Best replacement foam for keytronic foam and foil switches

-

PancakeMSTR

- Location: United States

- Main keyboard: Phantom TKL

- DT Pro Member: -

Hi,

I've got a keyboard which uses keytronic foam and foil switches and the foam (and foil, but I've got that figured out) has completely deteriorated, on every switch.

I can replace the foam pads, but I'm not quite sure what the best foam to use would be. Could anyone offer me advice? An amazon or link to some other place where I could buy the foam would be fantastic, too.

Thanks.

I've got a keyboard which uses keytronic foam and foil switches and the foam (and foil, but I've got that figured out) has completely deteriorated, on every switch.

I can replace the foam pads, but I'm not quite sure what the best foam to use would be. Could anyone offer me advice? An amazon or link to some other place where I could buy the foam would be fantastic, too.

Thanks.

-

Parak

- DT Pro Member: -

I haven't done it myself, but it'd be something of this sort:

http://vintageapple.org/lisainfo/Lukes_ ... repair.pdf

Basically pick closed cell if you want more stiffness but more durability, and open cell for the opposite. I'd probably go with the softest closed cell epdm/neoprene blend you can find of the appropriate thickness, which would be the thickness of existing pads or slightly less due to being not as compressible.

Also, go with adhesive backed foam for obvious reasons.

http://vintageapple.org/lisainfo/Lukes_ ... repair.pdf

Basically pick closed cell if you want more stiffness but more durability, and open cell for the opposite. I'd probably go with the softest closed cell epdm/neoprene blend you can find of the appropriate thickness, which would be the thickness of existing pads or slightly less due to being not as compressible.

Also, go with adhesive backed foam for obvious reasons.

- XMIT

- [ XMIT ]

- Location: Austin, TX area

- Main keyboard: XMIT Hall Effect

- Main mouse: CST L-Trac Trackball

- Favorite switch: XMIT 60g Tactile Hall Effect

- DT Pro Member: 0093

Foam and foil boards get a bad reputation here. They tend to be really nice linear boards (or okay tactile boards depending on the quality of the buckling rubber sleeve used). They're also capacitive and thus, with enough love and a controller replacement, inherently NKRO. Plus, they have built in down stroke damping. There are loads of vintage boards with really nice high-profiled ABS double shot spherical key caps, that people pass on.

The trouble is that most of the foam and foil boards you'll find have corroded foam and thus will have sensing issues.

I personally pass on most foam and foil boards because I don't love linears enough and don't want to do the repair myself. but I've got a bunch of them already, and maybe one day I'll fix them up.

I would use something like Super 77 contact adhesive to glue a sheet of the mylar to the non-adhesive side of the foam, use a leather punch from the mylar side to cut the pads, prep the old surface with isopropyl alcohol, and stick them on. I'd wear gloves for all of this.

Punching foam and foil pads is no harder than punching foam for a Model F rework. Same process really.

The trouble is that most of the foam and foil boards you'll find have corroded foam and thus will have sensing issues.

I personally pass on most foam and foil boards because I don't love linears enough and don't want to do the repair myself. but I've got a bunch of them already, and maybe one day I'll fix them up.

I would use something like Super 77 contact adhesive to glue a sheet of the mylar to the non-adhesive side of the foam, use a leather punch from the mylar side to cut the pads, prep the old surface with isopropyl alcohol, and stick them on. I'd wear gloves for all of this.

Punching foam and foil pads is no harder than punching foam for a Model F rework. Same process really.

-

PancakeMSTR

- Location: United States

- Main keyboard: Phantom TKL

- DT Pro Member: -

XMIT wrote: ↑Foam and foil boards get a bad reputation here. They tend to be really nice linear boards (or okay tactile boards depending on the quality of the buckling rubber sleeve used). They're also capacitive and thus, with enough love and a controller replacement, inherently NKRO. Plus, they have built in down stroke damping. There are loads of vintage boards with really nice high-profiled ABS double shot spherical key caps, that people pass on.

The trouble is that most of the foam and foil boards you'll find have corroded foam and thus will have sensing issues.

I personally pass on most foam and foil boards because I don't love linears enough and don't want to do the repair myself. but I've got a bunch of them already, and maybe one day I'll fix them up.

I would use something like Super 77 contact adhesive to glue a sheet of the mylar to the non-adhesive side of the foam, use a leather punch from the mylar side to cut the pads, prep the old surface with isopropyl alcohol, and stick them on. I'd wear gloves for all of this.

Punching foam and foil pads is no harder than punching foam for a Model F rework. Same process really.

Yeah but what foam?

-

PancakeMSTR

- Location: United States

- Main keyboard: Phantom TKL

- DT Pro Member: -

Hey thanks I'll look into that.Parak wrote: ↑I haven't done it myself, but it'd be something of this sort:

http://vintageapple.org/lisainfo/Lukes_ ... repair.pdf

Basically pick closed cell if you want more stiffness but more durability, and open cell for the opposite. I'd probably go with the softest closed cell epdm/neoprene blend you can find of the appropriate thickness, which would be the thickness of existing pads or slightly less due to being not as compressible.

Also, go with adhesive backed foam for obvious reasons.

- seebart

- Offtopicthority Instigator

- Location: Germany

- Main keyboard: Rotation

- Main mouse: Steelseries Sensei

- Favorite switch: IBM capacitive buckling spring

- DT Pro Member: 0061

- Contact:

I would NOT buy these I just wanted to show you that something like this is available:

http://www.ebay.de/itm/Victor-9000-SIRI ... Sw91NTtPPK

http://www.ebay.de/itm/Foam-Pads-for-Ke ... Sw91NTtPPK

You should be able to find more offers online make sure you know that they fit your Key Tronic keyboard these may not since they are for specific keyboards! What model is your Key Tronic?

http://www.ebay.de/itm/Victor-9000-SIRI ... Sw91NTtPPK

http://www.ebay.de/itm/Foam-Pads-for-Ke ... Sw91NTtPPK

You should be able to find more offers online make sure you know that they fit your Key Tronic keyboard these may not since they are for specific keyboards! What model is your Key Tronic?

-

TexElec

- Location: Texas

Just thought I would update this thread in case anyone else runs across it and needs to replace their foam and foil pads. We are currently making replacement pads that can be popped into place. They have been tested and used across many machines and the list is still growing. We have even had a customer repair a BTC keyboard successfully! We have been in contact with KeyTronic and even previous and current manufacturers of theirs. During this venture we were able to match our pads to an analysis completed on original pads by a metallizing company as well as matching the foam properly.  Here is a link if you'd like to save time repairing your keyboard:

Here is a link if you'd like to save time repairing your keyboard:

https://texelec.com/product/foam-capaci ... keytronic/

https://texelec.com/product/foam-capaci ... keytronic/

- JP!

- Location: United States

- Main keyboard: Currently a Model M

- Main mouse: Steel Series Sensei

- Favorite switch: Beam Spring

- DT Pro Member: 0194

- Contact:

Thanks for sharing. I have a few boards in dire need of new foam and this looks to be a great time saver.TexElec wrote: ↑09 Oct 2019, 19:20Just thought I would update this thread in case anyone else runs across it and needs to replace their foam and foil pads. We are currently making replacement pads that can be popped into place. They have been tested and used across many machines and the list is still growing. We have even had a customer repair a BTC keyboard successfully! We have been in contact with KeyTronic and even previous and current manufacturers of theirs. During this venture we were able to match our pads to an analysis completed on original pads by a metallizing company as well as matching the foam properly.Here is a link if you'd like to save time repairing your keyboard:

https://texelec.com/product/foam-capaci ... keytronic/

Also is this replacement foam superior to what was originally used?

- OldIsNew

- Location: US

- DT Pro Member: 0248

I've replaced the pads on a number of boards with polyurethane cushion foam, a Mylar emergency blanket and Elmer's Craft Bond glue. It's a softer foam and I personally like the feel. I've done 7 or 8 boards now using about half of one of the two foam pads that came in the $11 package I bought and maybe a quarter of a $3.75 emergency blanket plus one $2 craft glue stick. It's tedious but I actually enjoy doing it for some reason. I guess it just depends on whether or not you feel like spending the time - if not, the texelec pads do look tempting! I put some pics of the materials I've been using on the post I put up after working on my first F&F board here : viewtopic.php?f=7&t=17294

If you do make your own pads the conductive side of the Mylar foil should face away from the PCB.

If you do make your own pads the conductive side of the Mylar foil should face away from the PCB.

- Sangdrax

- Location: Hill Country

- Main keyboard: Harris 1978 Terminal

- Main mouse: Mammoth

- DT Pro Member: -

And you guys know I'm a fan of the hard foam. Super Glue brand precut archival grade foam tape ($1 and you need two rolls for the average full size board double stacked) and electrostatic discharge bags because they have both sides insulated and they're basically free and laying around if you do any other kind of electronic projects. Just takes an 11mm punch and about half an hour to get it done.

-

mr_a500

- DT Pro Member: -

I bought a set of the TexElec pads for my Victor 9000 - mostly because I am very lazy and didn't want to go through the tedium of making pads myself. So I was very happy that somebody did all that work for me and at a very reasonable cost. The replacement pads worked perfectly 100% on the very first test after installing.

One thing I did note while installing was that they were slightly thicker than the originals. I didn't think anything of it at the time, thinking that the originals were degraded, disintegrating and therefore would be thinner. When typing, however, I noticed a change in feel. The original (non-working) Victor 9000 feel was super-smooth and light, one of my all-time favourite keyboards - far nicer than my many other Key Tronic foam and foil keyboards. After the pad replacement, it felt like my least favourite Key Tronic foam and foil keyboard - too stiff. Possibly, the light & smooth feel that I liked was because the pads were degraded and it was never really that nice - or the replacement pads were slightly too thick for this keyboard, making resistance too great. Or maybe I tightened the keyboard screws too tight. Who knows?

I don't want to say anything bad about the TexElec pads because I think it's a great service they provide at a reasonable cost, helping restore many vintage keyboards that would otherwise be a pain in the ass to restore. Possibly there were variations in foam thickness for different keyboards of that era.

One thing I did note while installing was that they were slightly thicker than the originals. I didn't think anything of it at the time, thinking that the originals were degraded, disintegrating and therefore would be thinner. When typing, however, I noticed a change in feel. The original (non-working) Victor 9000 feel was super-smooth and light, one of my all-time favourite keyboards - far nicer than my many other Key Tronic foam and foil keyboards. After the pad replacement, it felt like my least favourite Key Tronic foam and foil keyboard - too stiff. Possibly, the light & smooth feel that I liked was because the pads were degraded and it was never really that nice - or the replacement pads were slightly too thick for this keyboard, making resistance too great. Or maybe I tightened the keyboard screws too tight. Who knows?

I don't want to say anything bad about the TexElec pads because I think it's a great service they provide at a reasonable cost, helping restore many vintage keyboards that would otherwise be a pain in the ass to restore. Possibly there were variations in foam thickness for different keyboards of that era.

- Sangdrax

- Location: Hill Country

- Main keyboard: Harris 1978 Terminal

- Main mouse: Mammoth

- DT Pro Member: -

Different switch types probably had different thicknesses. The 1978 block style keytronic I'm working on right now seems like it had around 2mm pads instead of the 4'ish of the 1980's tall single switch models.

- mmm

- Location: Denmark

- Main keyboard: 34-key split keyboard / F122

- Main mouse: Mx Ergo / Trackpad

- Favorite switch: Cap bs

Necroposting!

I'm attempting to find some low density foam for a restoration. I am not sure where to start looking. It seems I am able to find low density polyurethane foam sold as "speaker grill foam", "fish tank sponge*, *carbon filter sponge* and the likes on aliexpress, which is currently my best bet (only sold as 3mm or too thick). Any other suggestions on where to possibly look? Alternative products? I'm located in Denmark, so I don't have access to the brands mentioned in this thread, but I won't mind waiting for quite a bit for it to arrive as long as VAT is prepaid

I currently have a ~78 with (supposedly) Texelec pads, which I find a too tall and dense, and a ~82 with out-of-date foam. Admittedly I have not tried the Texelec pads in my ~82 yet, but I suspect that I will find the dampening too intense here too, though better.

I'm attempting to find some low density foam for a restoration. I am not sure where to start looking. It seems I am able to find low density polyurethane foam sold as "speaker grill foam", "fish tank sponge*, *carbon filter sponge* and the likes on aliexpress, which is currently my best bet (only sold as 3mm or too thick). Any other suggestions on where to possibly look? Alternative products? I'm located in Denmark, so I don't have access to the brands mentioned in this thread, but I won't mind waiting for quite a bit for it to arrive as long as VAT is prepaid

I currently have a ~78 with (supposedly) Texelec pads, which I find a too tall and dense, and a ~82 with out-of-date foam. Admittedly I have not tried the Texelec pads in my ~82 yet, but I suspect that I will find the dampening too intense here too, though better.

-

xxhellfirexx

- Location: Canada

- DT Pro Member: -

- mmm

- Location: Denmark

- Main keyboard: 34-key split keyboard / F122

- Main mouse: Mx Ergo / Trackpad

- Favorite switch: Cap bs

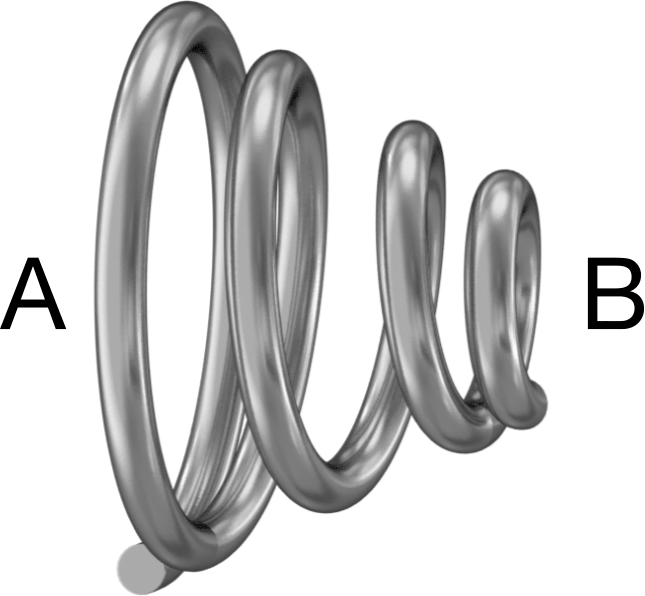

Thanks for the suggestion. My guess would be that these would also be too dense compared to what I am looking for. I am basing this by the look of the skin displacement to foam compression relationship in this image, and that the foam looks dense, there is a chance I'm wrong, but 40 euros shipped is a lot for something I'm not confident about. I will probably end up ordering a few different kinds of foam to experiment with, and cross my fingers that I will be able to accurately cut slices in accurate sizes.xxhellfirexx wrote: ↑30 Mar 2022, 19:10Would these work for you?

https://www.ebay.com/itm/274555743649

Spoiler:

-

Jan Pospisil

- Location: Czech Republic

- Main keyboard: BTC 5169

- Main mouse: CZC GM600

- Contact:

A possibly incredibly stupid question - has anyone tried replacing the foam with a very short spring?

- jsheradin

- Location: USA

Sourcing springs with sane weighting might be difficult and would probably need a GB. That diameter and length are only mass produced in wave and conical springs from what I know. I bet the capsense mechanism would still work if the foam pads were replaced entirely by a topre like spring and the PCB covered in kapton tape. The metal of the spring would be enough that you don't need mylar but sensing too early might be an issue.Jan Pospisil wrote: ↑01 Apr 2022, 16:29A possibly incredibly stupid question - has anyone tried replacing the foam with a very short spring?

Spoiler:

-

Jan Pospisil

- Location: Czech Republic

- Main keyboard: BTC 5169

- Main mouse: CZC GM600

- Contact:

Right, I don't suppose you could just buy Topre springs, but maybe Niz could be persuaded to sell them separately?

- mmm

- Location: Denmark

- Main keyboard: 34-key split keyboard / F122

- Main mouse: Mx Ergo / Trackpad

- Favorite switch: Cap bs

I've also considered whether it would be possible to replace it with a spring.

I haven't considered conical. Would you then mount the conical spring directly to the PCB instead? I'm a little concerned, whether a spring would reverberate too much, and cause faulty keypresses this way. Topre overcomes this, by having the dome double as a dampener for the spring. And most compression springs in other switches are compressed, even when they are as extended as they can be, making the slider stay put when there are spring reverberations. The foam pad (I guess this is also a compression spring) has built in dampening to overcome this.

The wavy spring seems super cool to make a drop-in replacement if it was available in a light enough weight.

But to come back to the conical spring. Would a conical spring that is slightly compressed when the switch is resting work out, if the sense level is set in a way, that it will actuate when the switch reaches a given position? Or am I just science fictioning capsense?

I haven't considered conical. Would you then mount the conical spring directly to the PCB instead? I'm a little concerned, whether a spring would reverberate too much, and cause faulty keypresses this way. Topre overcomes this, by having the dome double as a dampener for the spring. And most compression springs in other switches are compressed, even when they are as extended as they can be, making the slider stay put when there are spring reverberations. The foam pad (I guess this is also a compression spring) has built in dampening to overcome this.

The wavy spring seems super cool to make a drop-in replacement if it was available in a light enough weight.

But to come back to the conical spring. Would a conical spring that is slightly compressed when the switch is resting work out, if the sense level is set in a way, that it will actuate when the switch reaches a given position? Or am I just science fictioning capsense?

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Capsense is analogue, remember. The exact transition point isn’t nearly as twitchy as contact switches, which have no other context to provide. With capsense, the signal increases and increases until, oh look there it gone did it, it increases some more. Spring shake just isn’t going to be an issue on analogue.

- mmm

- Location: Denmark

- Main keyboard: 34-key split keyboard / F122

- Main mouse: Mx Ergo / Trackpad

- Favorite switch: Cap bs

This is not spring shake, this is spring bounce! I'm talking about a case where the spring is not in contact with the slider in resting position. When the spring is fully compressed, and the slider is released (the external coilspring accelerating the slider upwards), then the internal conical compression spring will accelerate towards its resting position, but then accelerate even further and extend slightly, which makes it accelerate back towards the resting position, and then possibly back to the point of actuating again! There is a good chance I may be overestimating how much switch bounce will occur, I just wanted it to be a consideration. Or if this process will be fast enough for it to be negligible and the software will just think the extra touch of actuation point is the user holding the button down a bit longer.Muirium wrote: ↑03 Apr 2022, 12:21Capsense is analogue, remember. The exact transition point isn’t nearly as twitchy as contact switches, which have no other context to provide. With capsense, the signal increases and increases until, oh look there it gone did it, it increases some more. Spring shake just isn’t going to be an issue on analogue.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Digital thinking again. Capsense has context. The controller isn't faced with an inscrutable instantaneous 1 or 0, bedevilled by contact noise. It's a nice multi-digit variable for every key, like this:

Think of it like this: it's much easier to identify and discard the proverbial "straw that broke the camel's back" when you can see the camel.

Now the controller makers among us can explain how it really works, but my nontechnical understanding is that debouncing isn't a practical problem on capsense, and that's because of the greater signal bandwidth you get from the now analogue "switch". Each key can have its own threshold value. How they calibrate that precisely, they can explain. But what I've found with Pandrew's controller is an excellent Topre-level freedom from chatttttery bbbollocks. Debouncing (inherently dirty and digital) contact switches is an art: needing delayed logic to establish signal to noise threshold, letting time smooth the transition out instead; at the cost of response speed. Determining actuation on analogue switches is more a matter of just letting them speak for themselves.

- mmm

- Location: Denmark

- Main keyboard: 34-key split keyboard / F122

- Main mouse: Mx Ergo / Trackpad

- Favorite switch: Cap bs

Thanks for the explanation, but this is a bit different - this is bounce, not an issue elsewhere, I think! I may be overapproximating the amplitude and underapproximating the frequency and dampening. Here is a video demonstration of a spring bouncing at a low frequency with low dampening and a significant amplitude. The case I'm talking about is of course significantly different, and there are no weight at the end of the spring, making the whole case less extreme.

For debounce in cap BS, the frequency is of significantly higher frequency, and there are forces that both keep the flipper attached, and forces that make sure, that the flipper cannot return back to the capacitive pad after the key has returned.

Debbouncee isssuee

Boubncen isisusueue

(may also present itself as the key being held down too long, with higher frequencies)

If we imagine that the slider is immediately released, then the spring will be free to bounce within the "bounce interval". If the spring dampening has little enough dampening, then the spring will first extend, and then return to the actuation point again, after the key has been released. If the frequency is 5 Hz, that means that the spring will return to the actuation point 200ms after the key that has been released, giving the software no possibility of knowing whether it's a keypress or bounce, as it may have been two successive presses, but also bounce, since the pcb has no way of measuring the slider position in this case.

This was only meant as a brief side-comment, and there are multiple ways to counter this issue:

For debounce in cap BS, the frequency is of significantly higher frequency, and there are forces that both keep the flipper attached, and forces that make sure, that the flipper cannot return back to the capacitive pad after the key has returned.

Debbouncee isssuee

Boubncen isisusueue

(may also present itself as the key being held down too long, with higher frequencies)

If we imagine that the slider is immediately released, then the spring will be free to bounce within the "bounce interval". If the spring dampening has little enough dampening, then the spring will first extend, and then return to the actuation point again, after the key has been released. If the frequency is 5 Hz, that means that the spring will return to the actuation point 200ms after the key that has been released, giving the software no possibility of knowing whether it's a keypress or bounce, as it may have been two successive presses, but also bounce, since the pcb has no way of measuring the slider position in this case.

This was only meant as a brief side-comment, and there are multiple ways to counter this issue:

- If the dampening is high enough this will not be an issue at all

- Having the spring be compressed in resting position (like virtually every switch)

- Having some kind of overextention-limit, just like topre

- Have additional dampening

- TNT

- Location: Germany, Karlsruhe

- Main keyboard: Ellipse Model F77 / Zenith Z-150

- Main mouse: Logitech G203 Prodigy

- Favorite switch: It's complicated

- DT Pro Member: 0250

I've replaced mine with those Texelec Pads and kinda like them. But a conversion like this sounds interesting, to say the least.

Since I don't want to face prison time for committing a major offense, here's my picture with a little nod to the original:

Since I don't want to face prison time for committing a major offense, here's my picture with a little nod to the original:

-

Jan Pospisil

- Location: Czech Republic

- Main keyboard: BTC 5169

- Main mouse: CZC GM600

- Contact:

They really are quite handsome keyboards.