends) and cadet (gray/blue with white/black legends). I have also make a single specimen in the new-style symbolics color scheme (black on grey + red on grey for modifiers). I make experiments with other colors as well:depletedvespene wrote: ↑21 Jun 2024, 16:55[(how's the custom color aspect of the keycap making going?)

In general, the lighter the color the greater the need to make reworks. The base pigments cannot be always perfectly mixed with the polyurethane precursors and this may lead to tiny darker spots on the keys. Just at this moment, I am doing a third rework of a gray spacebar because the first two had sub 0.1mm spots (what's worse, there was exactly one spot on each of the spacebars

- AJM

- Location: Germany

- Main keyboard: Geonworks W1-AT

- Favorite switch: Lichicx Lucy

- DT Pro Member: 0231

I'm still very intrigued. I hope you don't throw keycaps with such minor defects away. Could you sell them as samples at reduced prices, so one could have a closer look, before one commits to order a whole set? If you're worried about your reputation by giving out less than perfect caps, you might mark them somehow as prototype.

And do you have a list of already available legends/moulds? And could one get a quote by selecting the desired caps from that?

And do you have a list of already available legends/moulds? And could one get a quote by selecting the desired caps from that?

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

I reuse the keycaps for further prototyping like experimenting with new mounts, etc. The thing that prevents me from sending samples is basically the shipping costs. Most of my orders go to the US, the shipping costs (including the fees for the export paperwork) for a small package is about 50 EUR (I send by FedEx because Czech Post/USPS is a deadly combination). So I am not sure if anyone wants to pay me a few bucks for samples and 50 EUR for the shipping. If you are from the EU, the shipping cost is lower but there is 21% VAT. For the same reason, I do not take 'small orders' (with the exception of additional keys or repairs for customers who already have my keyboard/keycap set), 60% keycap set is minimum (or perhaps a slightly smaller ortho would also be acceptable). But I can actually make a batch of sample keys (e.g. ESC keys) and offer it through a vendor, if there is an interest.AJM wrote: ↑22 Jun 2024, 12:26I'm still very intrigued. I hope you don't throw keycaps with such minor defects away. Could you sell them as samples at reduced prices, so one could have a closer look, before one commits to order a whole set? If you're worried about your reputation by giving out less than perfect caps, you might mark them somehow as prototype.

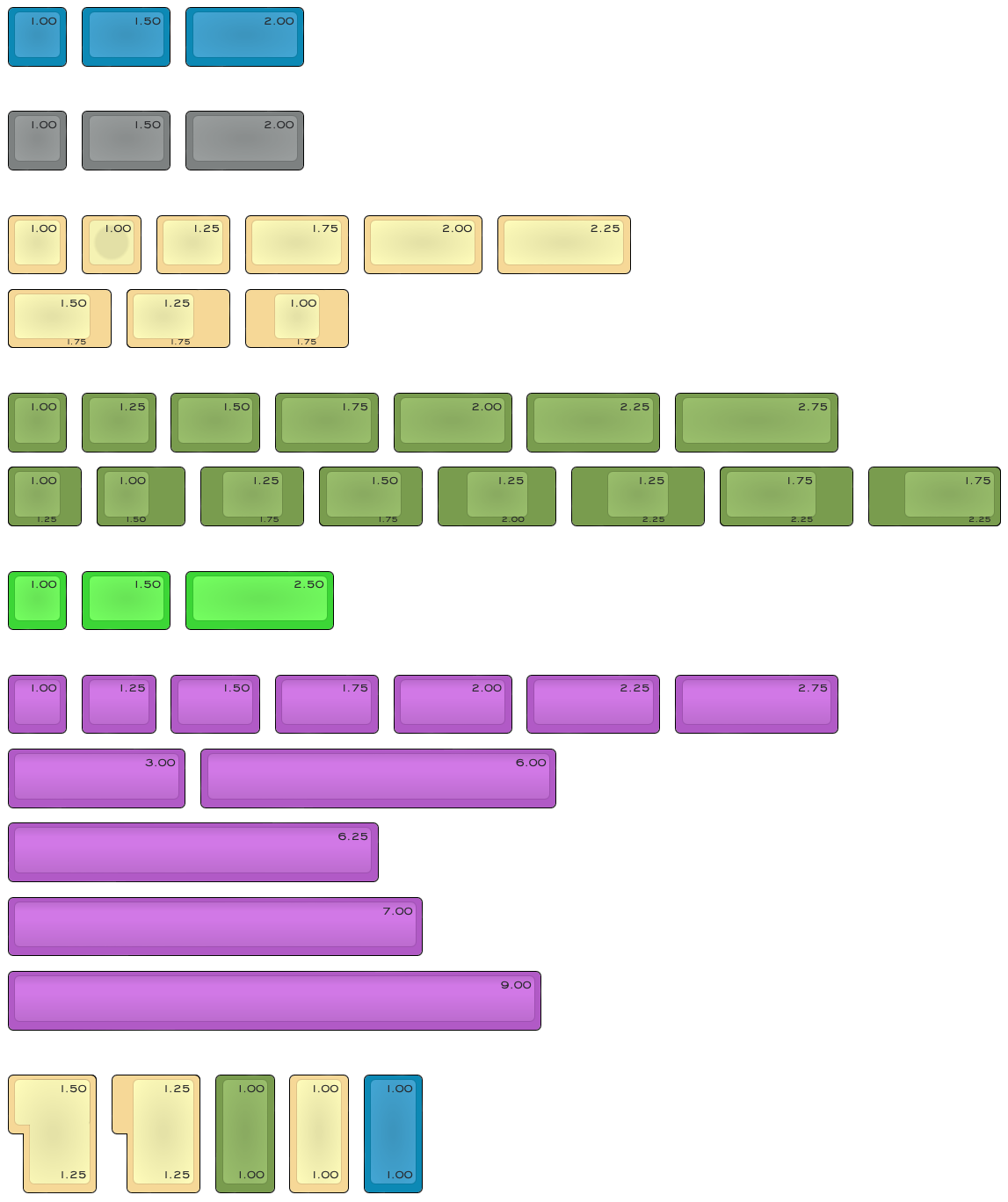

The profile supports 6 different 'rows': A (spacebars/convex keys), B (ZXCV row, concave modifiers), C (home row), D (QWERTY row), E (numbers and F-keys), and X (dummy keys):

The available sizes for each row are the following (KLE file is attached):

The dummy keys (neon green in the picture) are intended as covers for unused keys (typically to make a poor man's winkeyless keyboard by covering the windows keys). I do not have bases for big-ass and medium-ass enters at the moment but I am willing to put them in production as soon as I get a serious request. The same applies for missing key lengths, more exotic stepped keys, etc., but there may be a surcharge covering the extra manufacturing costs.

- Attachments

-

- kss-available-20240620.zip

- KLE file of the available keys

- (711 Bytes) Downloaded 53 times