New Buckling Spring Design

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

... with features that some will hate.

When i designed the XTant, for each element/feature i had to settle on one solution. That does not mean that i considered only one solution, but that I went with the idea I thought was truest to the design goal - reuse as much as possible and preserve the spirit of the original XT.

Folks that know me know that i don't throw very much out. I'm always thinking about how i can make useless things more useful. So I have all these discarded ideas for elements/features that i would like to try out. Buckling spring purists will likely hate them all, but i believe that there is value in trying them out. So when i saw Big Blue Saw was having a "Spring" design contest, i entered this design. I am one of the finalists and one of two designs that fit the contest theme "Spring", so i optimistic that i'll get some bonus funding.

I will talk about the new design elements when i post next.

When i designed the XTant, for each element/feature i had to settle on one solution. That does not mean that i considered only one solution, but that I went with the idea I thought was truest to the design goal - reuse as much as possible and preserve the spirit of the original XT.

Folks that know me know that i don't throw very much out. I'm always thinking about how i can make useless things more useful. So I have all these discarded ideas for elements/features that i would like to try out. Buckling spring purists will likely hate them all, but i believe that there is value in trying them out. So when i saw Big Blue Saw was having a "Spring" design contest, i entered this design. I am one of the finalists and one of two designs that fit the contest theme "Spring", so i optimistic that i'll get some bonus funding.

I will talk about the new design elements when i post next.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

For my contest submission, i outlined 5 features that the new keyboard would have. I just added a 6th.

#1: New case and plates

For the XTant, I re-used as much as possible from the “donor” keyboard. The new design will use as little as possible. The case will be a 4 layer sandwich of acrylic sheet. This is a simple, inexpensive, and proven method for making custom cases, but has never been used for a buckling spring keyboard case.

#2: 65% layout

You guys know that this is totally a preference thing. I like my layout better than Unicomp's promised "compact" layout. It uses stepped caps to demarcate the arrow cluster without leaving empty space. None of the caps are special order.

http://www.keyboard-layout-editor.com/# ... c947584853

#3: Flat key platform

The IBM Model M2 and M15 are flat; others have a curve radius somewhere between 10 and 15 inches – which is pretty close to flat. The key cap tops are angled back which gives a stair step switch profile.

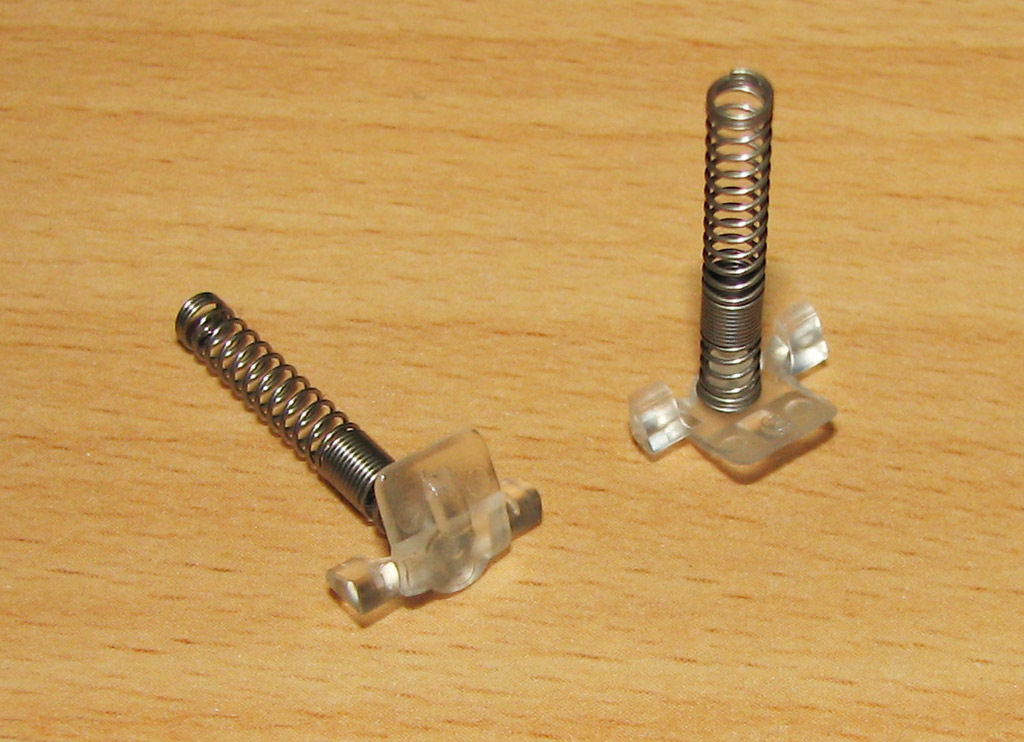

#4: M type buckling spring

Contact switches are robust, need no shielding, and the controllers are simple, small, and less expensive. Membrane switches are normally 2KRO, but I have already shown that diode can be used to achieve NKRO with membrane switches. I will use 10 TVS 8-way diode arrays for NKRO and use the same controller as the Infinity keyboard (100% programmable).

#5: Key back-lighting

This is not for everyone, but some folks love it. The closest a buckling spring keyboard has gotten to back-lighting was EL wire strung around the barrels. I think I can do better by LED edge lighting the acrylic case.

#6: Flipped keys for thumbs

Buckling spring caps tilt back about 8 degrees or so with the exception of Spacebar and "Code" keys which have a rounded top. I will be trying out "Erase-eze" style Space/Backspace using Shift caps (flipped, so tilted 8 degrees forward).

#1: New case and plates

For the XTant, I re-used as much as possible from the “donor” keyboard. The new design will use as little as possible. The case will be a 4 layer sandwich of acrylic sheet. This is a simple, inexpensive, and proven method for making custom cases, but has never been used for a buckling spring keyboard case.

#2: 65% layout

You guys know that this is totally a preference thing. I like my layout better than Unicomp's promised "compact" layout. It uses stepped caps to demarcate the arrow cluster without leaving empty space. None of the caps are special order.

http://www.keyboard-layout-editor.com/# ... c947584853

#3: Flat key platform

The IBM Model M2 and M15 are flat; others have a curve radius somewhere between 10 and 15 inches – which is pretty close to flat. The key cap tops are angled back which gives a stair step switch profile.

#4: M type buckling spring

Contact switches are robust, need no shielding, and the controllers are simple, small, and less expensive. Membrane switches are normally 2KRO, but I have already shown that diode can be used to achieve NKRO with membrane switches. I will use 10 TVS 8-way diode arrays for NKRO and use the same controller as the Infinity keyboard (100% programmable).

#5: Key back-lighting

This is not for everyone, but some folks love it. The closest a buckling spring keyboard has gotten to back-lighting was EL wire strung around the barrels. I think I can do better by LED edge lighting the acrylic case.

#6: Flipped keys for thumbs

Buckling spring caps tilt back about 8 degrees or so with the exception of Spacebar and "Code" keys which have a rounded top. I will be trying out "Erase-eze" style Space/Backspace using Shift caps (flipped, so tilted 8 degrees forward).

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Looks like a neat idea. Although after using the capacitative buckling spring switch, it would be hard to go back to the regular kind of membrane M type switch.

How will the sandwich be held together? I hope it isn't plastic rivets.

How will the sandwich be held together? I hope it isn't plastic rivets.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

The new case will be laser cut acrylic sheet. Hopefully, the contest will pay for it.

The bottom layer will be .125" thick clear acrylic. You will be able to see the PCB through it. The middle layer will be .25" clear acrylic. This goes on top of the PCB and around the barrel bases. It will act as a light pipe for the LEDs (mounted on the PCB). The holes will be tapped for #6 machine screw. It will also need some engraving for the LEDs and micro USB connector. The barrel frame layer will be .125" clear acrylic. This will be solvent bonded to the middle layer and also act as a light pipe directing the LED light to the barrel hole edges and hopefully create a pleasing glow under the key caps. The trim layer will be solvent bonded on top of the barrel frame and hide the screw holes. It might be .25" white, black, or clear acrylic - i haven't decided yet. White would be a good reflector to help focus the LED light to the cut edges. Black would be more athletically pleasing IMHO. I think that someone makes an acrylic sheet that is white or silver on one side and black on the other - that would be ideal.

The bottom layer will be .125" thick clear acrylic. You will be able to see the PCB through it. The middle layer will be .25" clear acrylic. This goes on top of the PCB and around the barrel bases. It will act as a light pipe for the LEDs (mounted on the PCB). The holes will be tapped for #6 machine screw. It will also need some engraving for the LEDs and micro USB connector. The barrel frame layer will be .125" clear acrylic. This will be solvent bonded to the middle layer and also act as a light pipe directing the LED light to the barrel hole edges and hopefully create a pleasing glow under the key caps. The trim layer will be solvent bonded on top of the barrel frame and hide the screw holes. It might be .25" white, black, or clear acrylic - i haven't decided yet. White would be a good reflector to help focus the LED light to the cut edges. Black would be more athletically pleasing IMHO. I think that someone makes an acrylic sheet that is white or silver on one side and black on the other - that would be ideal.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Sounds good. Although I would still prefer the capacitative switch, acrylic seems like an interesting idea for a case.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

6 flat head polycarbonate (clear) machine screws. The feet will be clear polyurethane.Redmaus wrote: ↑Looks like a neat idea. Although after using the capacitative buckling spring switch, it would be hard to go back to the regular kind of membrane M type switch.

How will the sandwich be held together? I hope it isn't plastic rivets.

The feel of a buckling spring is more dependent on the case construction than on the switch activation type. For example, a standard M feels different than an M2 or M15. An F feels the way it does because of the multiple metal plates and lack of rivets. As this case is unlike any other buckling spring keyboard, it will most likely feel similar but different.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Nice that they are screws and will make layout and opening/making modifications to the board easier.

I suppose you are right about the switches, but is the "ping" noise of a model F caused by the flipper slapping the PCB?

I suppose you are right about the switches, but is the "ping" noise of a model F caused by the flipper slapping the PCB?

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Who knows. I always thought it was it hitting the PCB but it could be a number of things. I wonder why anyone else hasn't replied yet?

- vivalarevolución

- formerly prdlm2009

- Location: USA

- Main keyboard: IBM Beam spring

- Main mouse: Kangaroo

- Favorite switch: beam spring

- DT Pro Member: 0097

Make it feel like the F switch, please.

- ramnes

- ПБТ НАВСЕГДА

- Location: France

- Main keyboard: KMAC LE

- Main mouse: Zowie AM

- Favorite switch: GPL 104 lubed 62g nixies

- DT Pro Member: -

I though a lot about a project like this, and I guess I'm not the only one.

Will you produce model M/F barrels/flippers clones to complete the board, or will they have to come from a donor board?

Also, like prdlm2009 and Redmaus, I'd love to get the model F feeling. I think you're right about this feel coming in a major part from the metallic parts of the board, but model F switches seems lighter and higher actuated than BS to me.

I really am impatient to see some results, good luck!

Will you produce model M/F barrels/flippers clones to complete the board, or will they have to come from a donor board?

Also, like prdlm2009 and Redmaus, I'd love to get the model F feeling. I think you're right about this feel coming in a major part from the metallic parts of the board, but model F switches seems lighter and higher actuated than BS to me.

I really am impatient to see some results, good luck!

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

It'll feel like an M2, I reckon. Which is a good thing if you choose it! I was impressed with mine. Never thought I'd like it.

Model F is all about those giant flippers. They carry more momentum than the chubby stubs on M. I suspect the construction of the M2 is the most like this, but it's just a guess. What's the sensing mechanism anyway? Membranes?

Model F is all about those giant flippers. They carry more momentum than the chubby stubs on M. I suspect the construction of the M2 is the most like this, but it's just a guess. What's the sensing mechanism anyway? Membranes?

- vivalarevolución

- formerly prdlm2009

- Location: USA

- Main keyboard: IBM Beam spring

- Main mouse: Kangaroo

- Favorite switch: beam spring

- DT Pro Member: 0097

Muirium wrote: ↑It'll feel like an M2, I reckon. Which is a good thing if you choose it! I was impressed with mine. Never thought I'd like it.

Model F is all about those giant flippers. They carry more momentum than the chubby stubs on M. I suspect the construction of the M2 is the most like this, but it's just a guess. What's the sensing mechanism anyway? Membranes?

It's membranes. Look at point #4.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

Yep, technically a membrane, but the bottom "sheet" will be a PCB with the controller, USB connector, and diodes surface mounted to it. The PCB mask layer might substitute for a middle sheet depending on thickness. The top membrane will be printed by inkjetflex.com and will connect to the PCB (and then to controller) with Z conductive tape. All that topped off with a new rubber mat from Unicomp.

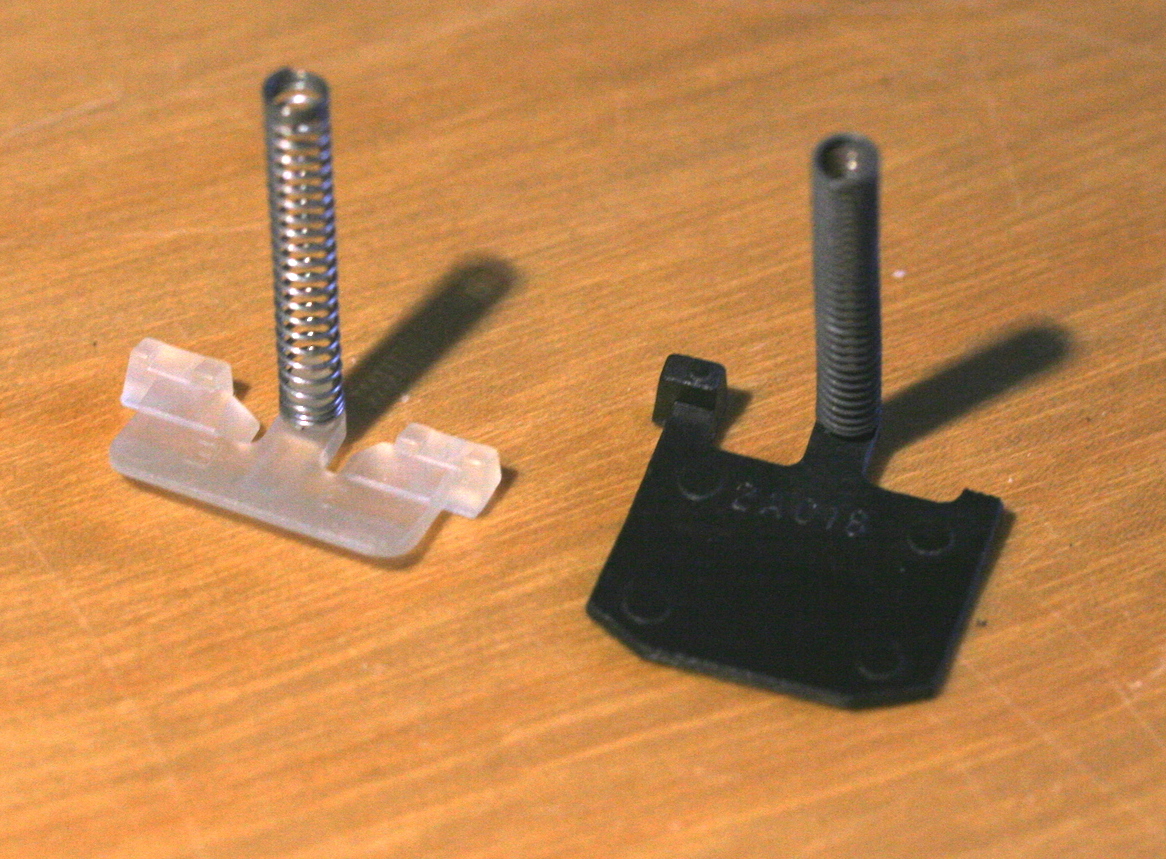

I'll be using vintage barrels for this, but I might ask for help finding a company willing to copy 30 year old IBM barrels. Polycarbonate barrels would look cool.

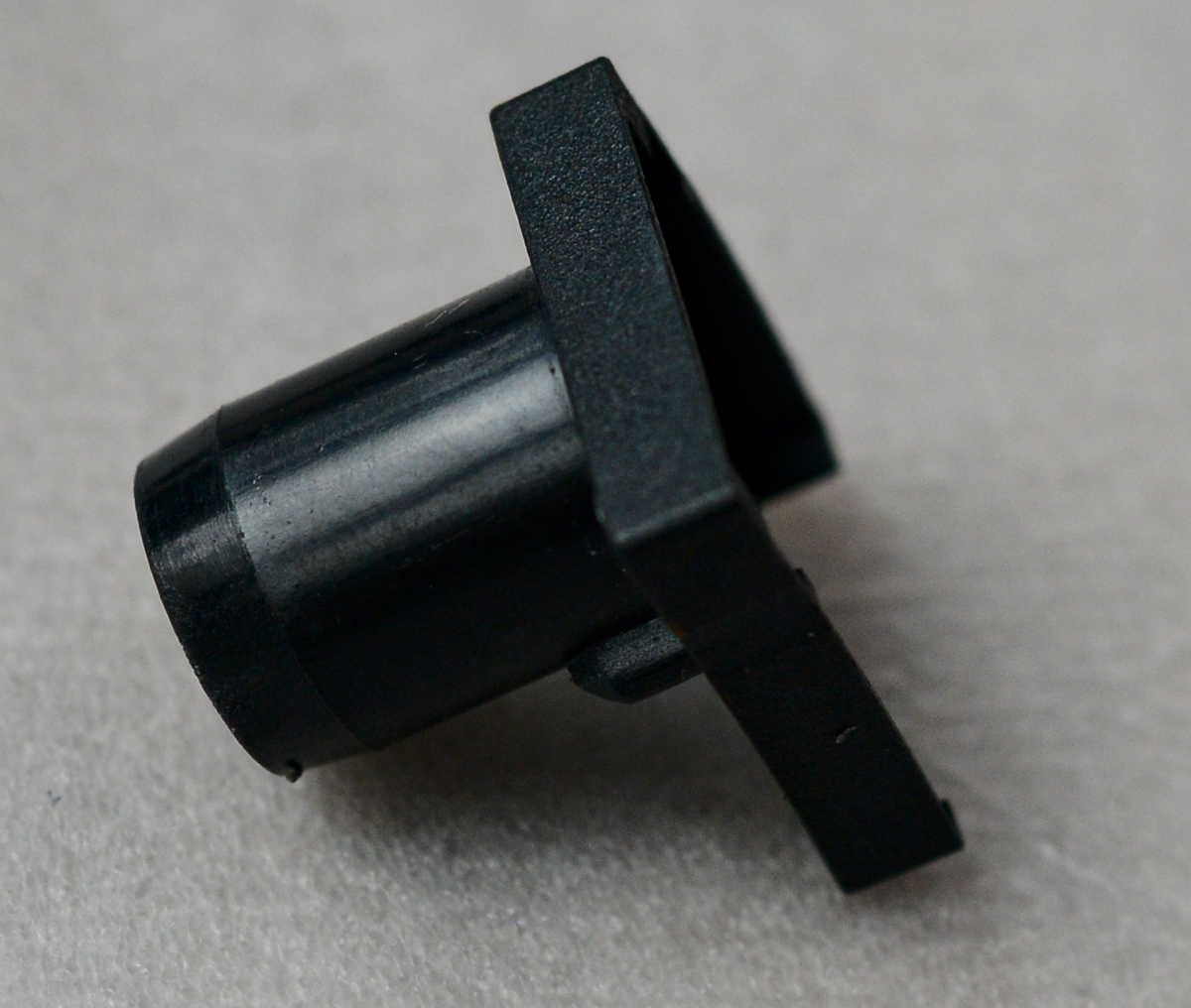

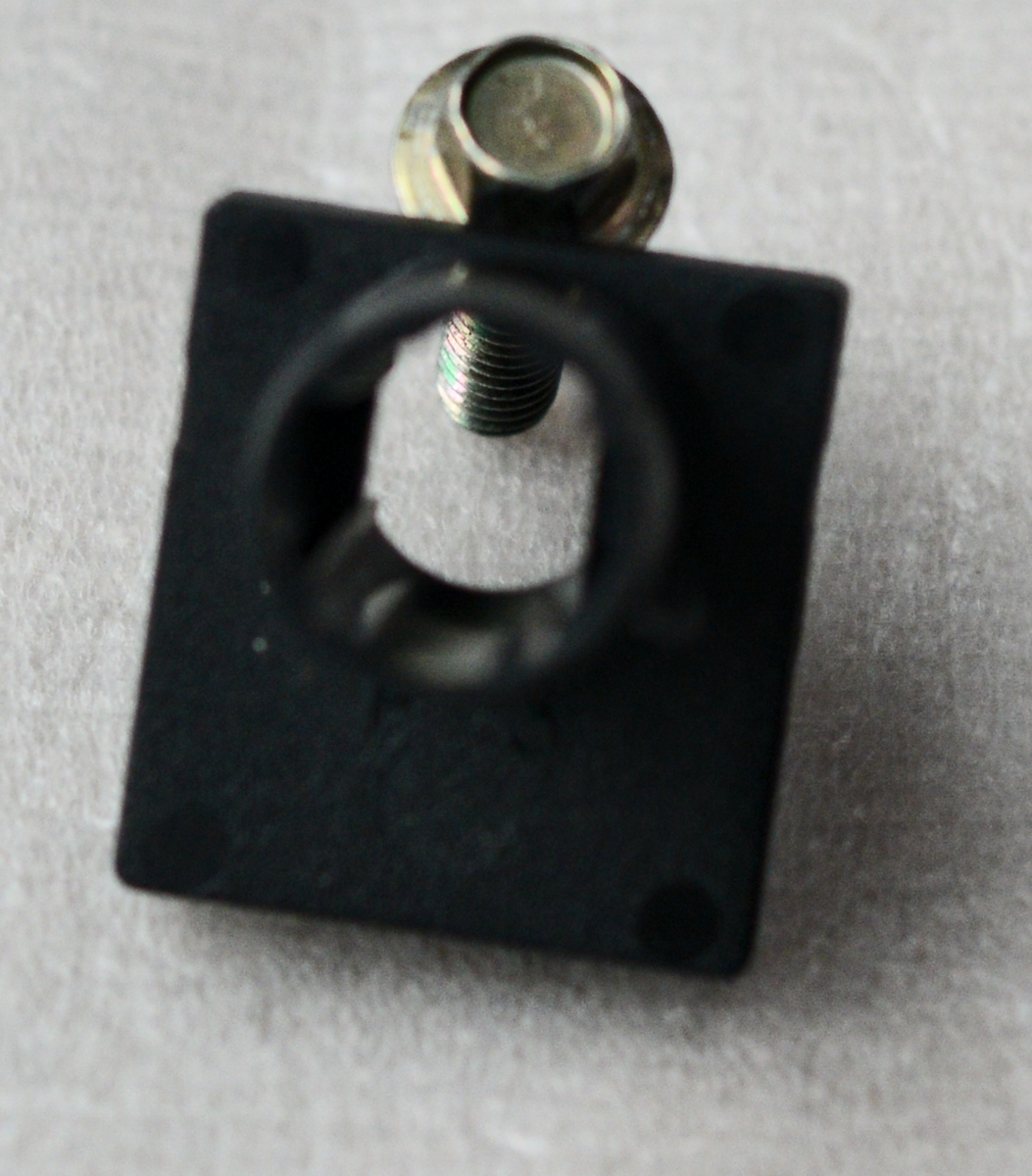

As for feel, the plates and barrels are held together much more like an F than an M (independent barrels fit into holes, plates held together only around perimeter). The top and bottom plates will be plastic, but much thicker than the plastic used for the M2.

I'll be using vintage barrels for this, but I might ask for help finding a company willing to copy 30 year old IBM barrels. Polycarbonate barrels would look cool.

As for feel, the plates and barrels are held together much more like an F than an M (independent barrels fit into holes, plates held together only around perimeter). The top and bottom plates will be plastic, but much thicker than the plastic used for the M2.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

Two comments/questions:wcass wrote: ↑ I'll be using vintage barrels for this, but I might ask for help finding a company willing to copy 30 year old IBM barrels. Polycarbonate barrels would look cool.

1.- Have you considered 3D-printing the barrels ?

2.- Have you considered using model m flippers with some metal added to use capacitors ?

If the 2.- would work and 1.- is possible, we may have a solution for which there are lot of spares.

It may require changes to the controller that we know.

Just an idea ...

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

From the various 3D printed components I've seen, 3D printing is poorly suited to smooth, low friction, strong structural tasks like buckling spring barrels. But perhaps there are better 3D print materials I haven't seen. I sure hope so! It makes for fine cases, but poor sliders.

Model M flippers could be coated to work with capsense. I think Model F flippers are a resin material that's coated, like their beamspring fly plate ancestors. But! I don't think that would necessarily help Model M's feel at all. Naturally someone needs to test this, but I reckon the size of those flippers is essential to the two different feels of each flavour of buckling spring.

Model M flippers could be coated to work with capsense. I think Model F flippers are a resin material that's coated, like their beamspring fly plate ancestors. But! I don't think that would necessarily help Model M's feel at all. Naturally someone needs to test this, but I reckon the size of those flippers is essential to the two different feels of each flavour of buckling spring.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

Sanding ?Muirium wrote: ↑From the various 3D printed components I've seen, 3D printing is poorly suited to smooth, low friction, strong structural tasks like buckling spring barrels. But perhaps there are better 3D print materials I haven't seen. I sure hope so! It makes for fine cases, but poor sliders.

I guess that the feeling of the F is a mix of bigger flippers and hitting a PCB instead of a plastic matrix.Muirium wrote: ↑Model M flippers could be coated to work with capsense. I think Model F flippers are a resin material that's coated, like their beamspring fly plate ancestors. But! I don't think that would necessarily help Model M's feel at all. Naturally someone needs to test this, but I reckon the size of those flippers is essential to the two different feels of each flavour of buckling spring.

Yes, it will probably feel different.

-

andrewjoy

- Location: UK

- Main keyboard: Filco ZERO green alps, Model F 122 Terminal

- Main mouse: Ducky Secret / Roller Mouse Pro 1

- Favorite switch: MX Mount Topre / Model F Buckling

- DT Pro Member: 0167

The larger flipper has more weight to it and it takes less force to bypass it think of it a bit like a longer leaver, its hitting a hard PCB supported by a metal frame in place of a plastic membrane supported by a much thinner frame.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

That's what exactly what I wanted to express. It will be difficult to fully emulate it, but on return, we would make the resulting system independent on old keyboards donating parts. I guess that it is worth trying it ... I wish I would have the required time.andrewjoy wrote: ↑The larger flipper has more weight to it and it takes less force to bypass it think of it a bit like a longer leaver, its hitting a hard PCB supported by a metal frame in place of a plastic membrane supported by a much thinner frame.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

@Andy: Yup, that's my intuition on the feel, too. But with the emphasis on the bigger flipper. Has someone tried installing M hammers in a Model F for a lark just to find out?

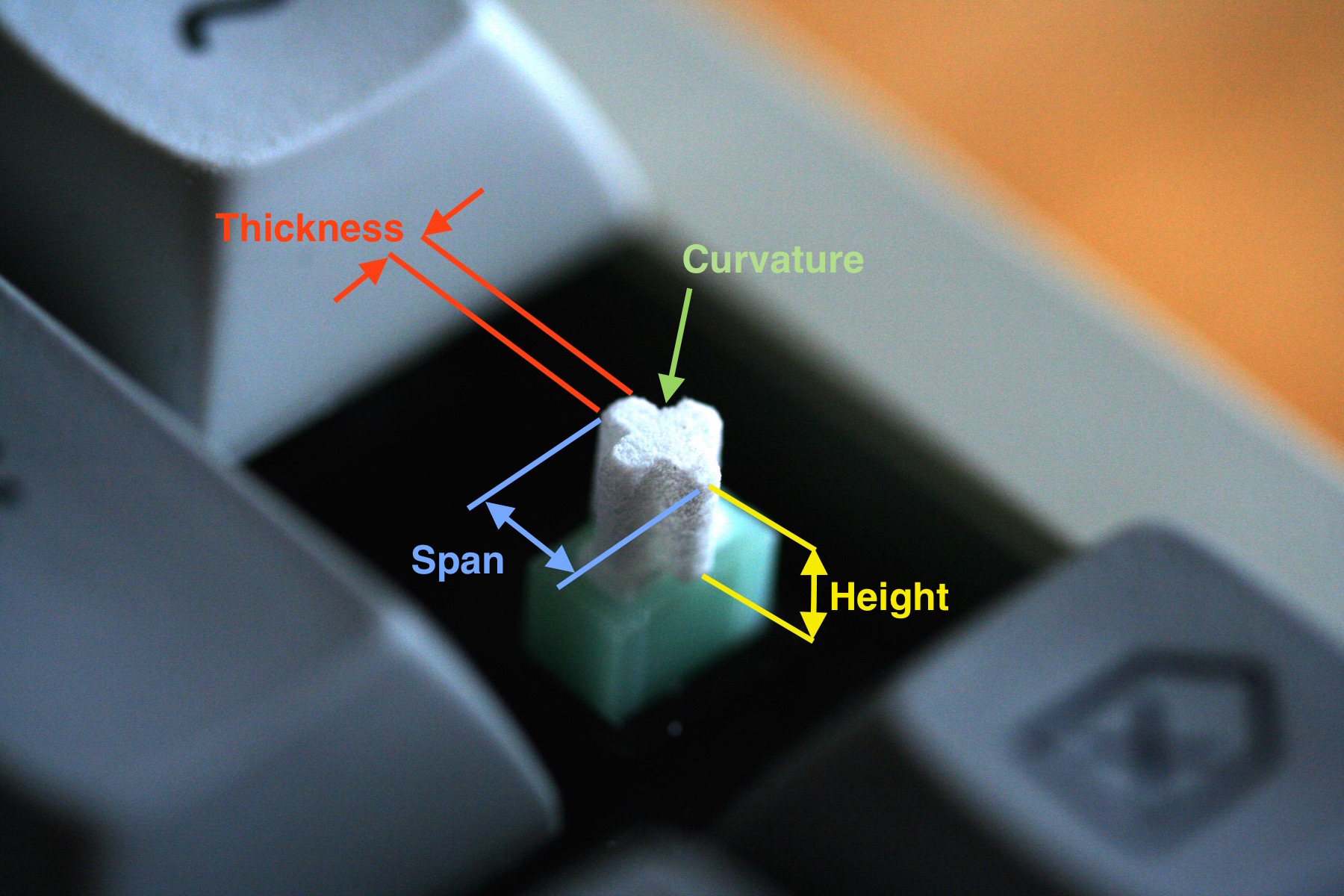

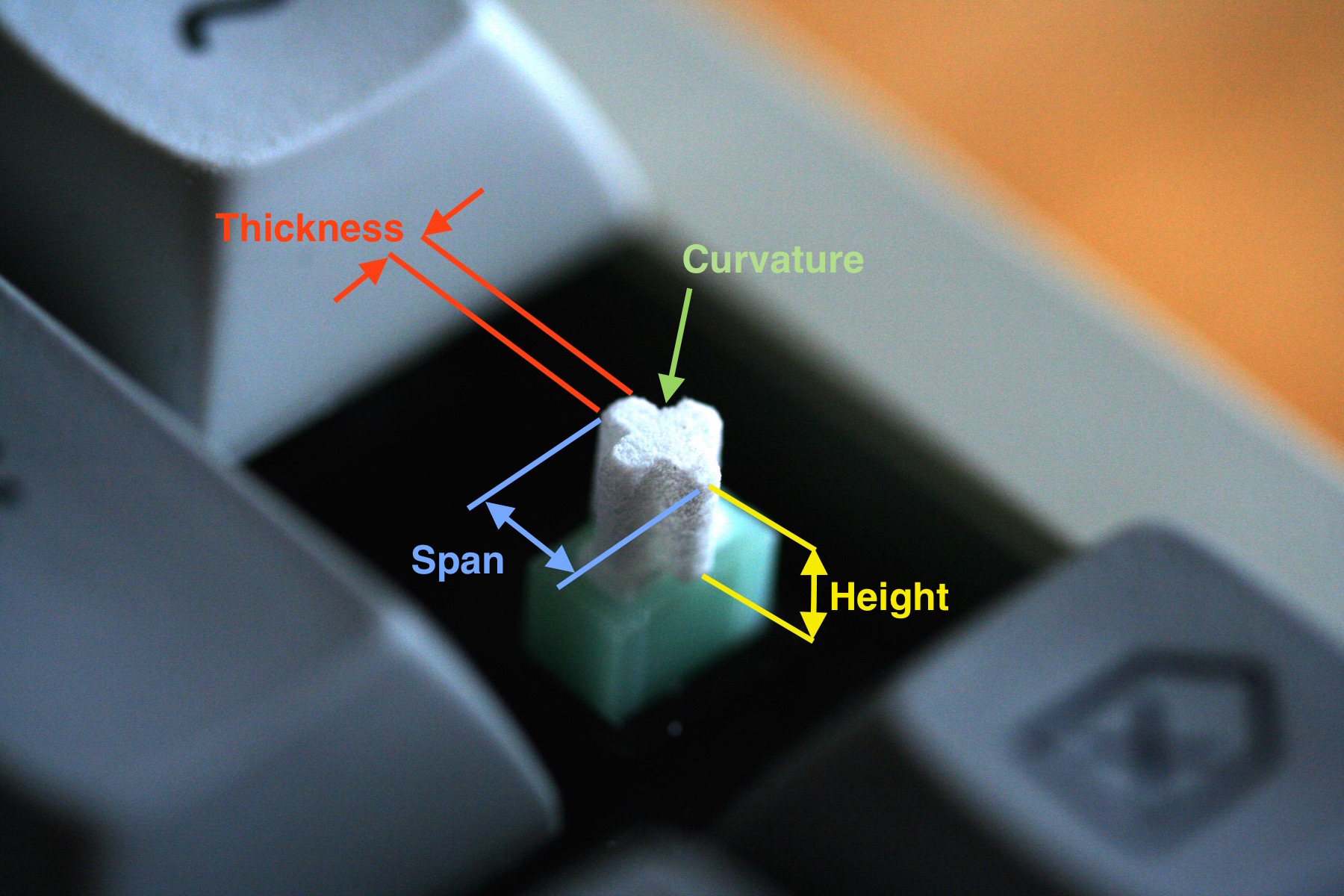

i$: The 3D printing material I've seen *crumbles* when compressed. That was the fundamental flaw in Mr Interface's Alps<>MX adapters. You can see their texture for yourself here:

Sanding it would leave nothing but a lot of mess, I fear! We really need stuff that comes out as strong as a thermoplastic or resin, not like this.

i$: The 3D printing material I've seen *crumbles* when compressed. That was the fundamental flaw in Mr Interface's Alps<>MX adapters. You can see their texture for yourself here:

Sanding it would leave nothing but a lot of mess, I fear! We really need stuff that comes out as strong as a thermoplastic or resin, not like this.

-

andrewjoy

- Location: UK

- Main keyboard: Filco ZERO green alps, Model F 122 Terminal

- Main mouse: Ducky Secret / Roller Mouse Pro 1

- Favorite switch: MX Mount Topre / Model F Buckling

- DT Pro Member: 0167

Mu , don't forget the F also has a lighter spring

EDIT

Taking of 3D printing , does anyone have a model that can be printed of an IBM top cap ( no slider) i want to print myself one in work

EDIT

Taking of 3D printing , does anyone have a model that can be printed of an IBM top cap ( no slider) i want to print myself one in work

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

If this is the case, we could find someone to produce them. Perhaps together with the flippers.Muirium wrote: ↑@Andy: Yup, that's my intuition on the feel, too. But with the emphasis on the bigger flipper. Has someone tried installing M hammers in a Model F for a lark just to find out?

i$: The 3D printing material I've seen *crumbles* when compressed. That was the fundamental flaw in Mr Interface's Alps<>MX adapters. You can see their texture for yourself here:

Sanding it would leave nothing but a lot of mess, I fear! We really need stuff that comes out as strong as a thermoplastic or resin, not like this.

This and xwhatsit's controller modified to the setup may open a new path.

Last edited by idollar on 19 Mar 2015, 22:28, edited 1 time in total.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

I think Matteo might, and Mr. Interface. Give 'em a PM.

I've swapped springs between M and F before. It doesn't make that much difference. I didn't have any Model F spare parts for a while, see. Those days were tough! Thanks again to Game Theory for coming to the rescue!

I've swapped springs between M and F before. It doesn't make that much difference. I didn't have any Model F spare parts for a while, see. Those days were tough! Thanks again to Game Theory for coming to the rescue!

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Actually, here's an interesting necro that just popped up:

Redmaus wrote: ↑Why exactly are these so terrible?

To graduate from a mere hypothesis, we need to put this to the test. Anyone got a date inside a Model F coming up? Put some M hammers in there and tell us what feel you get!Muirium wrote: ↑Looking at the mechanisms, I can take a guess:

These guys make Model M hammers look like mighty Model F flippers!

Certainly fits with my theory: more flipper = more feel.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

I guess that M hammers will not flip into the F barrel. They will not fit.Muirium wrote: ↑ To graduate from a mere hypothesis, we need to put this to the test. Anyone got a date inside a Model F coming up? Put some M hammers in there and tell us what feel you get!

I wanted to open my Fs for various reasons (space mod or F107 cleaning). I could try and report, but the result above is very probable.

In my opinion, the ideal solution would be to find a supplier of new parts. It should not be that difficult ...