Let's create the FSSK/FEXT = DONE !!!!

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

My conclusions are:

1.- Some missing holes

2.- Some error in the printing. Small

3.- Some errors in the position of the holes. The error is bigger than the printing error.

I guess that I need to learn how to create the PCB file, if not, the process will take ages.

My problem again is that I am very busy at present.

1.- Some missing holes

2.- Some error in the printing. Small

3.- Some errors in the position of the holes. The error is bigger than the printing error.

I guess that I need to learn how to create the PCB file, if not, the process will take ages.

My problem again is that I am very busy at present.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

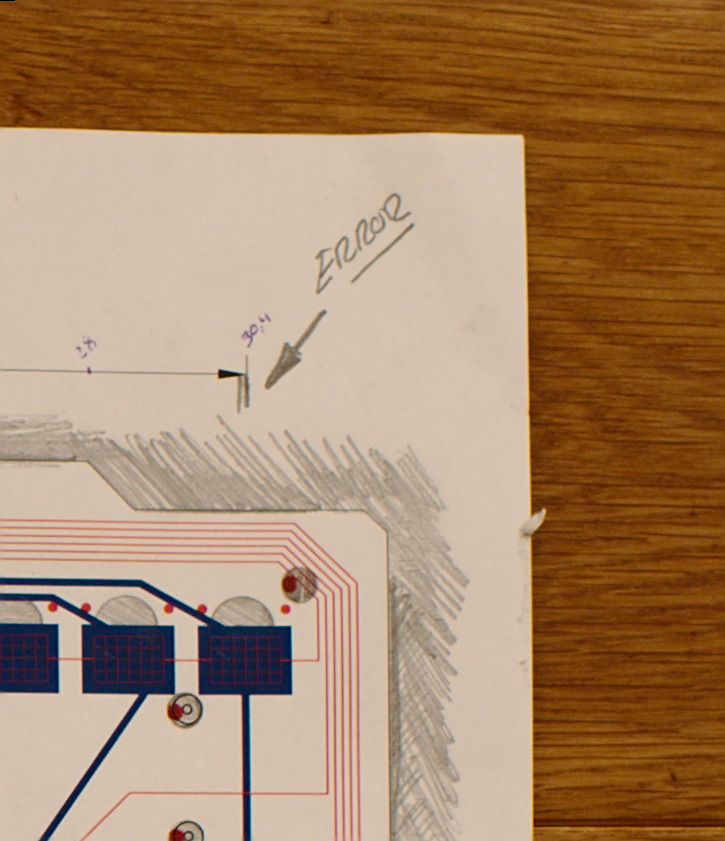

Regarding the errors comparison:

in this picture, if the border of the plastic is compared with the position of the hole, one can see that the displacement errors do not match

On the other hand, the hole error (red) is matching the printing error ... I cannot conclude if it is correct or not.

in this picture, if the border of the plastic is compared with the position of the hole, one can see that the displacement errors do not match

On the other hand, the hole error (red) is matching the printing error ... I cannot conclude if it is correct or not.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

I also conclude that for the prototypes, it is not recommendable to order the PCBs with the holes done.

One can always drill them with enough precision.

This will remove a potential failure mode. I many PCBs are required after the initial prototypes (I do not think that this will be the case) they could be added later.

One can always drill them with enough precision.

This will remove a potential failure mode. I many PCBs are required after the initial prototypes (I do not think that this will be the case) they could be added later.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Sterling work, i$. I'm in no rush anyway as my barrel frame is in America while my SSKs are all in Scotland! I'm many months away from getting things together even if I wanted.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

Sure, we can silkscreen where we think they should go.

Would you please try the paper template on the back plate to check for that hole above F1? I know that is not correct. I need to get closer as I want to use it for grounding.

Thanks

- XMIT

- [ XMIT ]

- Location: Austin, TX area

- Main keyboard: XMIT Hall Effect

- Main mouse: CST L-Trac Trackball

- Favorite switch: XMIT 60g Tactile Hall Effect

- DT Pro Member: 0093

Sorry, it looks like idollar beat me to the punch here, as I was looking to print these out in the office. Ah well. Maybe I can be of help some other way.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

If you're still willing, it might be worthwhile to make a second set of measurements just to double-check. Measure twice and drill once, you know...XMIT wrote:Sorry, it looks like idollar beat me to the punch here, as I was looking to print these out in the office. Ah well. Maybe I can be of help some other way.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

Alright: The following pictures are bad quality. The tripod is stored back. I was on my way to bed

I have placed the paper on the back of the metal plate. Looking down. Using the "pencil" technique that we all used when kids to copy coins I marked where the screws are. I then made holes with the top of the pencil to see where they were.

The results follow:

There is some lateral displacement:

More details follow:

Notice the lateral displacement again. I have folded the paper and marked the fold with a dashed line

-

cinnamonrollz

- Location: Wisconsin, USA

- Main keyboard: Model F Unsaver

- Main mouse: A turd logitech wireless mouse

- Favorite switch: Buckling Spring/Blue Alps/Beam spring

I only have fullsized model m's but I would be interested in one of the prototype pcb's. If they work, this would be an awesome design.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

If the FSSK works, doing the FEMK (F Extended model M Keyboard) should be trivial.

The only issue, once more, are the F flippers that one need to source someone. But we will deal with this latter. One problem at a time is enough.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Too many acronyms!

Apparently, Unicomp still has spare SSK barrel frames in stock, after all these years. Those should all be the last revision of IBM's design, and a known starting point. Could be a good idea to prototype this mechanism with one of them.

Apparently, Unicomp still has spare SSK barrel frames in stock, after all these years. Those should all be the last revision of IBM's design, and a known starting point. Could be a good idea to prototype this mechanism with one of them.

-

Vizir

- Location: Tulsa, OK

- Main keyboard: IBM Model F 122 / HHKB2

- Main mouse: Roccat Nyth

- Favorite switch: B/S / Topre

- DT Pro Member: -

You could source them from Ellipse's new F62/77 project.idollar wrote:If the FSSK works, doing the FEMK (F Extended model M Keyboard) should be trivial.

The only issue, once more, are the F flippers that one need to source someone. But we will deal with this latter. One problem at a time is enough.

- hammelgammler

- Vintage

- Location: Germany

- Main keyboard: IBM Model F Unsaver

- Main mouse: G-Wolves Skoll

- Favorite switch: Buckling Spring (Model F)

- DT Pro Member: -

Any news with the project?

Oh yeah, do you plan a PCB with windows keys between CTRL and ALT? Or exactly the normal SSK layout?

Oh yeah, do you plan a PCB with windows keys between CTRL and ALT? Or exactly the normal SSK layout?

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

Hello,

I spend some time today to model the holes in the FSSK.

The next step is to paint the pads.

I decided to make my own version so we can compare the two independently made pcbs at the end as a kind of quality control.

There is no logic with these holes. One has just to measure, print and correct. A nightmare.

I need to find some time to continue with this.

I spend some time today to model the holes in the FSSK.

The next step is to paint the pads.

I decided to make my own version so we can compare the two independently made pcbs at the end as a kind of quality control.

There is no logic with these holes. One has just to measure, print and correct. A nightmare.

I need to find some time to continue with this.

- Attachments

-

- FSSK-v2.1.jpg (202.33 KiB) Viewed 7352 times

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

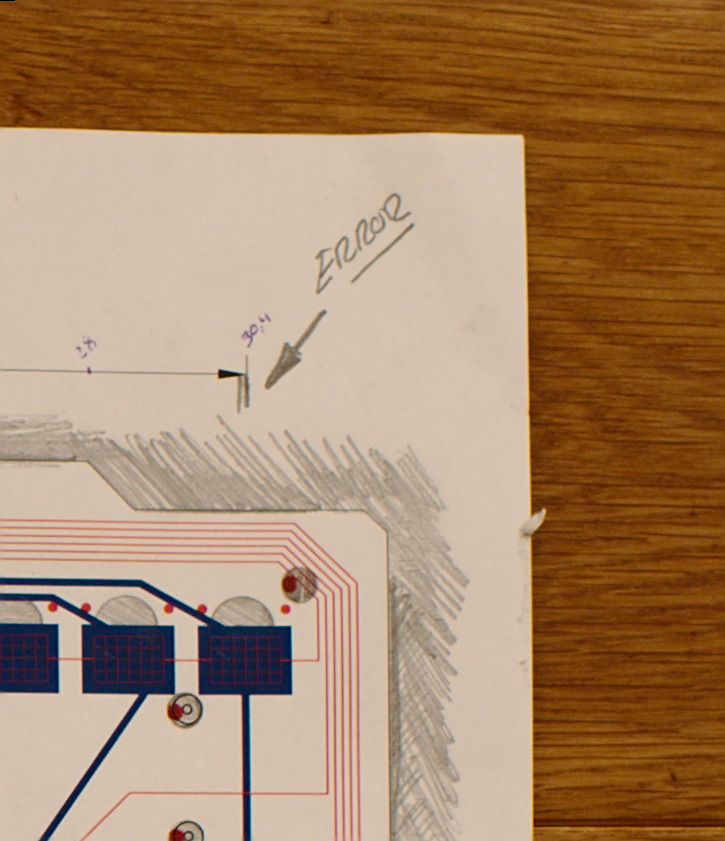

In general the file works fine.

The extended model M has he holes in the same order. So I am thinking of creating a CAD file with one extra set of layers to cover the normal model M also:

I need to correct some errors. The holes are only there to avoid routing copper through this area. The plan is to order the PCB without the holes. But we better do things right from the beginning. This needs to be corrected:

I hope to progress this during the weekend. Lets see if we have a full PCB by then.

The extended model M has he holes in the same order. So I am thinking of creating a CAD file with one extra set of layers to cover the normal model M also:

I need to correct some errors. The holes are only there to avoid routing copper through this area. The plan is to order the PCB without the holes. But we better do things right from the beginning. This needs to be corrected:

I hope to progress this during the weekend. Lets see if we have a full PCB by then.

- vivalarevolución

- formerly prdlm2009

- Location: USA

- Main keyboard: IBM Beam spring

- Main mouse: Kangaroo

- Favorite switch: beam spring

- DT Pro Member: 0097

Great to see some progress. Not sure what you are thinking for the PCB fabricator, but I used PCBway for the XTant and I was happy with their pricing and quality.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

Thanks for the tip. I will check it, for sure.vivalarevolución wrote: Great to see some progress. Not sure what you are thinking for the PCB fabricator, but I used PCBway for the XTant and I was happy with their pricing and quality.

- shreebles

- Finally 60%

- Location: Cologne, Germany

- Main keyboard: FaceW 45g Silent Red /NerD60 MX Red

- Main mouse: Logitech G303 / GPro (home) MX Anywhere 2 (work)

- Favorite switch: Silent Red, Old Browns, Buckling Spring,

- DT Pro Member: 0094

Nice! This is the single most promising keyboard project that I know of. Having tried your F, I can only imagine how awesome this could be...

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

We may get some more traffic in this thread, idollar, since I linked it in Ellipse's 4704 revival thread (which is nearing completion). Do you have any updates on this project for us?

- shreebles

- Finally 60%

- Location: Cologne, Germany

- Main keyboard: FaceW 45g Silent Red /NerD60 MX Red

- Main mouse: Logitech G303 / GPro (home) MX Anywhere 2 (work)

- Favorite switch: Silent Red, Old Browns, Buckling Spring,

- DT Pro Member: 0094

Wow! So you will build a complete, hopefully working prototype? Exciting!