I guess I did contradict myself between the two posts. It all depends on the situation I suppose. What I'm trying to say is if the scratchy feeling is going to follow anything, it seems to follow the stems once they are damaged. Once a stem is scratchy, it seems to be scratchy in its original barrel, always. Moving it to another barrel is SOMETIMES scratchy, sometimes not. Moving a "fresh" stem into a previously scratchy barrel never seems to be scratchy. (after I wrote the rest of this post, it makes even more sense).

I'm unclear on the intent of why the keys need to be washed. Is this to wash off possible debris that you think may be causing the issue, to wash off the dry lube, or just that you don't want someone's "dirty" key caps back? There are only 10 keycaps on the board with dry lube applied, most of which are from the icon set anyway. I'd rather take the time to wash not wash every other keycap on the board if I don't have to. I'm not trying to be argumentative, I'm just not sure what we're getting at here.

I checked the springs and the end of the springs point towards the top of the keyboard.

All that being said though I think this is all a moot point after discovering some more information.

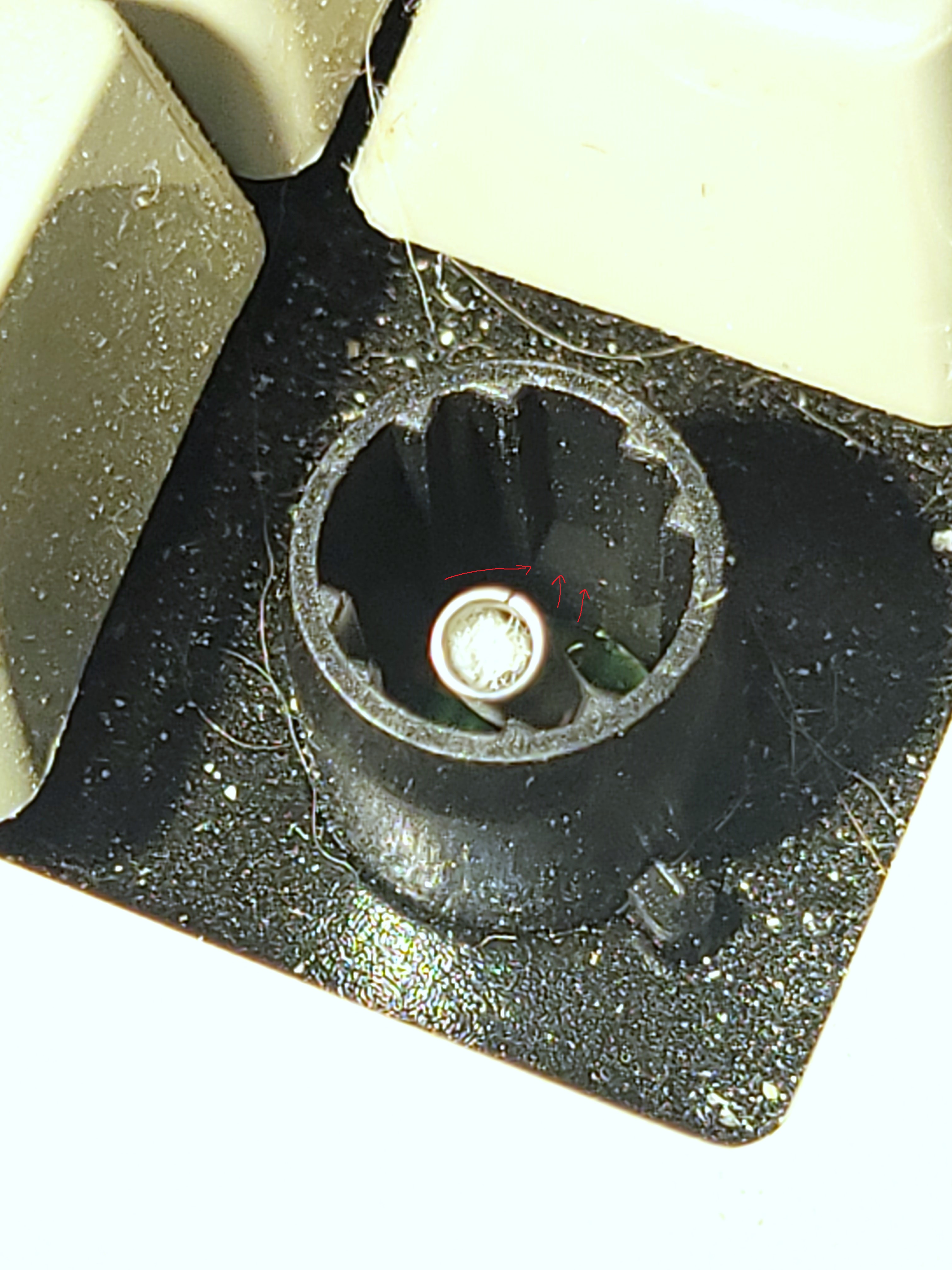

Because the mechanism is impossible to see once it is in the keyboard, I pulled out a spare barrel from the first aid kit to line up the wear pattern on the stem with the position on the barrel, and I think I am almost positive now as to what is causing the wear. There is a burr inside the bottom of the barrel damaging the stems.

The wear pattern on the stems aligns precisely with the "rim" of where the barrel meets into the bottom ~1mm thick part just before it opens up to the area where the flipper goes. You can see it (and feel it) from the underside easier.

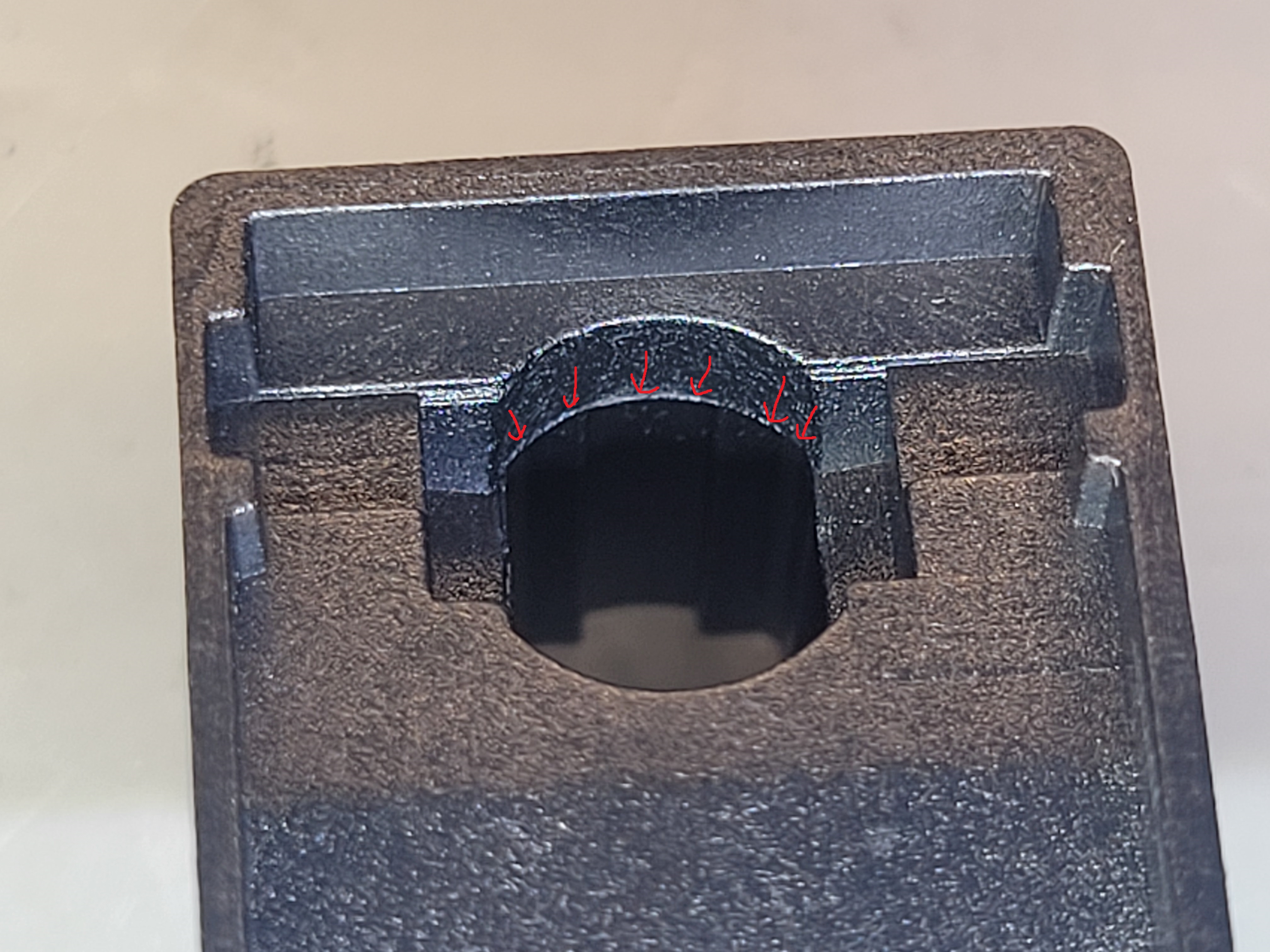

- 20250208_180301.jpg (1.62 MiB) Viewed 11264 times

There is an ever ever so slight ridge/burr protruding out. To the naked eye it looks like a sharp edge, but with the tip of a needle or screwdriver, you can feel the fine point catch on the burr. When the stem is pressed slightly skewed in the barrel, it rubs against this protruding ridge and this is what causes the wear on the parts that touch, the corner.

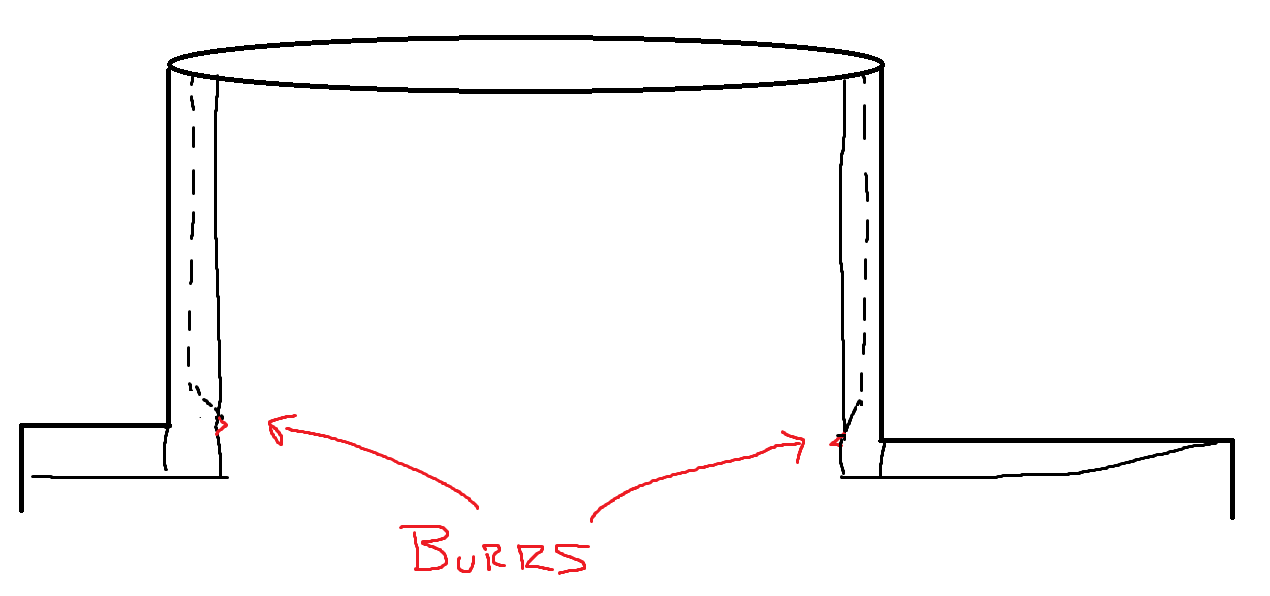

To try to draw a diagram of it, it would look something like this:

- burr on barrel.png (13.75 KiB) Viewed 11264 times

This correlates with what I'm seeing inside my F104 barrels, you can see right along that that ridge looks even more white, with what looks like worn stem material around it.

- 20250208_175752.jpg (3.76 MiB) Viewed 11264 times

If anything needs to be deburred, it would be the barrel itself, but that is impossible without removing every single barrel and doing something with that edge.

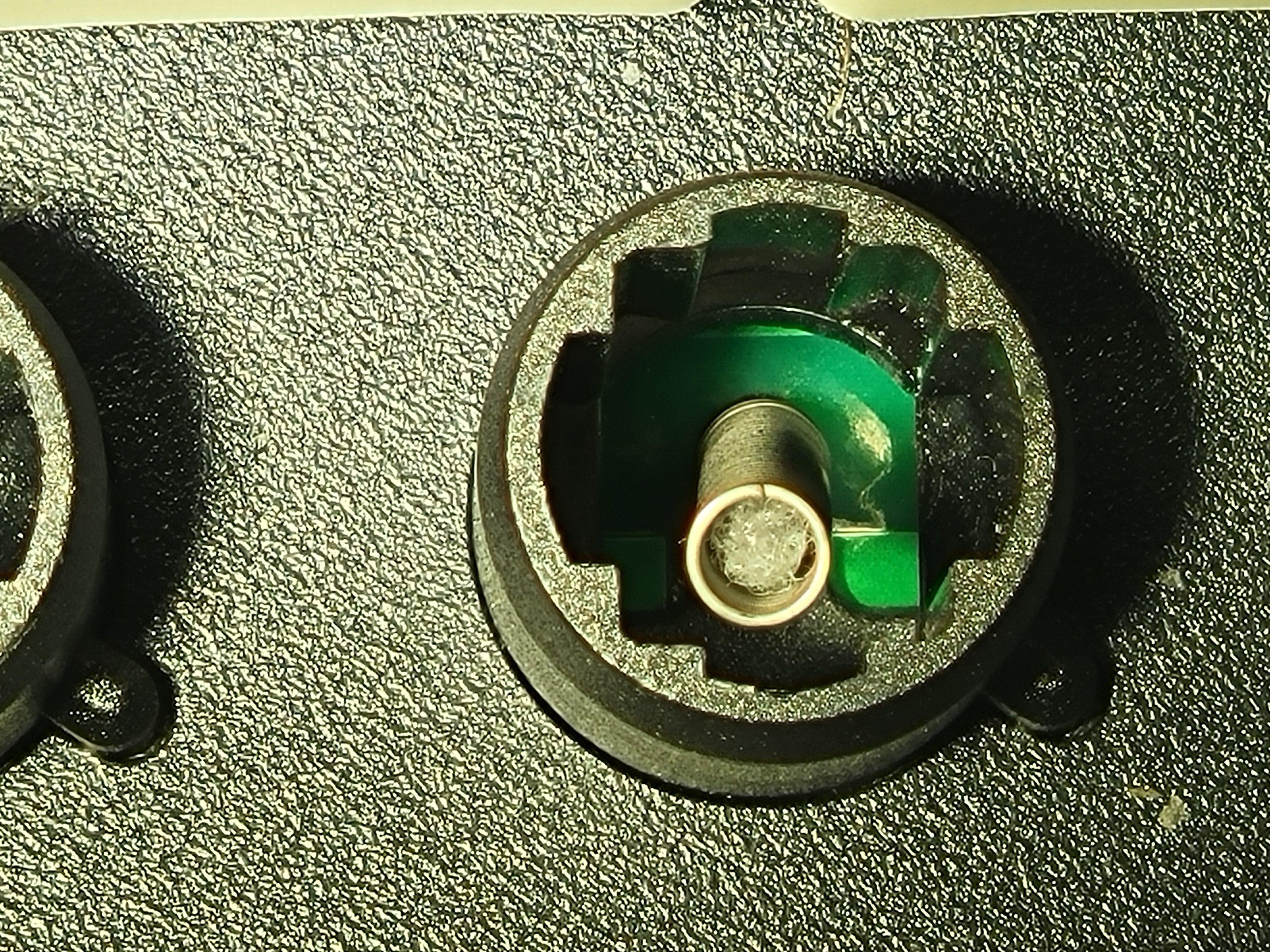

Take a look at the original IBM F122 barrel, that burr is not there. The shape is the same, the barrel goes down, there is a bevel, and then it goes straight down again to the bottom of the barrel, but the transition is perfectly smooth with no burrs.

- 20250208_183651.jpg (1.43 MiB) Viewed 11264 times

Pull out a few new barrels and compare them against any old Model Fs you may have. Check and feel that edge, I bet you'll find that it is there on the newly manufactured parts.

To me this seems to be a pretty definitive explanation to what is going on here. The burr on the harder fiberglass reinforced barrels (or whatever they are) is scraping against the softer PBT causing the scratchiness and wear. If the barrels are damaging the stems, that also explains why replacing replacing the keys just causes the problem to come back over time. It also explains why the "scratchy stems" that have been damaged don't "scratch" in the IBM barrels, because that burr isn't there for them to rub on.

Only you know exactly how the factory manufactures those barrels, but I would take a close look at whatever tooling or process determines what how the bottom edge of the barrel is manufactured and see if something can be done about it. The end result is definitely different than the way the original IBM part though.