Out of the box, it was pretty damn dirty. Partially sticky, pen drawings on the case, peeling, chipping, and eroding paint, and grimy. Just what I expected from a bank teller's keyboard. On the back the label was still intact. It was manufactured in the Armonk, NY factory, January 1985. There is also a stamp on the inside of the top case that says January 25, 1984, as well as a stamp on the bottom half of the case that says December 8, 1984. First impressions of typing on the keyboard were good. All of the keys felt and sounded like they were buckling smoothly, with all of the stabilized keys working properly.

Soaked the keycaps in a bowl with warm water and laundry detergent for a few hours. Separated the windowed keycaps, and removed the labels. Everything looks great now, except for the tops of the windowed caps are a good deal yellowed, with some cracks in the casing.

While this is the first time I have ever cracked the case of a Model F, with the amount of reading I have been doing here on these types of boards, I felt pretty confident I could do it. And sure enough, it wasn't bad at all. The barrel plate was clearly a mess. It had corrosion and a bit of rusting, as well as crap sticking to it like crazy. The PCB is in excellent condition. Besides a minor possible issue (which I will get into later) it looks great. All of the flippers (flippies?), barrels were also looking great.

The foam however, was not okay. It was attached fine, but it was disintegrating. Its hard to describe, but some of the sections had no foam left at all. I tried to be as careful as I possibly could when removing the foam from the barrel plate, but in the end it had turned the sheets I had been working on (weird place to work I know, but that room had some good lighting for taking pictures) black with dust and bits of foam. While its not going to be easy, I am gonna have to replace the foam.

The next steps were to find a tub large enough to submerge the entire 12 pound case to soak it in detergent for a few hours. While it was soaking, I went and sanded down the barrel plate with some 600 grit sand paper. I got it as smooth and corrosion and rust free as I could. In order to keep it rust free, I taped up all of the stabilizers, and sprayed it with a few coats of Rust-Oleum, Stops Rust paint. I sanded in between each coat with 1500 grit, and gave it plenty of drying time. I am aware that it is blue, but it was the only adequate paint I could find at the time

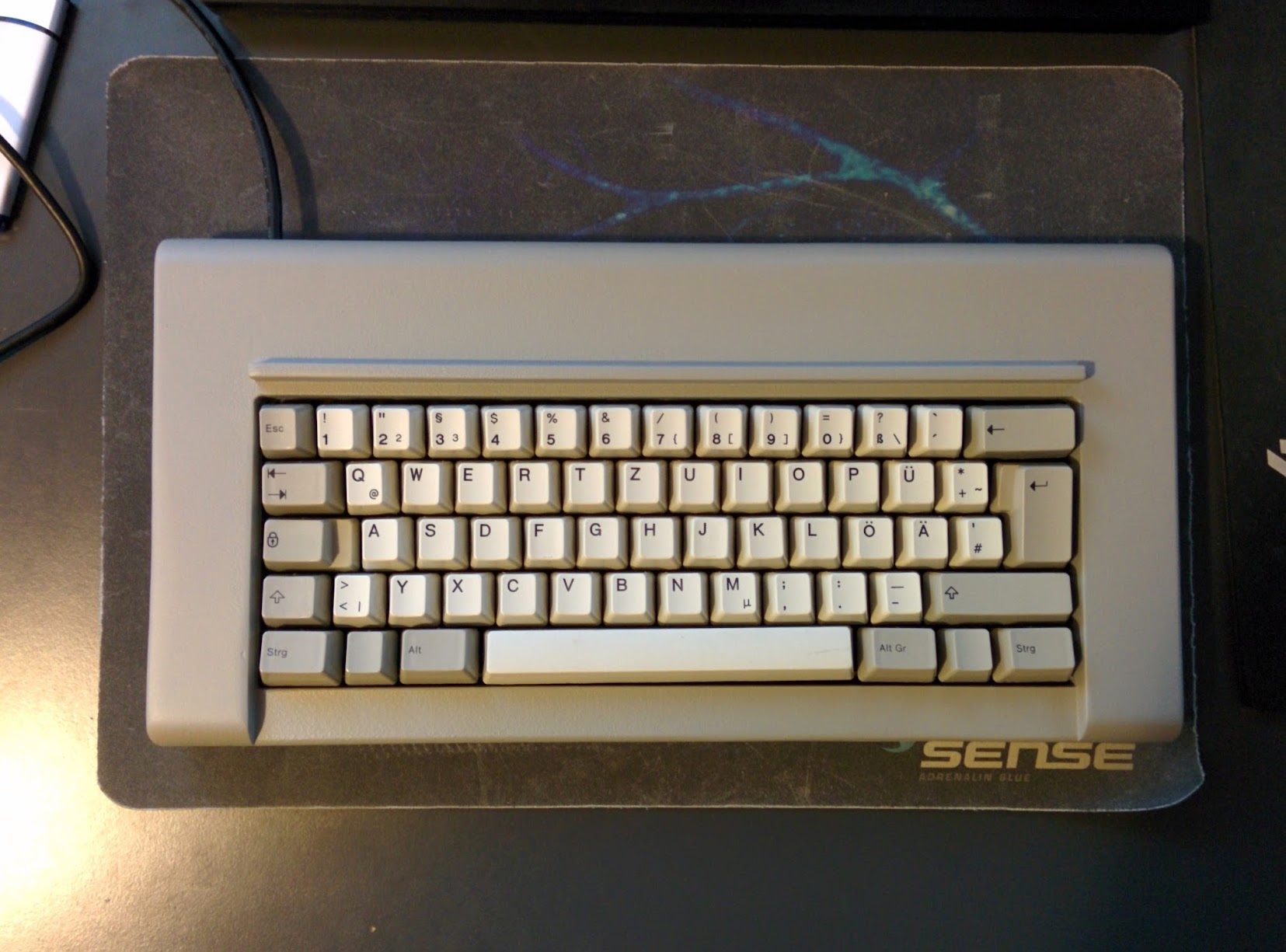

Finally, this is how everything looks after being washed, and sanded/painted. As you can see the paint does not look great. Some how it looks like I might have scratched a bit of paint off of the left hand side, and there is discoloring around the top. It looks a hell of a lot better then before, but still not perfect.

I mentioned that there was a tiny, possibly non existent problem on my PCB. It looks like a bit of the solder mask chipped away on this part of the pad. I understand the basics of how these capacitive switches work, but I can't really tell if this small chip is really going to effect anything.

That is all the work I have done so far. I am still recuperating from all the spending I did last month, so it might be another month before I am able to continue work on this. I plan to buy some of Xwhatsits controller PCBs seperately through OSHpark, and all of the components, and assemble everything myself. I need to figure out what is the best type of foam to use, and then I need to figure out what I want to do about the case.

There are already a few threads here about the best kind of replacement foam to use in these Model F's. For example:

This excellent thread

There are a lot of options to choose from. Any feedback on the foam mat, the PCB, or what to do about the case... Actually, any feedback at all would be greatly appreciated. Also let me know if the amount of pictures here was overkill, or if I should add the images into spoilers or whatever to make things load faster. I will continue to update this, when ever I make any more progress.