Tactility

| Draft document This document is a zeroth draft and needs editing. |

| This article requires additional photographic illustration |

| This article requires illustration in the form of diagrams |

Tactility refers to an intentionally non-linear force curve designed to be felt by the operator.

Contents

Overview

In a tactile switch, the operator feels a distinct change in resistance during the keystroke. In most cases, this results in a rise in resistance followed by a drop in resistance, after which resistance resumes rising. This can be seen in the following animation:

The majority of keyboards sold in the world today are rubber dome over membrane, which is a tactile design.

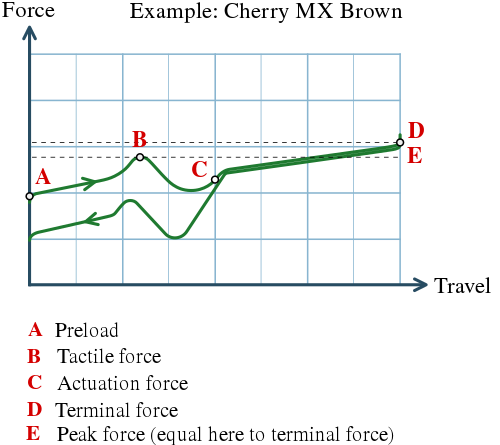

The following graph depicts a force curve of one type of tactile switch. The peak in the curve at B is the tactile peak: this is a point in the keystroke where the resistance (force) has reached a maximum, after which the force level drops off readily. The sudden drop in resistance from the switch compared with the force still being exerted on the switch typically causes it to immediately bottom out.

Advantages

Feedback

Tactility provides feedback to indicate that actuation has occurred. The operator is made aware that the keystroke was registered, even if they are not looking at the screen; for example, they may be reading from a document that they are transcribing, or operating a remote terminal session that is showing delayed input response due to connection lag. Depending on the force curve, tactile feedback can allow the operator to avoid bottoming out on keystrokes, as they can let go of the key as soon as the tactile feedback has occurred.

In this regard, tactile feedback is an alternative or a complement to audible feedback.

Key weight

A certain amount of resistance ("force" or "weight") is needed to help avoid unwanted keystrokes and to allow the operator to clearly perceive the action of pressing a keystroke. With a linear switch, the actuation force is typically half that of the force at total travel. As a result, switches with a moderate to high actuation force can feel stiff, mushy or spongy due to the continuing rise in force throughout the keystroke. With a tactile force curve, the force drops off after actuation, giving a lighter feel.

The following graph shows the force curve of Cherry ML, together with a linear force curve that intersects the tactile peak of Cherry ML. The tactile peak allows for the switch to have a fair resistance against resting your fingers on the switches, without the peak force being significantly higher than the tactile force:

Disadvantages

Obstruction

The tactile peak in a force curve obstructs operation of the key. Increased tactility results in more effort on the part of the operator to press the keys. A low-to-medium weight linear switch such as Cherry MX Red or RAFI RS 76 C 010 requires less effort, at a cost of feedback and forgiveness.

Mechanisms

There are many different approaches to providing a tactile feel. Major implementations of tactile feel are detailed below. Some of these types also generate audible feedback, which is noted as applicable.

Obstructing metal leaf

An obstructing metal leaf is a leaf spring bearing kinks that obstruct the passage of the slider. In order for the slider to pass the leaf spring, the leaf spring must be deflected out of the way; the kinks in the metal cause the slider to catch on the leaf spring, requiring a sharp increase in force to clear the obstruction.

This leaf spring can be a dedicated part, one of the switch contacts, or the actuator leaf. Alps SKCM Brown and Omron B3G-S White Tactile in particular use a modified actuator leaf placed on the opposite side of the slider. Some Mitsumi standard mechanical switches have a kinked actuator leaf instead, while Siemens STB switches use the switch contacts as the tactile leaf.

This approach may optionally provide audible feedback. If the leaf is folded back against itself, and allowed to be pulled forwards and released by the slider, a sound is generated as the spring snaps back into its rest position. A leaf spring in this configuration is called a click leaf.

The effectiveness of tactile leaves is debatable. The most successful non-audible implementations appear to be Alps SKCM Orange, Alps SKCM Brown, Alps SKCM Green and SMK second generation. When a click sound is permitted, the tactile feel is always sharpened and strengthened. A compromise implementation is Alps SKFS White, which uses a click leaf but has an empty space behind it to prevent impact occurring when the leaf is released; this gives a stronger tactile response without the accompanying sound.

The official force curves for 1994 Alps switches depict the difference between Alps SKCM Green and all other types of SKCM (tactile) switches, showing how the force curve of green differs:

The force curve of Alps SKCM Brown is confirmed to be the same as what Alps depicted for Alps SKCM Green.[1]

Non-linear slider surface

Cherry MX switches in particular are notable for a non-linear engaging surface on the slider. A protrusion from this surface provides a non-linear feel without any accompanying sound. Generation of sound has not been achieved with this design. Older Cherry switches are also known to be tactile, but only Cherry M9 has a confirmed tactility implementation, which is a related approach.

Inverting metal leaf

A number of switch designs use a "plate spring", a leaf spring that is bowed upwards in its resting state. As pressure applied to the top of this leaf, it eventually inverts such that it is now bowed downwards. This inversion is an instantaneous event, and can generate a loud sound. The total motion of this inverting action is comparatively low, so a motion reducer is required, typically a helical spring placed between the slider and the plate spring. This "stacked spring" arrangement provides the desired full travel as well as hysteresis.

Rubber dome

A rubber dome provides a number of functions, including actuation (when conductive), tactile feel, and sealing (when implemented as a rubber sheet). In terms of tactile feel, a rubber dome functions similarly to an inverting metal leaf, but the dome collapses instead of inverts.

When buckling rubber is added to an existing switch mechanism to provide tactility (as with ITW magnetic valve, BTC foam and foil, Key Tronic foam and foil and SMK spring over membrane) the dome has a hole in the centre; this design is referred to as "buckling rubber sleeve" as the rubber part does not form a complete dome.

Bowed helical spring

There are multiple ways to use a helical spring to generate tactility.

Buckling spring switches involve a laterally bowed, vertically orientated helical spring being pressed downwards. When a certain threshold is reached, the spring buckles, or snaps outwards suddenly. The containing chamber ("barrel") that guides the slider obstructs the path of the spring, causing a collision and a corresponding sound.

ITT ETL18 switches place the helical spring horizontally across the switch, which is assumed to be bowed upwards within its slot. The spring runs through the slider, and pressing down on the slider causes the spring to be first compressed before the slider can pass, after which the spring is now exerting force downwards on the slider. In effect this is a similar principle to stacked spring, but with greater travel and using only a single spring.

Mitsumi standard mechanical switches and most tactile Mitsumi miniature mechanical switches achieve tactility using a similar principle. Here, instead of the spring passing through the slider, the spring is held by the slider and a raised nub within the switch presses on the slider instead. This approach results in a much rougher feel, while ETL18 is very smooth.

References

- ↑ Plotly — Make charts and dashboards online