I am a bit afraid of the complexity of the contact plate. I am not sure if it can be reproduced on a semi-industrial scale. On the other hand, it would probably be easy to reproduce the skcm top/bottom housings and the slider. Maybe it is worth to start there and see how far we can get.

Recreating the Lisp keyboard (10 years later)

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

- Mandarbmax

- Location: USA

- Main keyboard: Unicomp Classic

- Main mouse: Steel Series Sensei Raw

- Favorite switch: Buckling Springs

I wish to chime in in support of Inozenz and say that I would also love to see you make you own Alps clone switch. Maybe you could even reuse Matias parts for most of it and just replace the switchplate and perhaps the click leaf too? I bet there would be a market for after market click leaves and switchplates in the same way that there is a market for SPRiT spring! Either way lispnick, you are an inspiration to us all.

- depletedvespene

- Location: Chile

- Main keyboard: IBM Model F122

- Main mouse: Logitech G700s

- Favorite switch: buckling spring

- DT Pro Member: 0224

- Contact:

Jaw, meet flooor. Impressive, impressive, IMPRESSIVE.lispnick wrote: 11 Jun 2021, 00:25 Finally, I got the time to make video on making a keycap! I have been asked to make a custom ESC key based on an SVG graphics. I took this as an opportunity to make video of the whole process. Here it is:

- depletedvespene

- Location: Chile

- Main keyboard: IBM Model F122

- Main mouse: Logitech G700s

- Favorite switch: buckling spring

- DT Pro Member: 0224

- Contact:

Just out of sheer lack of shame, I'll say "lispnick, I hope you brought enough for everybody!"

Also, might keycaps for SKCC switches be beyond the factibility of your process? Asking for a... uhhhh... friend?

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

With the present technology, it means reworking at least half of all the moulds, … so it depends on the depth of your pocket.depletedvespene wrote: 26 Aug 2021, 20:52Just out of sheer lack of shame, I'll say "lispnick, I hope you brought enough for everybody!"

Also, might keycaps for SKCC switches be beyond the factibility of your process? Asking for a... uhhhh... friend?

- daedalus

- Buckler Of Springs

- Location: Ireland

- Main keyboard: Model M SSK (home) HHKB Pro 2 (work)

- Main mouse: CST Lasertrack, Logitech MX Master

- Favorite switch: Buckling Spring, Beam Spring

- DT Pro Member: 0087

Awesome project. Any plans to do non blank modifier keys with the same legends as the Symbolics keycaps?

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

Yes, I am working on it. I hope to do more than that but I would like to use a slightly different process. Takes more tests to be sure it can be done. Anyway, for those who have my blank modifiers, I will offer a reasonably priced upgrade to keys with legends.daedalus wrote: 29 Aug 2021, 01:42 Awesome project. Any plans to do non blank modifier keys with the same legends as the Symbolics keycaps?

- Mandarbmax

- Location: USA

- Main keyboard: Unicomp Classic

- Main mouse: Steel Series Sensei Raw

- Favorite switch: Buckling Springs

I bet you that there would be good money in an MX mount set; goodness knows that I'd pay through the nose for a matching set with a big ass enter which would fit on my K151L!lispnick wrote: 28 Aug 2021, 20:14With the present technology, it means reworking at least half of all the moulds, … so it depends on the depth of your pocket.depletedvespene wrote: 26 Aug 2021, 20:52Just out of sheer lack of shame, I'll say "lispnick, I hope you brought enough for everybody!"

Also, might keycaps for SKCC switches be beyond the factibility of your process? Asking for a... uhhhh... friend?

Also, I do not have any SKCC switches to test it. But the good news is that I consider support of various keycap mounts in the future.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

Be careful what you wish for. You might get it.Mandarbmax wrote: 16 Sep 2021, 01:31I bet you that there would be good money in an MX mount set; goodness knows that I'd pay through the nose for a matching set with a big ass enter which would fit on my K151L!lispnick wrote: 28 Aug 2021, 20:14With the present technology, it means reworking at least half of all the moulds, … so it depends on the depth of your pocket.depletedvespene wrote: 26 Aug 2021, 20:52

Just out of sheer lack of shame, I'll say "lispnick, I hope you brought enough for everybody!"

Also, might keycaps for SKCC switches be beyond the factibility of your process? Asking for a... uhhhh... friend?

Also, I do not have any SKCC switches to test it. But the good news is that I consider support of various keycap mounts in the future.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

With the kind of manufacturing I run, I am afraid that I cannot get to the price tag of the classic injection-molded sets, however, I would like to offer more value for the price—more customization options including the support of various non-MX mounts.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Given this is DT: the non-MX mounts you're going to be asked about are Topre (doable), Alps (same) and IBM buckling spring (whole other story). Some cheeky buggers like me will even mention IBM beamspring, which is technically more feasible, but the cost of entry to those boards is $1k+. They're rare stuff.

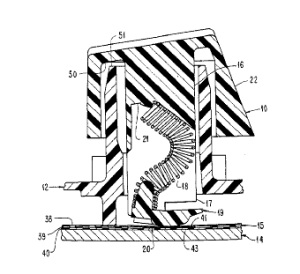

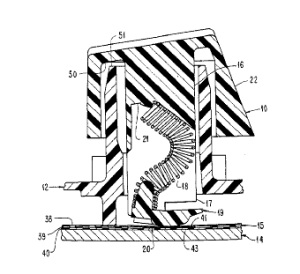

Buckling spring caps have to be hollow. The spring actually buckles inside of them, like this:

Doubleshot IBM buckling spring caps would be a holy grail, especially around here. Big technical challenge, though. Topre would be a wiser target. They also have limited caps availability—and no doubleshots—but with a much friendlier mount.

Buckling spring caps have to be hollow. The spring actually buckles inside of them, like this:

Doubleshot IBM buckling spring caps would be a holy grail, especially around here. Big technical challenge, though. Topre would be a wiser target. They also have limited caps availability—and no doubleshots—but with a much friendlier mount.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

I bet that with all the AZERTY NOS keyboards that appeared recently, there might be some interest in space invaders as well. I can imagine that some folks would like to make their own builds based on these.Muirium wrote: 26 Sep 2021, 00:02 Given this is DT: the non-MX mounts you're going to be asked about are Topre (doable), Alps (same) and IBM buckling spring (whole other story). Some cheeky buggers like me will even mention IBM beamspring, which is technically more feasible, but the cost of entry to those boards is $1k+. They're rare stuff.

Buckling spring caps have to be hollow. The spring actually buckles inside of them, like this:

Doubleshot IBM buckling spring caps would be a holy grail, especially around here. Big technical challenge, though. Topre would be a wiser target. They also have limited caps availability—and no doubleshots—but with a much friendlier mount.

The easiest way to go for buckling springs (from my perspective) is to make keycaps in a dedicated mono profile that is just a cover for Model M stems. By the way, I love this project and took a lot of inspiration from there. It would be great to revive it!

The keycaps for beamsprings are indeed easy. I have two beamspring keyboards to restore, one with a cracked case and a lot of keys missing, so it is in my own interest to make keycaps for it in the future.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Aha! I may be interested in a few red and green beamspring double shots myself then!

You’re right about buckling spring: “two-piece” uppers are all you need to address, on the alphas anyway. But those fellas clip onto their lower counterparts. I suspect a certain Goldilocks zone of flexibility is required to make them clip right.

You’re right about buckling spring: “two-piece” uppers are all you need to address, on the alphas anyway. But those fellas clip onto their lower counterparts. I suspect a certain Goldilocks zone of flexibility is required to make them clip right.

- TNT

- Location: Germany, Karlsruhe

- Main keyboard: Ellipse Model F77 / Zenith Z-150

- Main mouse: Logitech G203 Prodigy

- Favorite switch: It's complicated

- DT Pro Member: 0250

That's amazingmorbid42 wrote: 04 Oct 2021, 15:22 Wonder if I can purchas some of your awsome keycaps, cause I can made the whole keyboard except for the keycaps.

I'm all for that sleek Apple look, but Lispnick's caps surely would be an interesting combination

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

I initially did not want to sell just keycaps for several reasons but I got a lot of requests and I am now seriously considering it. I would like to use a slightly different approach that would give me more options and reduces the manufacturing time. I will probably open a separate thread about it later, so stay tuned!morbid42 wrote: 04 Oct 2021, 15:22 Wonder if I can purchas some of your awsome keycaps, cause I can made the whole keyboard except for the keycaps.

- TheInverseKey

- Location: Great White North

- Main mouse: M570

- Favorite switch: Hi-Tek 725 Linear

- DT Pro Member: 0216

- Contact:

Ohh wow, will stay glued to Spy for this.lispnick wrote: 04 Oct 2021, 17:39I initially did not want to sell just keycaps for several reasons but I got a lot of requests and I am now seriously considering it. I would like to use a slightly different approach that would give me more options and reduces the manufacturing time. I will probably open a separate thread about it later, so stay tuned!morbid42 wrote: 04 Oct 2021, 15:22 Wonder if I can purchas some of your awsome keycaps, cause I can made the whole keyboard except for the keycaps.

- morbid42

- Location: China

- Main keyboard: Homemade keyboards

- Favorite switch: Alps SKCM/SKCL, FLS, buckling spring, Hi-tek 725

that would be awsome!lispnick wrote: 04 Oct 2021, 17:39I initially did not want to sell just keycaps for several reasons but I got a lot of requests and I am now seriously considering it. I would like to use a slightly different approach that would give me more options and reduces the manufacturing time. I will probably open a separate thread about it later, so stay tuned!morbid42 wrote: 04 Oct 2021, 15:22 Wonder if I can purchas some of your awsome keycaps, cause I can made the whole keyboard except for the keycaps.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

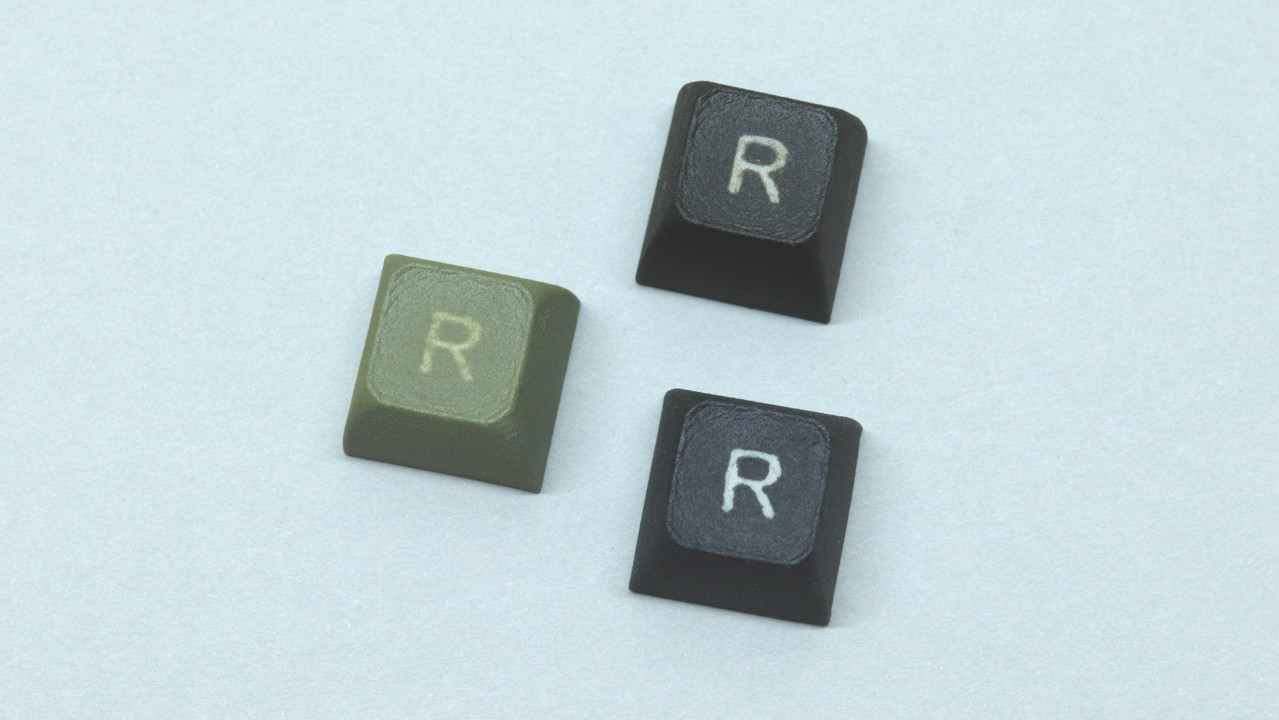

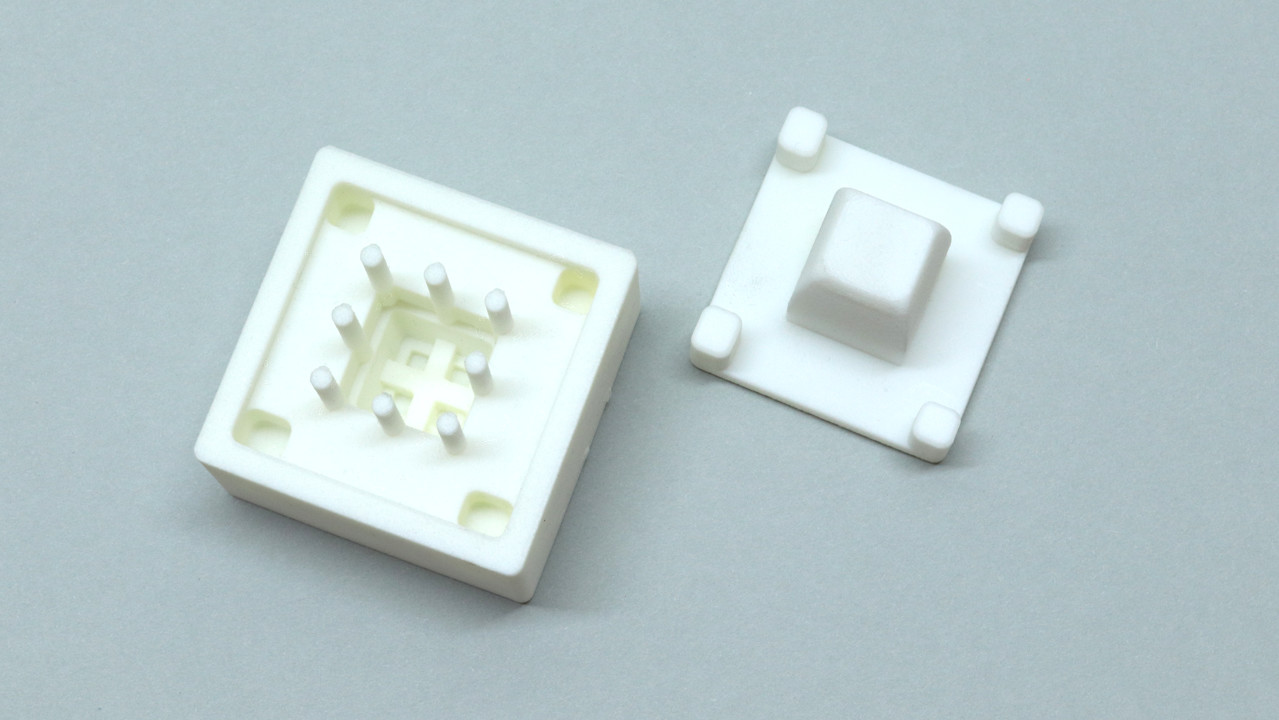

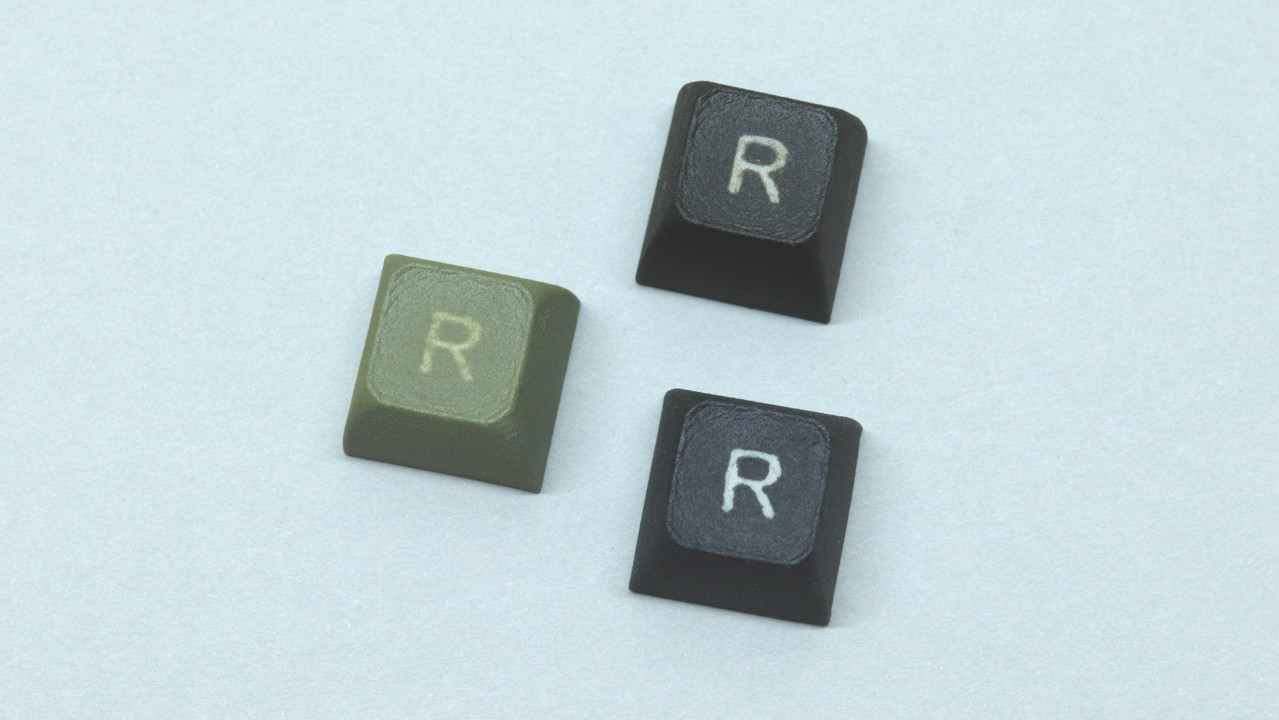

I got some interesting comments for my keycap manufacturing video. A lot of people suggested to use a 3d printer for the keycaps. Actually, I did some experiments with 3d printing in the early prototyping phase. My first idea was to use resin casting in conjunction with 3d printing and I made several 3d-printed bases to make the moulds. Also, I have experimented with 3d-printed inserts. The results looked like this:

Definitely usable but the surface was too rough. Also, the edges of the inserts were not sharp enough so the letters look fuzzy. Interestingly, the keycap on the left was originally in French blue. The pigment was not UV-stable and now it looks like something forgotten at a public men's room.

The original bases were 3d-printed from Nylon on a commercial-grade 60-micron SLS printer and it has been a few years ago. I think that with the modern SLA printers with monochrome displays one can get better results but I am not sure if such printers are a good choice for making bases because the printed models are usually brittle (removing the cured silicone from the base requires some force).

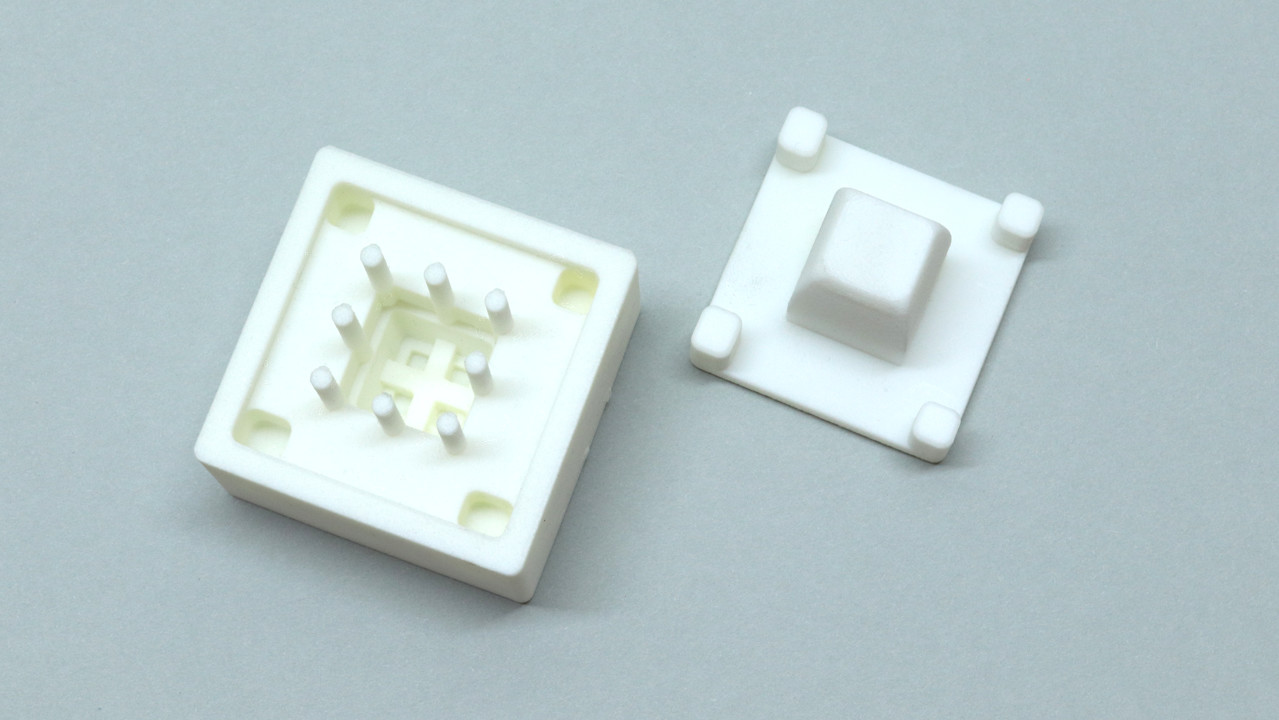

My initial bases were inspired by the :~$YNTH system:

The next logical step was to abandon the 3d printed bases and use machined bases . At this point I still thought that the 3d-printed inserts were the way to go. This was definitely an improvement—the surface of the keycaps was smooth but the legend was still fuzzy:

The trouble with 3d-printed inserts is that the legend was not aligned with the top of the keycap dish because of the printing precision and material properties. Since the polyurethane precursors have a very low viscosity, the material has a tendency to fill all the tiny holes that result from the misalignment, hence the fuzzy edges.

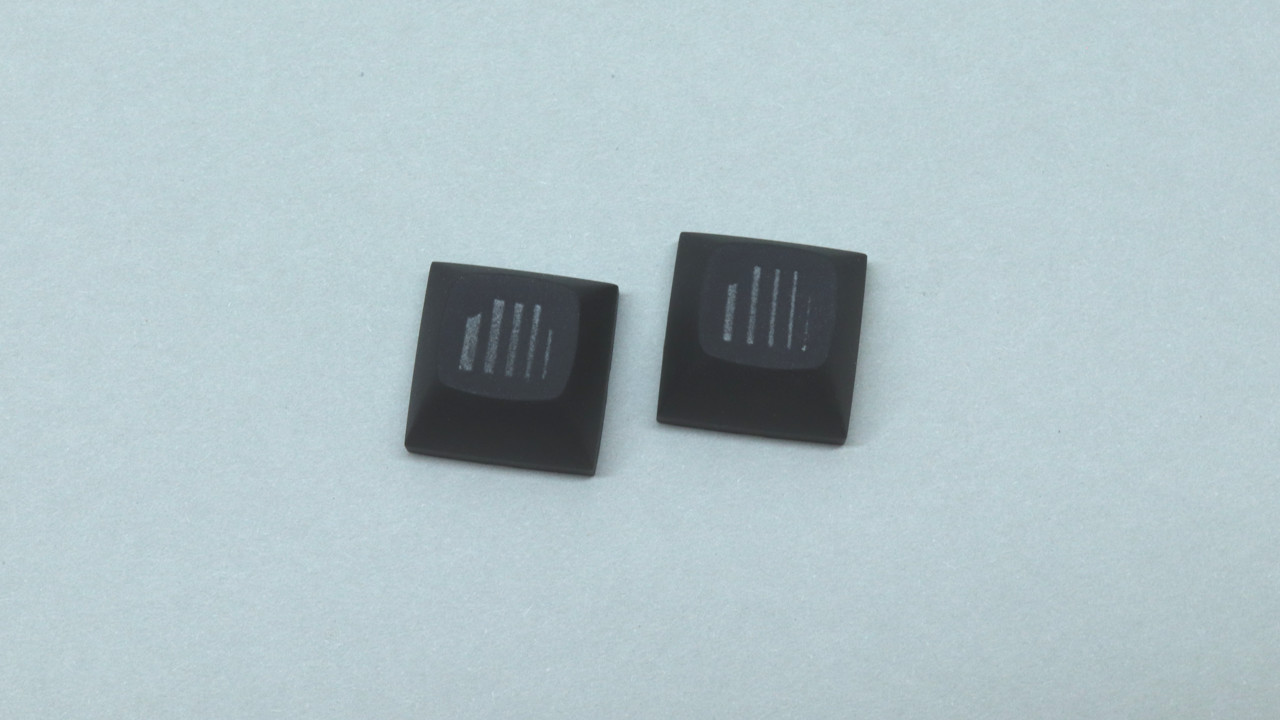

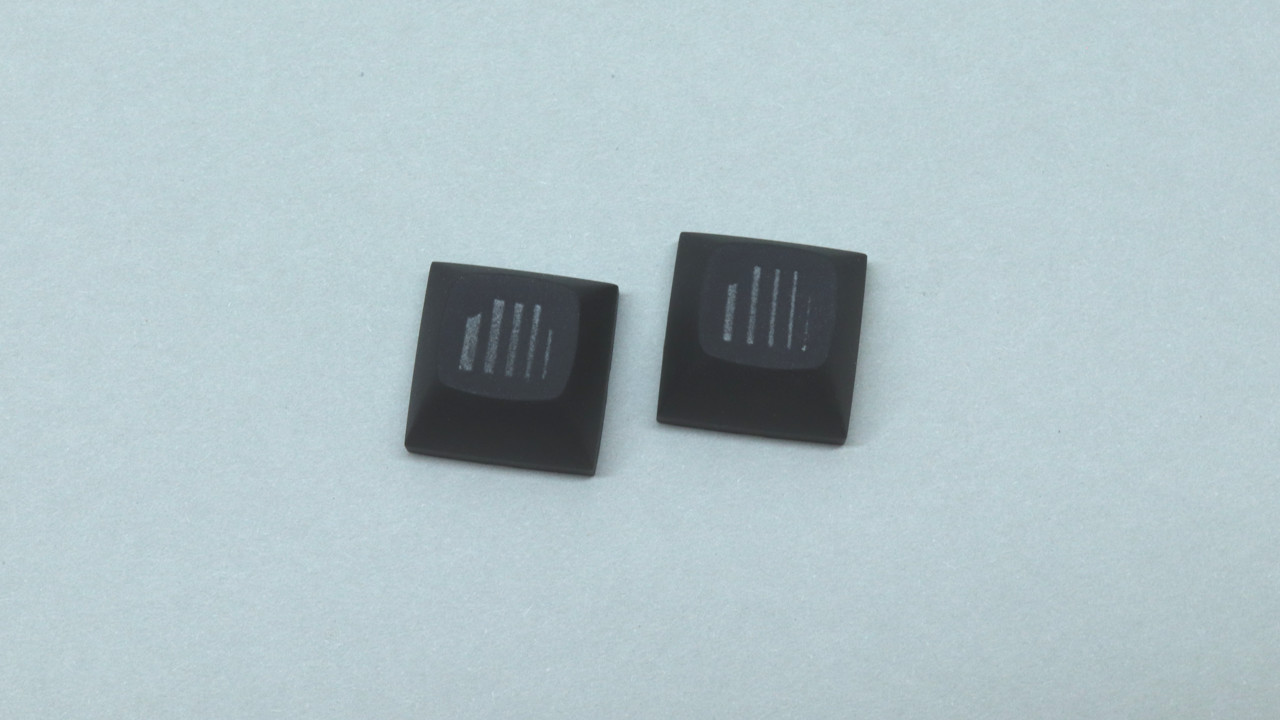

Another trouble with 3d printers in general is the part orientation. Depending on the machine and material, orientation of the insert in the printer may have a drastic impact of the sharpness and thickness of the edges. For instance:

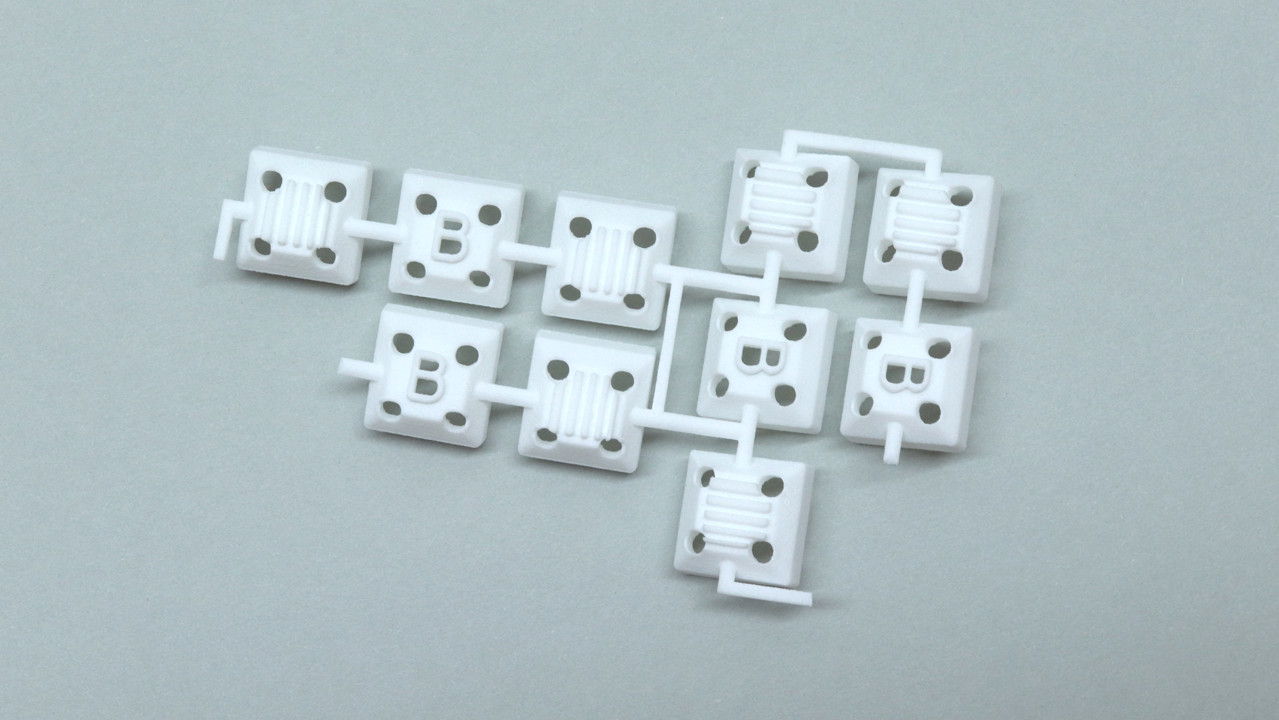

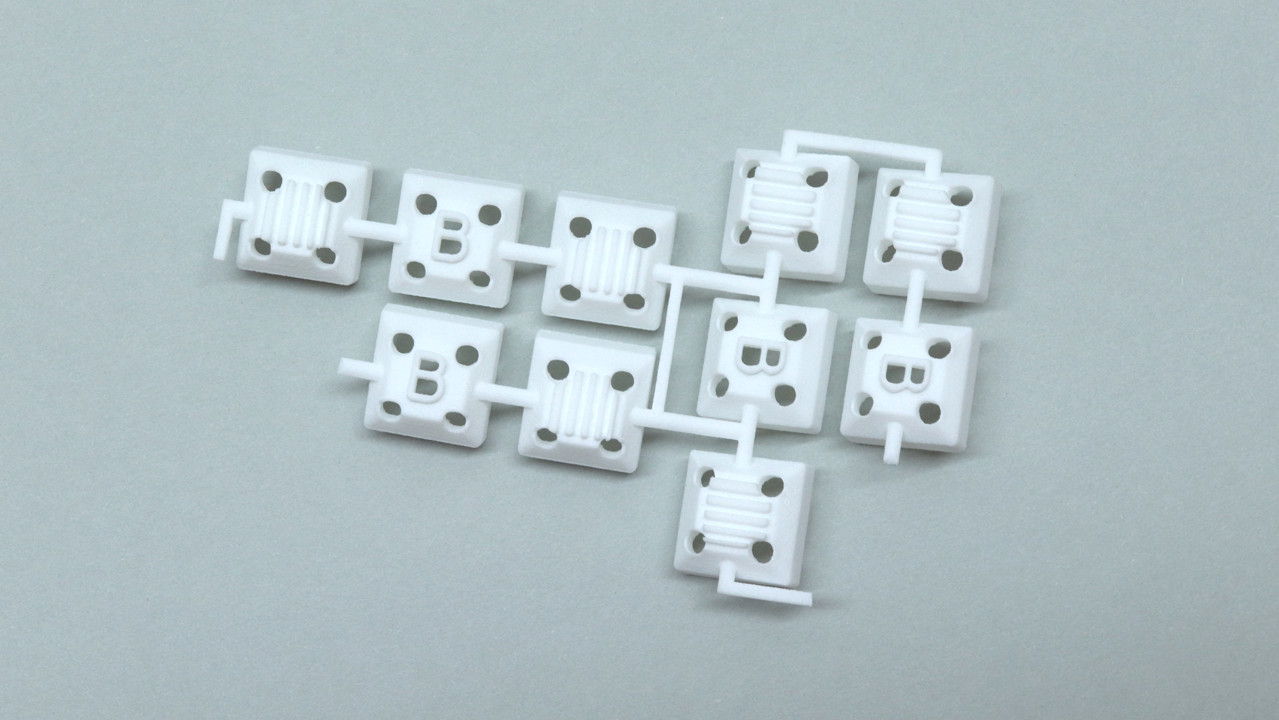

These two were created using the same insert that I made to test the line thickness. The lines on the left are thicker even though the insert model is the same as in the previous case. It actually came from the following insert set that was all printed at once:

Not much later after these experiments I came with the idea of machining the legend bases from polyurethane copies of the original bases. This in theory ensures the best alignment with the keycap dishes and is closer to the classic two-shot moulding.

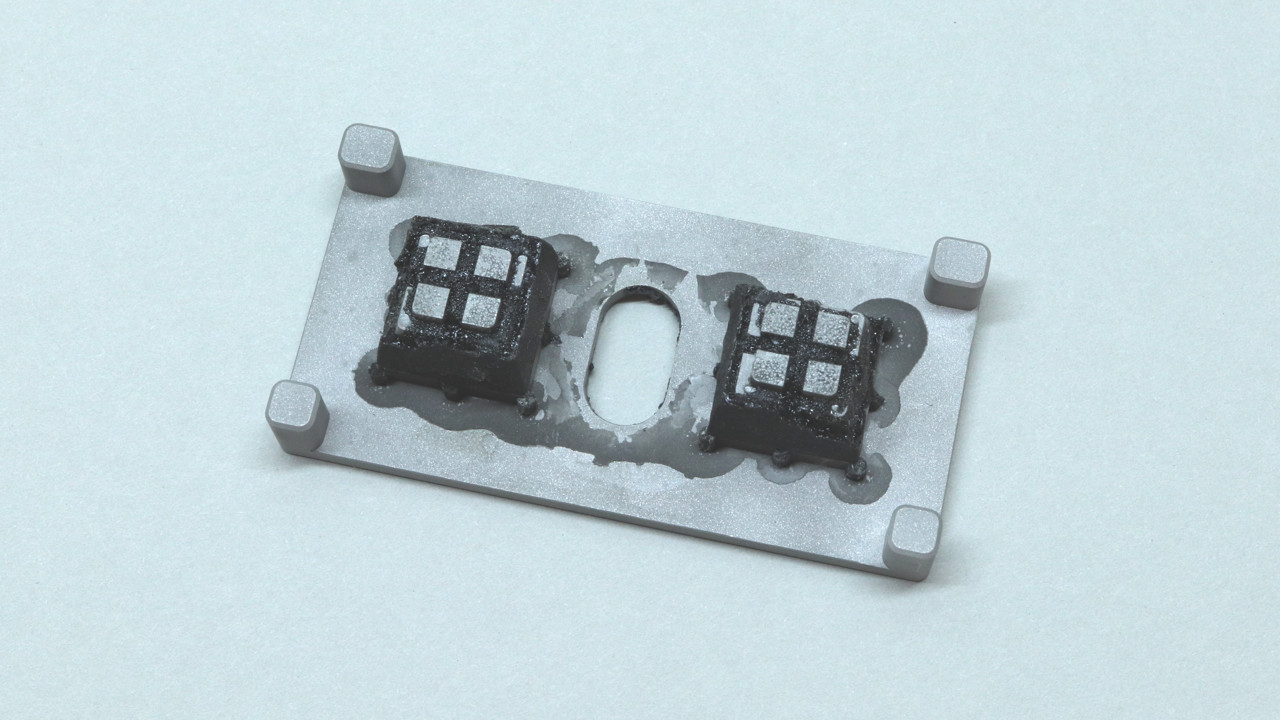

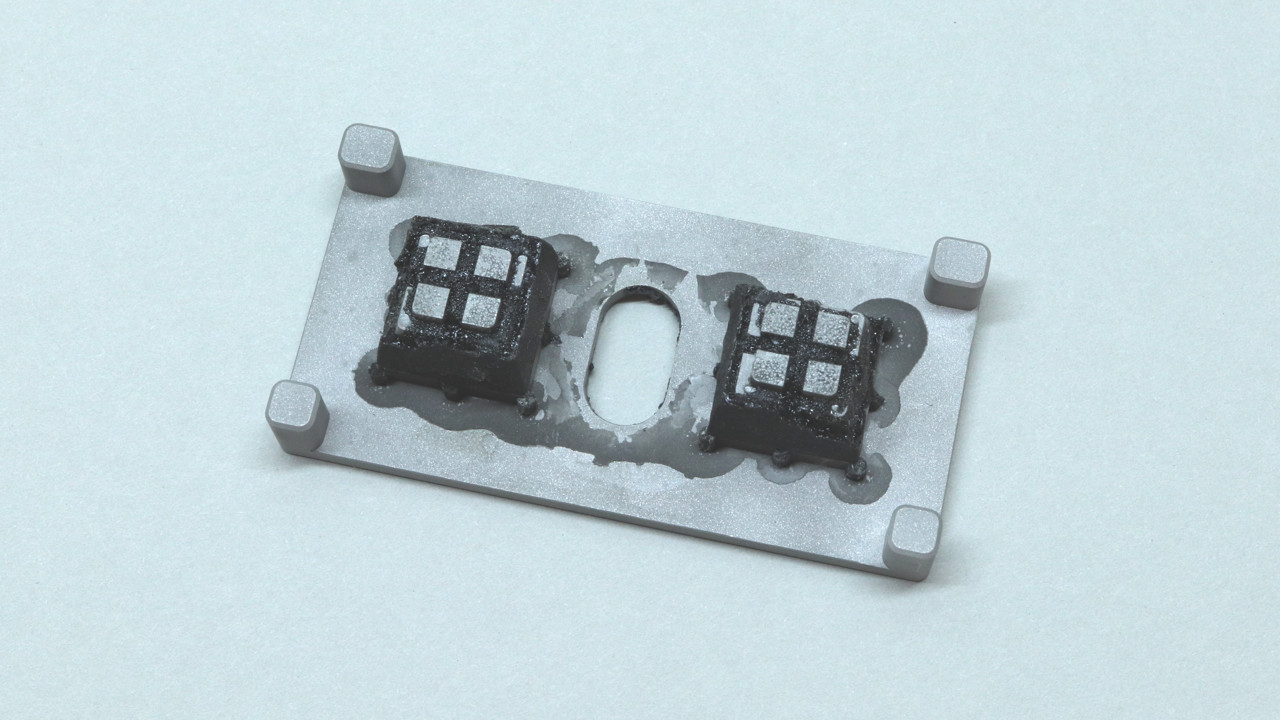

Finally, one more photo from the tough beginnings:

Yes, polyurethane does stick to untreated aluminium. There went my 250€ investment.

Definitely usable but the surface was too rough. Also, the edges of the inserts were not sharp enough so the letters look fuzzy. Interestingly, the keycap on the left was originally in French blue. The pigment was not UV-stable and now it looks like something forgotten at a public men's room.

The original bases were 3d-printed from Nylon on a commercial-grade 60-micron SLS printer and it has been a few years ago. I think that with the modern SLA printers with monochrome displays one can get better results but I am not sure if such printers are a good choice for making bases because the printed models are usually brittle (removing the cured silicone from the base requires some force).

My initial bases were inspired by the :~$YNTH system:

The next logical step was to abandon the 3d printed bases and use machined bases . At this point I still thought that the 3d-printed inserts were the way to go. This was definitely an improvement—the surface of the keycaps was smooth but the legend was still fuzzy:

The trouble with 3d-printed inserts is that the legend was not aligned with the top of the keycap dish because of the printing precision and material properties. Since the polyurethane precursors have a very low viscosity, the material has a tendency to fill all the tiny holes that result from the misalignment, hence the fuzzy edges.

Another trouble with 3d printers in general is the part orientation. Depending on the machine and material, orientation of the insert in the printer may have a drastic impact of the sharpness and thickness of the edges. For instance:

These two were created using the same insert that I made to test the line thickness. The lines on the left are thicker even though the insert model is the same as in the previous case. It actually came from the following insert set that was all printed at once:

Not much later after these experiments I came with the idea of machining the legend bases from polyurethane copies of the original bases. This in theory ensures the best alignment with the keycap dishes and is closer to the classic two-shot moulding.

Finally, one more photo from the tough beginnings:

Yes, polyurethane does stick to untreated aluminium. There went my 250€ investment.

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

New manufacturing video:

- depletedvespene

- Location: Chile

- Main keyboard: IBM Model F122

- Main mouse: Logitech G700s

- Favorite switch: buckling spring

- DT Pro Member: 0224

- Contact:

FASCINATING. Thanks for sharing these videos.

- Lalaland124

- Main keyboard: 3278

- Favorite switch: Beamspring

I could watch this all day

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

Recently, I have made some beefy stepped keys to replace two 1U keys. This idea came to me when I was asked if I can make the layout more ‘normal’. I did not want to tamper with the mount plate nor the PCB, so making a twin-stem 2U key that occupies the place of two adjacent 1U keys seemed to be the solution. The keys are stepped, of course, because there is no stabilizer wire and an ordinary 2U key would bind when pressed on the edges. The following video shows, among other things, how I make a base for a new keycap. For simplicity, I have used polyurethane instead of aluminium. One step in the video is missing—the bead blasting of the base (the video footage did not turn well).

- lispnick

- Location: Czechia

- Main keyboard: Keymacs A620N-88 Rev. A

- Main mouse: Kensington SlimBlade Trackball

- Favorite switch: Alps SKCM Orange

- Contact:

Spot the difference:

Detail of the classic bottom-right corner:

Stepped cursor keys:

… and how they are made:

Detail of the classic bottom-right corner:

Stepped cursor keys:

… and how they are made:

-

NewAlpsFan2

- Location: United States

Any updates on potentially selling the keycaps on their own? They're stunning