Costar Stabilizer Inserts

- SL89

- ‽

- Location: Massachusetts, USA

- Main keyboard: CODE 104

- Main mouse: Logitech M570

- Favorite switch: Cherry MX Green

- DT Pro Member: 0095

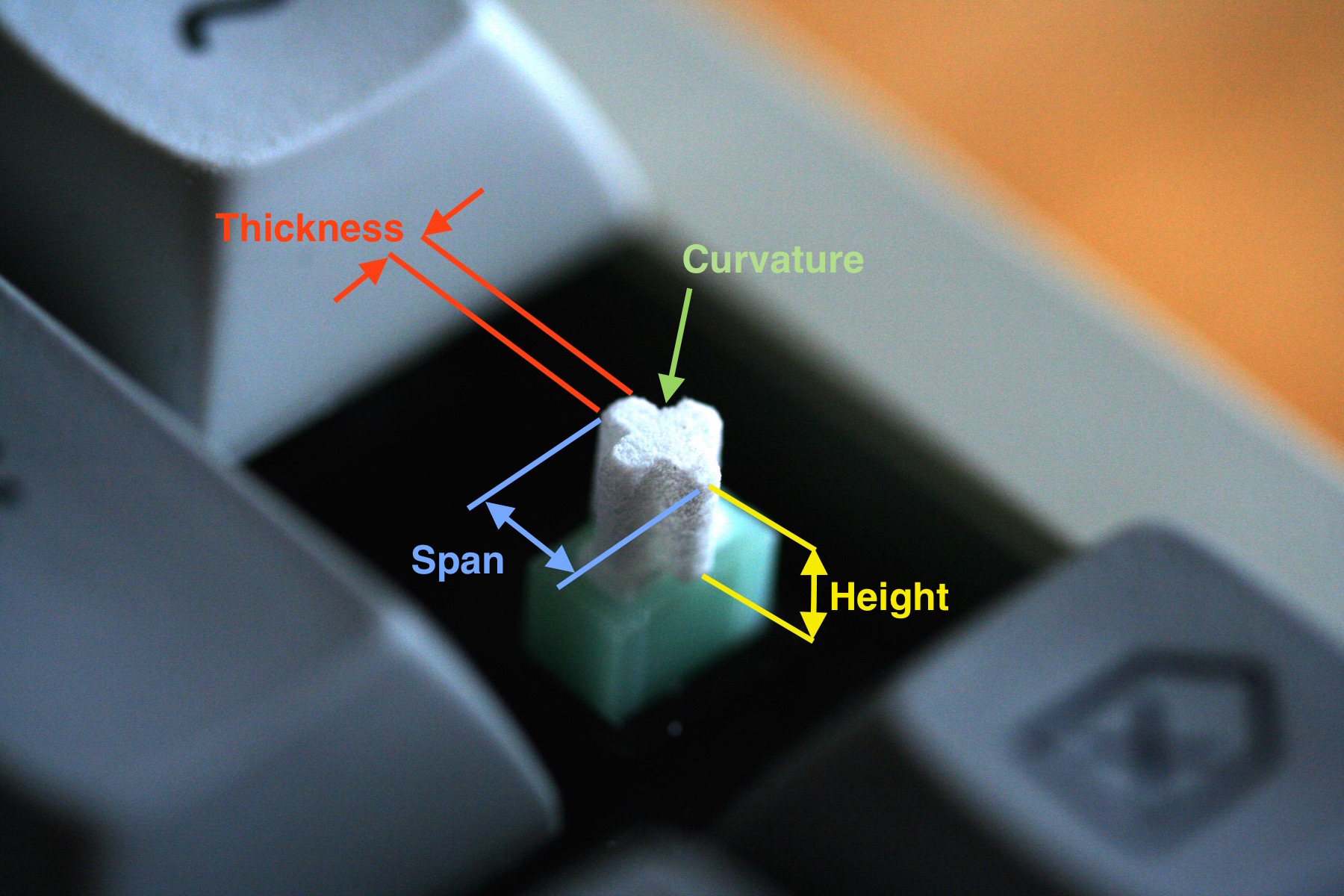

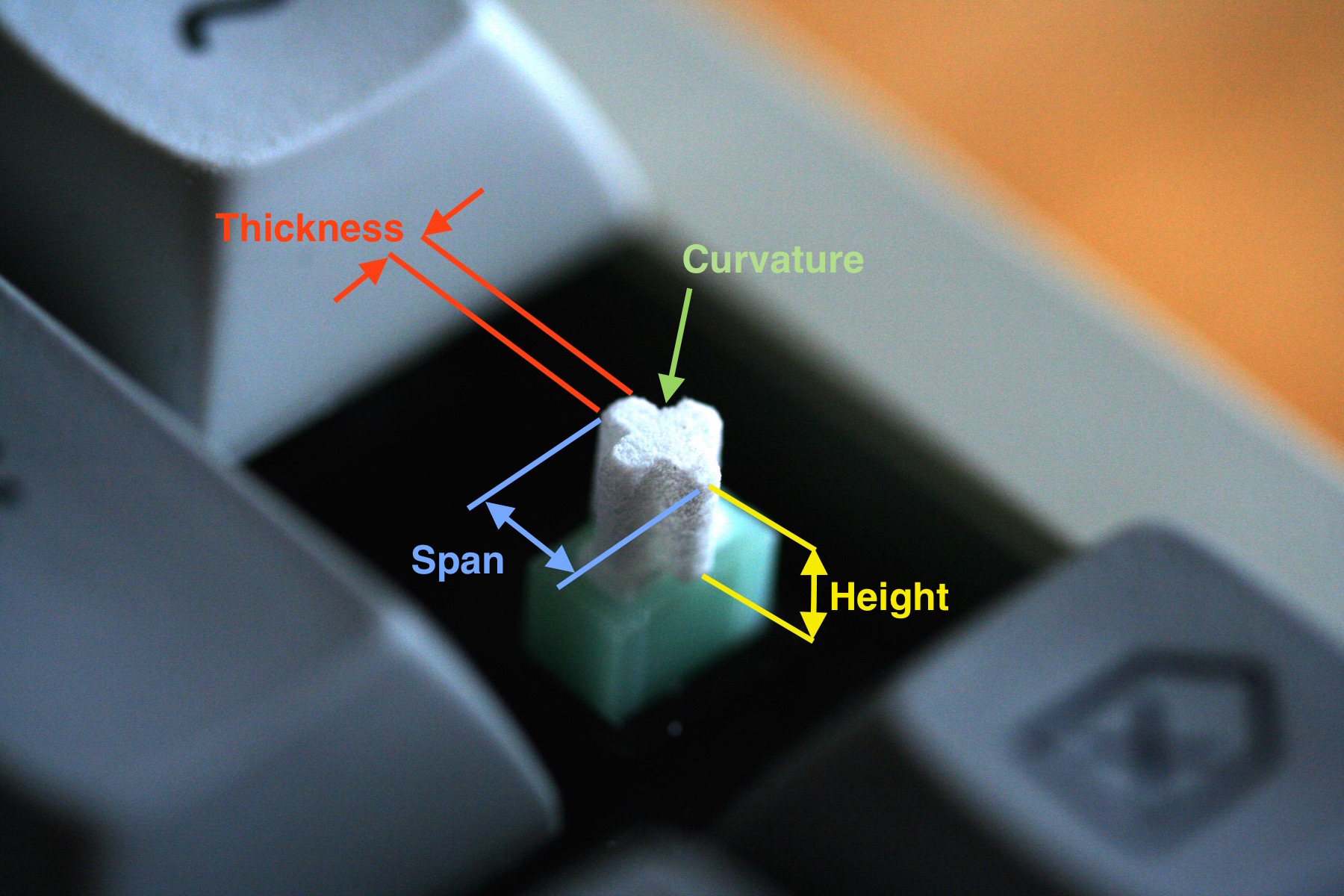

Hi All, I'd really like to scan and then print Costar Stabilizer Inserts. The thing is I don't have access to either a 3D scanner or 3D printer right now. Is there anyone here who has access to and expertise with these technologies?

- SL89

- ‽

- Location: Massachusetts, USA

- Main keyboard: CODE 104

- Main mouse: Logitech M570

- Favorite switch: Cherry MX Green

- DT Pro Member: 0095

They are only sold by like 2 places that I know of. (WASD Keyboards and MechanicalKeyboards.com) usually for $.50 which seems like a lot for something that can be 3D printed for MUCH cheaper. But when stock is low it can jump to $5.50 and that is just outrageous.

Also it might be worth it to see if we can fix the clearance issues (some people use tape to make them fit better into certain caps)

>I think he's just pushing my buttons on purpose. Or I hope so at least.

Muirium, I honestly am not sure what you mean by that.

Also it might be worth it to see if we can fix the clearance issues (some people use tape to make them fit better into certain caps)

>I think he's just pushing my buttons on purpose. Or I hope so at least.

Muirium, I honestly am not sure what you mean by that.

- pyrelink

- Location: USA

- Main keyboard: HHKB 2

- Main mouse: CST L-Trac

- Favorite switch: Capacitive Buckling Spring

- DT Pro Member: -

Button pushing aside, I do like the idea, however I am very leery of putting anything 3D printed - let alone factory made Costar stab inserts - into my beautiful keycaps. I have now lost countless keys to snapped off inserts and my last trial with MX->Topre 3D printed sliders was not pretty.

- SL89

- ‽

- Location: Massachusetts, USA

- Main keyboard: CODE 104

- Main mouse: Logitech M570

- Favorite switch: Cherry MX Green

- DT Pro Member: 0095

I'm not sure what he means by that so I hope he clarifies...

I've never had an issue with OG inserts or any experience with 3D printed components at all. There are lots of plastics it seems and resolutions to experiment with.

I've never had an issue with OG inserts or any experience with 3D printed components at all. There are lots of plastics it seems and resolutions to experiment with.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

That's my point. Try some 3D printed components, especially ones where tolerance and structural integrity really matter, and you'll know why I roll my eyes whenever people bring it up as the answer to every conceivable problem.

3D printing is a great prototyping tool. But it compares to injection molded plastic as Blu-tack does to superglue. (If you guys in America have heard of either of those things!)

3D printing is a great prototyping tool. But it compares to injection molded plastic as Blu-tack does to superglue. (If you guys in America have heard of either of those things!)

- SL89

- ‽

- Location: Massachusetts, USA

- Main keyboard: CODE 104

- Main mouse: Logitech M570

- Favorite switch: Cherry MX Green

- DT Pro Member: 0095

I was turned onto the idea because it seems very doable for something as small as a costar stab insert. At work we have a guy testing drones for our security needs and he made these tiny little gears for one of them. Very similar in size to a costar stab and its been strong enough. Normally I think 3D printing is very much overblown and overhyped but a costar stab insert seems rather perfect for it.

Edit: Also, It cant hurt to try.

Edit: Also, It cant hurt to try.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Actually, it can.

http://deskthority.net/post194579.html#p194579

I cracked an SA cap's stem on one of these. They crumble when installed. An inherent quality of 3D print material. And that effectively dry-glues them in place. Pulling the buggers can be nasty.

http://deskthority.net/post194579.html#p194579

I cracked an SA cap's stem on one of these. They crumble when installed. An inherent quality of 3D print material. And that effectively dry-glues them in place. Pulling the buggers can be nasty.

- pyrelink

- Location: USA

- Main keyboard: HHKB 2

- Main mouse: CST L-Trac

- Favorite switch: Capacitive Buckling Spring

- DT Pro Member: -

3D printing is an incredible tool for prototyping. Its a fast and easy way to test and refine a design, before sending it off to a factory or what ever. I don't see 3D printing as an end goal by any means. Matts 3D printed MX->Topre, and Mrinterfaces MX->Alps were both fantastic proofs of concept. But for actual use they need to be molded in good plastic (like Bunnylake is doing in POM with his JT Keycaps).

- SL89

- ‽

- Location: Massachusetts, USA

- Main keyboard: CODE 104

- Main mouse: Logitech M570

- Favorite switch: Cherry MX Green

- DT Pro Member: 0095

So neither of you think its worth pursuing at all to find an alternative source? I mean I'm looking at options and seeing all sorts; ABS, Polycarb, and more... with very high resolution that can probably be sealed together with something.

- scottc

- ☃

- Location: Remote locations in Europe

- Main keyboard: GH60-HASRO 62g Nixies, HHKB Pro1 HS, Novatouch

- Main mouse: Steelseries Rival 300

- Favorite switch: Nixdorf 'Soft Touch' MX Black

- DT Pro Member: -

Don't give in to the naysayers and give up! 3D printing varies wildly. It's possible that there's a combination that works.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Yeah, possible, with experimentation and a critical eye. Just not guaranteed from the outset!

The key is to accept that whatever you try may not work, and it's more important to identify what (if anything) is wrong with it than to "la la la" all the way to a quick success story that's ultimately premature. (Hello Retrobright!)

Treat 3D printing as prototyping instead of a miracle and you'll be on the right track.

The key is to accept that whatever you try may not work, and it's more important to identify what (if anything) is wrong with it than to "la la la" all the way to a quick success story that's ultimately premature. (Hello Retrobright!)

Treat 3D printing as prototyping instead of a miracle and you'll be on the right track.

- SL89

- ‽

- Location: Massachusetts, USA

- Main keyboard: CODE 104

- Main mouse: Logitech M570

- Favorite switch: Cherry MX Green

- DT Pro Member: 0095

When did I ever say it was a one size fits all thing? I put it here in the workshop because i think there is a decent case to be made for the technology and its applications beyond one failed experiment.

I am a patient man, and I am in no rush. I'll be buying costar stab inserts until its done. But I think we can seriously use the tech to at least come up with an alternative in a pinch.

I understand you are jaded from your experiences, but I never said anything was guaranteed or expected. I am not a miracle worker nor do i have the expectation of one. Maybe it was premature of you to assume the intent I had with this endeavor, and maybe it was my fault that I didn't articulate myself properly. But it certainly can be done.

I am a patient man, and I am in no rush. I'll be buying costar stab inserts until its done. But I think we can seriously use the tech to at least come up with an alternative in a pinch.

I understand you are jaded from your experiences, but I never said anything was guaranteed or expected. I am not a miracle worker nor do i have the expectation of one. Maybe it was premature of you to assume the intent I had with this endeavor, and maybe it was my fault that I didn't articulate myself properly. But it certainly can be done.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Oh all right, go ahead and prove me wrong then, why don't you, bloody young 'uns nowadays, disrespecting their jaded naysayers…

My skepticism is about using the stuff for highly exposed mechanical parts, like slider adapters and indeed stab inserts. Anything that moves a lot, rubs, or carries force is the kind of thing I have my doubts about. Wear is the issue. The Alps adapters were an extreme case where the very first time they're inserted they wear appreciably! Not every 3D print is doomed to that exact fate. But they must last a good long stress test to win my trust!

My skepticism is about using the stuff for highly exposed mechanical parts, like slider adapters and indeed stab inserts. Anything that moves a lot, rubs, or carries force is the kind of thing I have my doubts about. Wear is the issue. The Alps adapters were an extreme case where the very first time they're inserted they wear appreciably! Not every 3D print is doomed to that exact fate. But they must last a good long stress test to win my trust!

- SL89

- ‽

- Location: Massachusetts, USA

- Main keyboard: CODE 104

- Main mouse: Logitech M570

- Favorite switch: Cherry MX Green

- DT Pro Member: 0095

Trust me, I appreciate the disclaimer and warning. No disrespect was ever intended

I am totally an amateur with this and lack both a 3D scanner and a 3D printer atm.

I think you are definitely in the right to expect mechanical parts to require a lot of wear. I will be getting some costar stab inserts (probably just abbreviate that to inserts from here on out) to test. I want to know what material they are, and how it wears. Right now I'm devising a little machine that they use to show the durability and wear of their chairs. That will just move a stab wire against it and let it run to see how many sequences it goes through and how it wears.

It almost seems silly to go through all of this for such little trivial pieces of plastic... But who knows maybe this can work out better for adapters and whatnot.

edit: too much time working from 7bit, his affinity for emoticons has rubbed off

I am totally an amateur with this and lack both a 3D scanner and a 3D printer atm.

I think you are definitely in the right to expect mechanical parts to require a lot of wear. I will be getting some costar stab inserts (probably just abbreviate that to inserts from here on out) to test. I want to know what material they are, and how it wears. Right now I'm devising a little machine that they use to show the durability and wear of their chairs. That will just move a stab wire against it and let it run to see how many sequences it goes through and how it wears.

It almost seems silly to go through all of this for such little trivial pieces of plastic... But who knows maybe this can work out better for adapters and whatnot.

edit: too much time working from 7bit, his affinity for emoticons has rubbed off

- pyrelink

- Location: USA

- Main keyboard: HHKB 2

- Main mouse: CST L-Trac

- Favorite switch: Capacitive Buckling Spring

- DT Pro Member: -

Alright, call me crazy, as I have not looked into this at all. But what about looking for a company that can manufacture Costar stabs and just have a massive group buy for the things? Would that not also achieve the goal of cheap costar stabs?