stuff

- scottc

- ☃

- Location: Remote locations in Europe

- Main keyboard: GH60-HASRO 62g Nixies, HHKB Pro1 HS, Novatouch

- Main mouse: Steelseries Rival 300

- Favorite switch: Nixdorf 'Soft Touch' MX Black

- DT Pro Member: -

Yeah, those were my thoughts too. I will probably end up just getting a Falbatech Dox for half the price, since Alps and an LCD probably aren't worth the price differential to me.

- RoastPotatoes

- Location: United Kingdom

- Main keyboard: HHKB

- Main mouse: PC-TRAC Deluxe +

- DT Pro Member: -

That is a nice random blog post. I would be all about reading that.

- chzel

- Location: Athens, Greece

- Main keyboard: Phantom

- Main mouse: Mionix Avior 7000

- Favorite switch: Beamspring, BS, Vintage Blacks.

- DT Pro Member: 0086

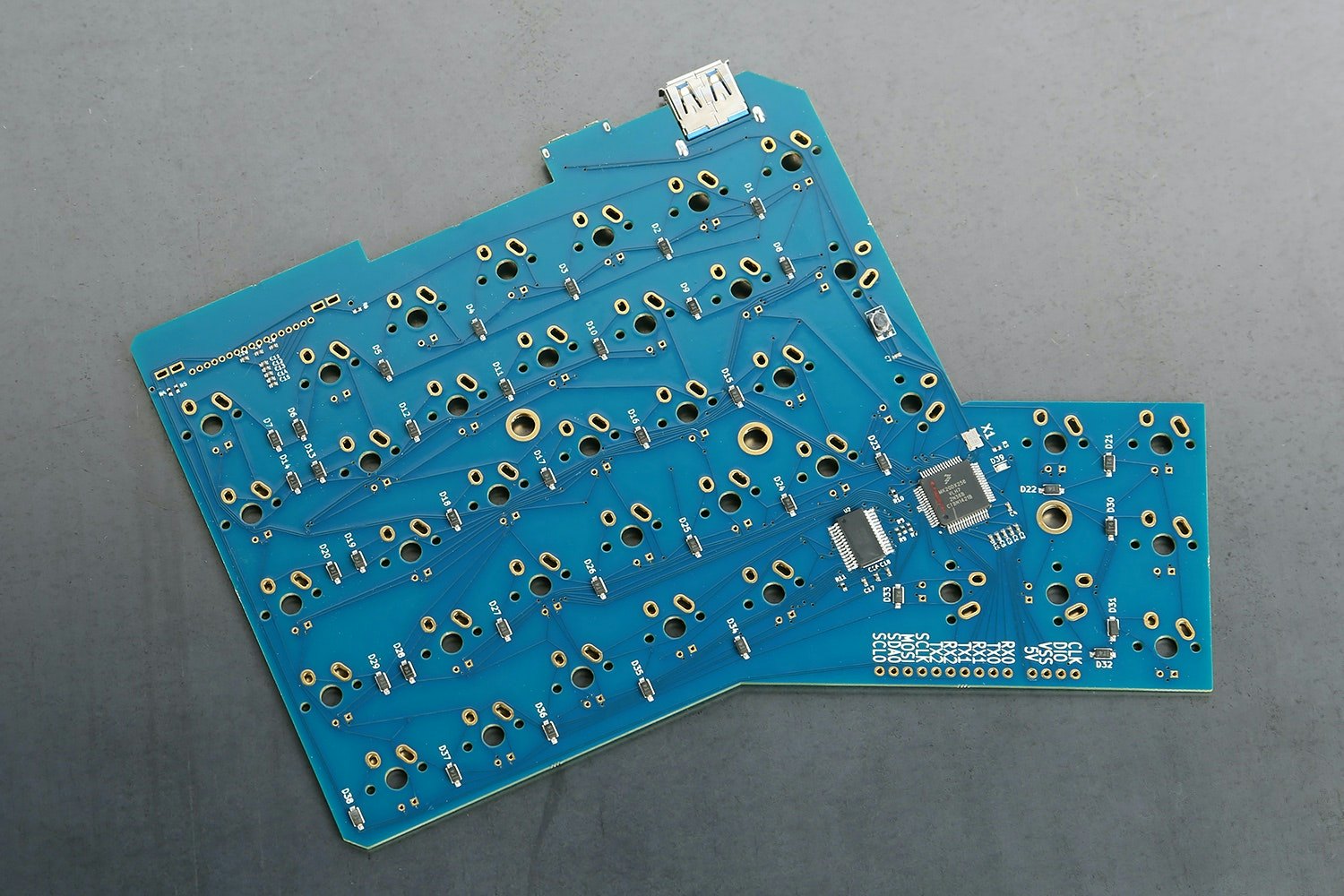

The routing makes me cringe...really cringe...vias all over the place, traces going all directions, traces too close to the switch holes...agh...Even if that is the prototype, it is BAD.

Then comes the marketing..." The first Infinity keyboard was a 60% keyboard dubbed the "HHKB 3" that was voted on by nearly 1300 people in this poll."...Really? More like 344 votes. That kind of poll result "manipulation" get on my nerves!

Other than that, it sure is nice to see development, and I really hope it has the blessing of Dox. I'd like to see the halves sold separately, eventually I might want to get a right one to use as a game-pad! Unless someone wants to split it with me (pun intended)!

Then comes the marketing..." The first Infinity keyboard was a 60% keyboard dubbed the "HHKB 3" that was voted on by nearly 1300 people in this poll."...Really? More like 344 votes. That kind of poll result "manipulation" get on my nerves!

Other than that, it sure is nice to see development, and I really hope it has the blessing of Dox. I'd like to see the halves sold separately, eventually I might want to get a right one to use as a game-pad! Unless someone wants to split it with me (pun intended)!

-

Parak

- DT Pro Member: -

Ohai! I'm the one that made that PCB. I already addressed a similar concern in the drop comments, but I welcome discussion here as well. That is, can you come up with actual technical reasons why the routing is bad, other than the subjective aesthetics?

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

http://electronics.stackexchange.com/qu ... pcb-traces

http://alternatezone.com/electronics/fi ... alRevA.pdf

- webwit

- Wild Duck

- Location: The Netherlands

- Main keyboard: Model F62

- Favorite switch: IBM beam spring

- DT Pro Member: 0000

- Contact:

I only see the registration barrier except for the third link.

Random Das Keyboard blob. As much a design fail as a smartphone, where they couldn't fit the camera and added a random blob. And for what?

Random Das Keyboard blob. As much a design fail as a smartphone, where they couldn't fit the camera and added a random blob. And for what?

-

Parak

- DT Pro Member: -

The first link actually recommends usage of rounded tracks that are in use on this board. And as far as cleanliness goes, again, that's mostly subjective. For reworking a fairly complex design such as this one I generally prefer to reroute anyway, instead of adjusting existing routing. Certainly if someone comes along later and wants to add or reroute their own components (the PCB will be open sourced), they are more than welcome to make their own manual routing.0100010 wrote:http://electronics.stackexchange.com/qu ... pcb-traces

http://alternatezone.com/electronics/fi ... alRevA.pdf

As far as the second link goes, I'm quite familiar with Dave's blog, and saw his videos on not using autorouters as well. I agree in part, but... This is not a high frequency circuit, and it has a lot of components with a fairly limited area (the original pcb was trimmed down), making it very difficult to route manually. In addition, the autorouter I use is far more advanced than the one that he's probably familiar with (Altium's), and produces much more efficient results than manual routing would ever be capable of as far as the total trace distance and number of vias is concerned.

Essentially as long as the proper rules are kept in mind and checked via DRC, a low frequency design like a keyboard doesn't particularly care if it's routed in such a manner, outside of a few important traces that I'm mindful of to route differently (or diferentially) as needed.

- webwit

- Wild Duck

- Location: The Netherlands

- Main keyboard: Model F62

- Favorite switch: IBM beam spring

- DT Pro Member: 0000

- Contact:

Das Phone.

- chzel

- Location: Athens, Greece

- Main keyboard: Phantom

- Main mouse: Mionix Avior 7000

- Favorite switch: Beamspring, BS, Vintage Blacks.

- DT Pro Member: 0086

Mostly aesthetics, but a couple of other points.

The feeling I get from the design is a feeling of rushed design.."Get it working fast so we can send it to the fab before Easter/whatever", like a hastily made up bed.

No reflections (if we were talking GHz maybe, but not here), no "symmetrically spinning axial atoms enhancing the character set". Just practical considerations beyond just getting it to work.

I am not an EE, definitely not a professional, I have designed a couple of personal projects (in Eagle), and I have found the auto-router rarely to work well, unless you restrain it so much, and go for enough passes in order of importance, that it becomes not time effective. I don't know which program/auto-router you are using, but come on, this is in no way a dense board...

I will use this artfully manipulated copy of MD's photo: Circled in red are some of the places where I'd feel uneasy designing it.

I have not seen a close-up so it might be deceiving, but there are traces reaaaaly close to the holes and to each other (what are you using, 10/10mil?).

If you trust the fab house's tolerances, fine, but why risk it?

Even if you ask and get 100% e-check, you risk more failed PCBs that will either drive up the price or push back the fulfillment time.

You have the area, why not use it? Spread out the tracks a bit, get them a bit thicker, and don't go too close to the switch solder pads.

You don't need to have the shortest path from point to point, let it breathe. DRC's are "fences" you must not cross, you don't have to lean on them all the time. If the fab house gives you 6/6mil rule and you don't need it, don't push it.

These PCBs are going to be the first soldering job for a lot of people, and quite a few will be ham-fisted. Someone will use an iron with too wide a point with a too heavy a touch, and will scratch the trace to oblivion. And will be really unhappy and he WILL blame the company and ask for a free replacement, which will either be extra cost, or bad "publicity".

Another point, standards are good, standards make our life easier and especially your friend's lives easier.

You absolutely do not have to follow rules when designing a PCB, but if you need someone to debug your circuit, or find a mis-routed track, or help you evolve it, what he sees needs to be near his comfort zone, or he will not be effective.

I really respect that you are willing to discuss your design, and please don't get offended by my comments. This style of routing is way out of my comfort zone, and definitely not the way I'd design it.

-

Parak

- DT Pro Member: -

Unfortunately I can't say exactly why it's difficult to manually route (in fact this might change when it ships to be simplified) - but it's a much denser design than the original and what you might suspect, with various complications. I think I can only mention that other boards of similar design would usually use 4 layers (raising the cost substantially), whereas I've decided to stick with 2. And yes, I've tried eagle, altium, diptrace and a few other autorouters... they were all horrible.

We do get 100% e-check, and the fab is 3/3, with me using 6/6 primarily, and 20/6 on some of the power and ground traces. 8/8 was used for Infinity, and that had no significant problems (or none that I know of even) of people killing the traces due to bad soldering and having to rewire. If anything, what would typically happen is a lifted pad, rather than a broken trace, but with the pcbs being Tg170 that is hopefully reduced as well. Traces are the regular spacing away from the holes (6 mil), so I can see how they might look a bit too close. I might make those three have larger margins, even though there's no current cause to, but that would cause longer more meandering traces due to being unable to pass as many traces between them.

Of course, the longer the traces are, the more interference they will cause for other traces. Calculation wise, you can have more overall trace length, or more vias by shortening it. More vias is also problematic as it might carry extra costs, even longer traces are problematic for other reasons such as creating larger problems with traces that need to be length matched.

And the rushed design.. well, only to some extent. This is by no means a simple 'throw into an autorouter and done' kind of thing, as there's plenty of considerations that need to be accounted for in every autoroute run. I'm also doing this primarily as a hobby, as what I do for a living is in an entirely different field. I do understand however where something is plenty good enough to work well and taking a day or two versus complete overkill that takes potentially weeks. Hopefully you can agree that at least as far as keyboards are concerned, the former is more than sufficient, even for long term or user abuse. I see these huge traces on some of the DIY designs for simple matrix scanning, and all I can think of is that nobody in their right mind is going to bother with repairing the trace, even when it's that wide - everyone is just going to bridge instead.

Hopefully, if someone needs to help us debug the design (always welcome), they won't try to follow the traces, as that would be silly in anything over 2 layers for example, and use the schematic instead.

We do get 100% e-check, and the fab is 3/3, with me using 6/6 primarily, and 20/6 on some of the power and ground traces. 8/8 was used for Infinity, and that had no significant problems (or none that I know of even) of people killing the traces due to bad soldering and having to rewire. If anything, what would typically happen is a lifted pad, rather than a broken trace, but with the pcbs being Tg170 that is hopefully reduced as well. Traces are the regular spacing away from the holes (6 mil), so I can see how they might look a bit too close. I might make those three have larger margins, even though there's no current cause to, but that would cause longer more meandering traces due to being unable to pass as many traces between them.

Of course, the longer the traces are, the more interference they will cause for other traces. Calculation wise, you can have more overall trace length, or more vias by shortening it. More vias is also problematic as it might carry extra costs, even longer traces are problematic for other reasons such as creating larger problems with traces that need to be length matched.

And the rushed design.. well, only to some extent. This is by no means a simple 'throw into an autorouter and done' kind of thing, as there's plenty of considerations that need to be accounted for in every autoroute run. I'm also doing this primarily as a hobby, as what I do for a living is in an entirely different field. I do understand however where something is plenty good enough to work well and taking a day or two versus complete overkill that takes potentially weeks. Hopefully you can agree that at least as far as keyboards are concerned, the former is more than sufficient, even for long term or user abuse. I see these huge traces on some of the DIY designs for simple matrix scanning, and all I can think of is that nobody in their right mind is going to bother with repairing the trace, even when it's that wide - everyone is just going to bridge instead.

Hopefully, if someone needs to help us debug the design (always welcome), they won't try to follow the traces, as that would be silly in anything over 2 layers for example, and use the schematic instead.

No worries

-

Findecanor

- Location: Stockholm, Sweden

- DT Pro Member: 0011

There are many tiny passthrough-holes between layers and there are some traces that are right at the edge of drill holes: and this means that manufacturing requires lot of work and tight tolerances. The old design could pretty much be etched and drilled at home or at the local makerspace.

There is no support for having two 1u keys instead of a 2u thumb key, no support for 1u keys on the outer columns and no support for PCB-mounted stabilisers. I have trouble tracing the matrix compared to bpiphany's design, but I suppose that the matrix is different where there is really no reason to because the original matrix is very tight. The new PCB also has completely different standoffs and edges to the old PCB making it not just a bit of work, but downright infeasible to modify an old case. It is also not possible to modify the PCB to add an extra key in-between the finger and thumb-cluster.

-

Parak

- DT Pro Member: -

I understand, but home manufacturability was never the target for this revision, especially with the usage of many small smd components and tight pitch spacing on the leaded parts. Unfortunately, neither were the optional key placements, though I'll ask about that. Since all the components of this will be open sourced, anyone can of course take the design and route it or modify it for non-smd however they see fit for their own needsFindecanor wrote:There are many tiny passthrough-holes between layers and there are some traces that are right at the edge of drill holes: and this means that manufacturing requires lot of work and tight tolerances. The old design could pretty much be etched and drilled at home or at the local makerspace.

There is no support for having two 1u keys instead of a 2u thumb key, no support for 1u keys on the outer columns and no support for PCB-mounted stabilisers. I have trouble tracing the matrix compared to bpiphany's design, but I suppose that the matrix is different where there is really no reason to because the original matrix is very tight. The new PCB also has completely different standoffs and edges to the old PCB making it not just a bit of work, but downright infeasible to modify an old case. It is also not possible to modify the PCB to add an extra key in-between the finger and thumb-cluster.

Also, not exactly sure how this relates to the usage of an autorouter, since these concerns would apply even if I routed same trace widths manually

-

jacobolus

- Location: geekhack ergonomics subforum

- Favorite switch: Alps plate spring; clicky SMK

- DT Pro Member: -

It seems to me that this was one of the primary design goals of the old design. It’s obviously not a goal of the new design. Do you think it should be?Findecanor wrote:The old design could pretty much be etched and drilled at home or at the local makerspace.

IMO, once the controller is integrated directly onto the PCB instead of using a pre-assembled Teensy, there stops being much reason to design the rest of the board for someone to etch and drill at home. Would you expect DIY hobbyists to buy all the chips directly and do handle surface-mount soldering them all to the board?

-

aslomage

- Location: Los Angeles, CA

- Main keyboard: Kinesis Advantage

- Main mouse: plain old mouse / logitech trackman

- Favorite switch: Cherry MX Brown

- DT Pro Member: -

I just joined this drop at Massdrop after waiting two months for the Falbatech Dox to arrive, and after spending more than $250 on it that I'll probably never see again. To be fair to Falbatech, it's not their fault, it's the polish post (Poczta Polska) that is not delivering the package, but Falbatech is certainly not helping, and has started ignoring my messages. In case people were thinking about going with them, I though I'd share my experience.

That said, it seems that this Infinity ErgoDox is an even better option, I really hope we'll get it soon, and I also hope it's easy to solder, cause I'm usually pretty bad at soldering

I love my Kinesis Advantage, but it's a little too big to carry around, and also, it's raised a little too much that sometimes it's uncomfortable. That, and I love the programmability of the ErgoDox.

I have the Grifiti ErgoDox pads (bought while waiting for the falbatech one ... heh), so hopefully they fit this one too

As for the routing, yes, it looks ugly, but as long as it works fine, I don't care.

- scottc

- ☃

- Location: Remote locations in Europe

- Main keyboard: GH60-HASRO 62g Nixies, HHKB Pro1 HS, Novatouch

- Main mouse: Steelseries Rival 300

- Favorite switch: Nixdorf 'Soft Touch' MX Black

- DT Pro Member: -

Yeah, Poczta Polska are utterly useless. I spend some time in Poland and have never had a good experience with them. I always, ALWAYS use a courier in Poland if the item is worth any amount of money at all.

-

aslomage

- Location: Los Angeles, CA

- Main keyboard: Kinesis Advantage

- Main mouse: plain old mouse / logitech trackman

- Favorite switch: Cherry MX Brown

- DT Pro Member: -

Oh wait, nevermind ... just now (April 1st), there's a new status update on the package tracking page (shipped February 11) stating my falbatech dox made it to the US. Hopefully it's not a April's fools joke!

Well, it seems I'll get to compare the Infinity with the "Classic" variants after all ...

Well, it seems I'll get to compare the Infinity with the "Classic" variants after all ...

-

Findecanor

- Location: Stockholm, Sweden

- DT Pro Member: 0011

I see the amount and required precision of the holes as the worst difficulty, even for getting them fabricated cheaply.

I think that many serious electronics enthusiasts are able to do surface-mount soldering. I see a lot of it at electronics forums and I think that makerspaces that cater to electronics often have SMT ovens. (I think my local maker-space does, anyway)

- HaaTa

- Master Kiibohd Hunter

- Location: San Jose, California, USA

- Main keyboard: Depends the day

- Main mouse: CST L-TracX

- Favorite switch: Fujitsu Leaf Spring/Topre/BS/Super Alps

- DT Pro Member: 0006

- Contact:

I did some of the early prototypes myself (hand soldered). Takes a bunch of hours though even with the right tools.

-

jacobolus

- Location: geekhack ergonomics subforum

- Favorite switch: Alps plate spring; clicky SMK

- DT Pro Member: -

Sure, fine. But anyone with an SMT oven who wants to etch and drill their own PCBs and buy all the surface mount components from Mouser (or scrounge them from their own part bins) can probably also handle a bit of PCB design, no?

I just don’t understand why the needs of “serious electronics enthusiasts” who want to DIY everything from scratch should have any bearing on the PCB routing of a commercial keyboard or halfway pre-soldered kit.

Someone that dedicated probably wants to customize the layout, anyway, if they’re planning to put that much work in.

-

Findecanor

- Location: Stockholm, Sweden

- DT Pro Member: 0011

I did not have such a small group in mind, but the opposite: I think one should strive for making a DIY keyboard have as many options open as possible.

A PCB with more readable (more "aesthetically pleasing") routing would also be easier to mod. Not just by changing the PCB design before etching, but also by modifying already-printed PCBs with direct wiring. There are several people who have done that with the ErgoDox in various ways to get new keys, move keys, move/add LEDs or to add support for foot pedals, break away the thumb cluster etc.

I don't think that Dox or bpiphany thought of any of those things when they designed the keyboard, but I think it is great that people did that. I think that such tinkering: such evolution of the ErgoDox design, should be encouraged by design if possible. You have yourself posted evolved ErgoDox designs and acclaimed others that have done it.

There will come a time when Massdrop stops making ErgoDoxen. By then the home-etching scenario will be more relevant than now.

-

jacobolus

- Location: geekhack ergonomics subforum

- Favorite switch: Alps plate spring; clicky SMK

- DT Pro Member: -

That’s a fair point.

Yeah, I just don’t think having access to the PCB matters for that. A keyboard matrix just isn’t that hard to hand wire or design a new PCB for.

- orcinus

- Location: Zagreb, Croatia, EU

- Main keyboard: CM QuickFire TK red

- Main mouse: Logitech G700

- Favorite switch: Cherry MX red

- DT Pro Member: -

You really *really* don't need an oven to solder SMD boards.Sure, fine. But anyone with an SMT oven who wants to etch and drill their own PCBs and buy all the surface mount components from Mouser (or scrounge them from their own part bins) can probably also handle a bit of PCB design, no?

And SMDs are no more complicated to solder than through hole components.

I'll never understand why people make it sound like some insurmountable obstacle reserved for people with special knowledge, skills or equipment. If anything, SMD's are actually easier and faster to solder by hand than through hole. All you need is flat tip that's not too big nor (more importantly) too small (error people often make) and a spool of solder wick. Liquid flux helps (but you should already have some for through hole anyways if you don't want a mess).

- orcinus

- Location: Zagreb, Croatia, EU

- Main keyboard: CM QuickFire TK red

- Main mouse: Logitech G700

- Favorite switch: Cherry MX red

- DT Pro Member: -

In this universe.

This attitude is exactly what i'm talking about.

It takes you literally 10 minutes max to learn how to solder SMDs by hand. And it takes very little practice once you do.

This attitude is exactly what i'm talking about.

It takes you literally 10 minutes max to learn how to solder SMDs by hand. And it takes very little practice once you do.