I accidentally acquired an XT, an AT and was loaned one of the new reproductions.

So now I have 2 XTs(older: "4870-10313"/oldest chip date 8411, newer: F3 5275, oldest chip 8538, controller has "0686" on it), AT (F4 4924/8427), F122 (F6 5218, controller desoldered and I have 4 of those, so..) and the chinese copy.

XT barrels are virtually indistinguishable - although surface polish of barrel underside is sliiiiightly different.

AT barrels are just like XT, but with barrel-side key.

F122 barrels is where it starts to get interesting: they have a fillet (rounding) on top, making the key interface ring (the part that contacts the key when bottomed out) noticeably thinner. It also has a more complex flipper retainer notch - probably to reinforce it a bit, but it's not like that part actually _needed_ any reinforcement..

So it really looks like F122 had spiffier molds (better presses maybe, capable of exquisite-r details?)

- PXL_20230605_063316436.jpg (2.12 MiB) Viewed 14568 times

- PXL_20230605_063658862.jpg (2.07 MiB) Viewed 14568 times

Chinese clone seems to be inspired by AT barrel design, going for

* seemingly thicker key interface ring - good!

* thicker back wall of the base (1.1 vs 1.0mm - for a moment, I thought that it's thinner side walls of the flipper chamber - but no) - good-ish? No real difference.

* certain simplification of the stem grippers access from below (likely to improve mold manufacturability) - no difference, nothing touches that part ever.

* simplifying the internal barrel chamfers a-la model M - not critical AT ALL, nothing contacts those parts either.

* tapering the outside of the barrel base a bit (likely to improve part removal - in fact, original IBM barrels seem to be a _real_ bitch to get off the mold - lots of LONG cylinders and "vertical" lines you can't taper without sacrificing stem retention stability) - no difference, may be rebound sound a bit.

* using harder plastic - good!

* but rougher surface (not sure if bad, actually - it's not _that_ rough)

Not bad overall, but somewhat scratchier/draggier vs originals. Especially if the key doesn't have an upper stabilizer (like unicomp keypad enter - but yeah, let's not even talk about unicomp

)

* Oh, and significantly larger radius of the barrel base (yes, barrel base isn't bent upwards at some point - whole bottom of the barrel is molded as one large R300-ish arc with the axis of the barrel being the axis of that arc, and center point way above the barrel.

- PXL_20230605_065139077.jpg (2.16 MiB) Viewed 14568 times

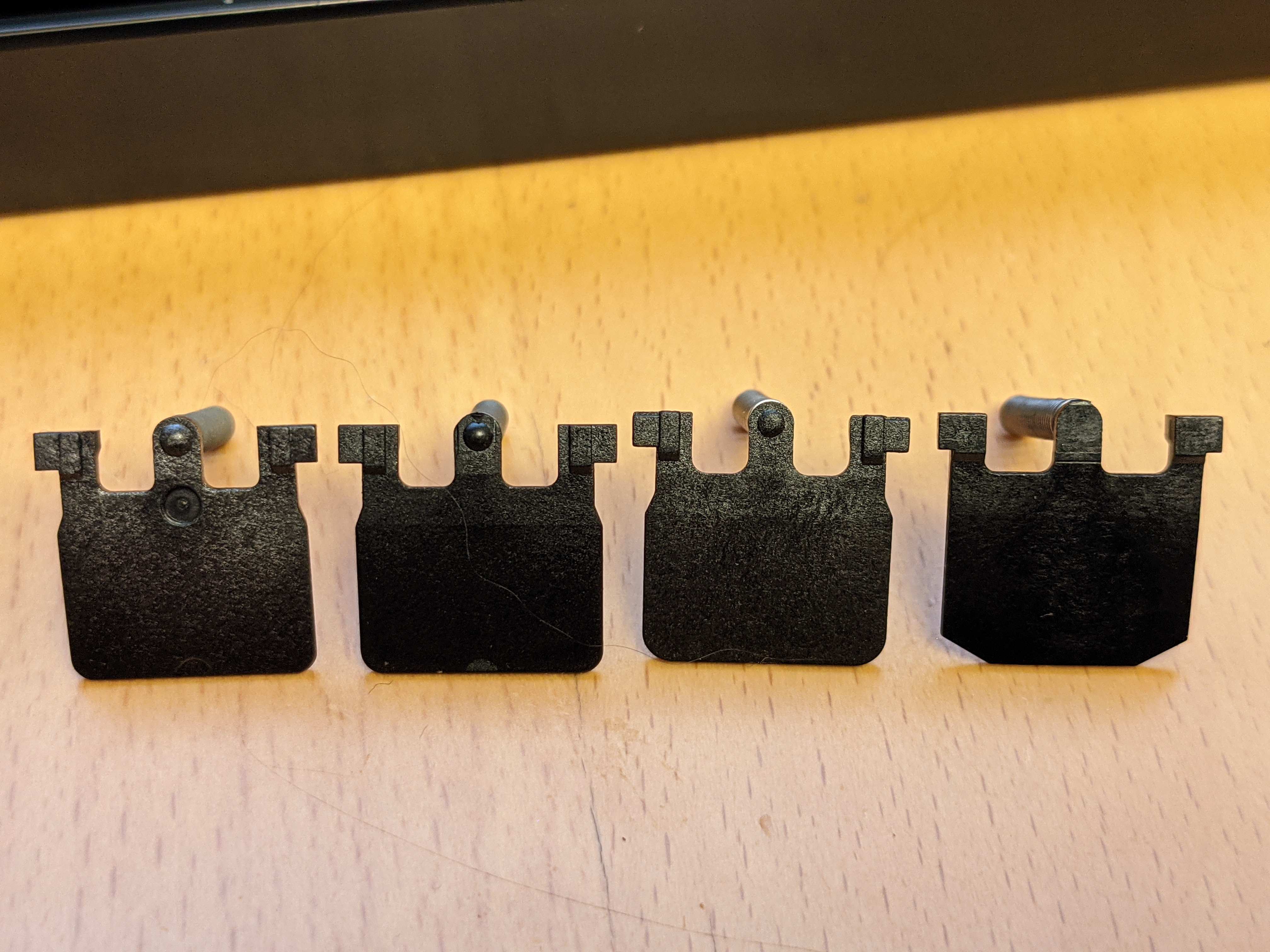

Flippers were more of a surprise: old XT had this dip in the middle (probably runner) and a larger ball under the spring support (but still not load-bearing). Newer XT and F122 flippers are indistinguishable. But AT.. AT was a total surprise: _very_ smooth plastic - almost slippery, _very_ simplistic forms - literally a model M flipper support married to a model F's flipper proper with crudely chopped off corners.

Chinese clone tries to reproduce F122 flipper, but it's thicker (1.0mm at the end, 1.4mm at the "base" vs 0.9/1.2) and has all the edges rounded (again, can be a mold manufacturability improvement) - like, the pivot on the original flippers (even on AT) is razor-sharp 135 degrees, but the clone adds R0.1-ish fillet at that corner. May be this greatly extends the life of the mold, who knows. Doesn't seem to have a huge effect on anything.

Next stop - comparing keycaps (not to unicomp, I promise. F122 will also be disqualified, as it has two-piece keys throughout for some strange reason).