All,

I know that you may be already tired of my posts with the changes that I have been doing to the PCB.

I only hope that this will be the final post with the FSSK prototype layout with is already in its version v0.47 !!!

The changes in this version, which will as I said hopefully the latest one, are:

- 1.- I realised by looking at the gerber files that the mounting holes on the top part of the PCB were not oval. This would have meant manual cutting of the PCB to allow the montage. Diptrace does not offer oval holes, or at least I could not find how to do it. The solution was to add three holes in a row. This trick should do the job.

2.- I have reviewed the space between the upper and bottom layers to check if there was room to make the holes bigger. This will minimize the risk of misalignment with the real keyboard. I have checked it with printouts, but believe me, it is tricky. Just the fact of presenting the printout on to the wrong side of the metal plate makes a difference !

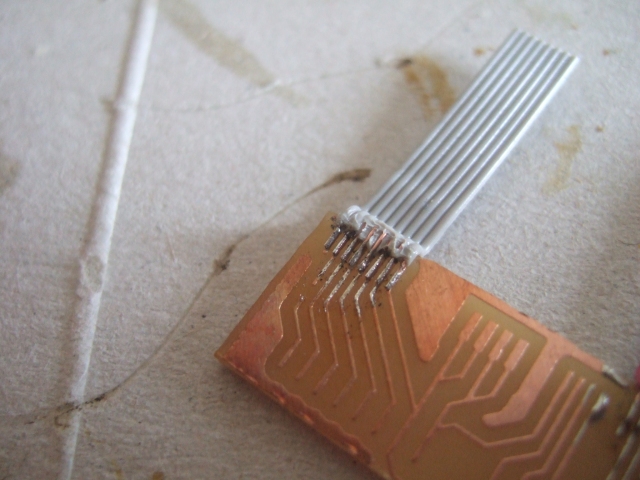

3.- I discarded the idea of having a module for the numpad that could be linked to the FSSK. Soldering the interface that I have shown before will be impossible, not to say that the holes will get in the middle. We will stick to the original idea of having two different versions of the PCB.

4.- I have closed the ground lines in the bottom side when the numpad is not present. This will improve the grounding which is critical for the success.

5.- I have changed a couple of upper traces which were routed close to the middle holes. I have used "incline" traces to move as far as possible from the bottom layer and the holes.

6.- I also checked the price for 0.6 mm instead of 0.4 mm PCBs. For 10 units, the different is approximately $100 extra on top of the $180 that the 0.6mm will cost. We will order 0.6mm. Additional to this we will have to pay some import duties that I estimate to be some 20 euros.

The order is waiting review from the producer. So hurry up if you want to contribute to the prototyping phase !!!!

Regarding the contribution to the prototyping:

I have sent an email to the people the have shown some interest proposing ordering 5 units instead of the 10 that I originally proposed. If the design works fine, I proposed to run a lottery among the contributors. The winner would have gotten the prototypes after paying the additional shipping cost.

With the new (estimated) price for the 0.6mm this will not be longer required. Thus, we discard this proposal and stay with the 10 units. As we are very close to the purchasing, please register today using a PM to me. I will answer back with the paypal details to transfer your contribution: (180+20)/8 = 25 euros.

In the above you can read that I have added the import taxes and assumed that euros and dollars are the same. This will add some extra cost, but it will also cover some of the interested contributors that may drop out.

Note that if the PCB works, in order to get it in your place, you will need to add some local shipping costs on top.

Alright, following the files:

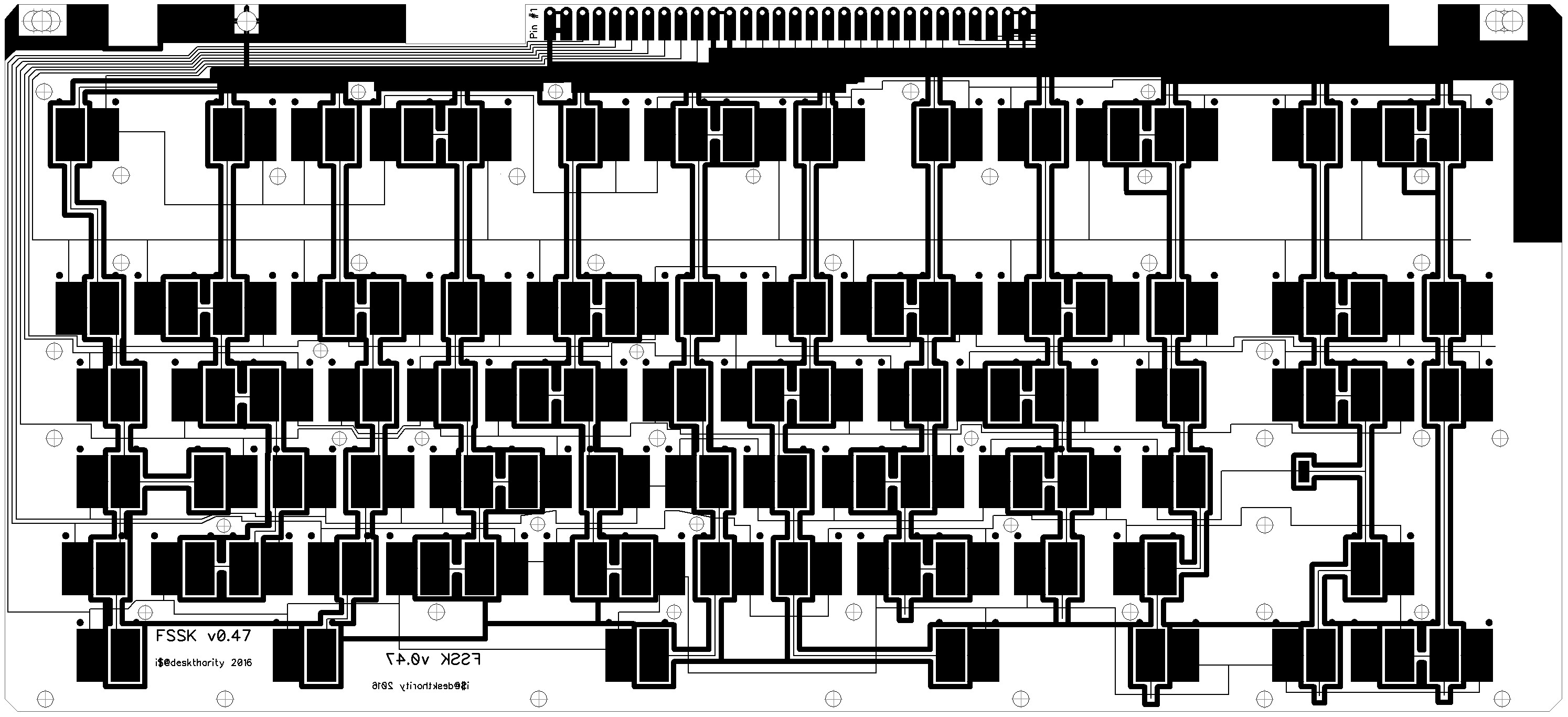

- FSSK - Diptrace v0_47 - both.jpg (594.01 KiB) Viewed 8883 times

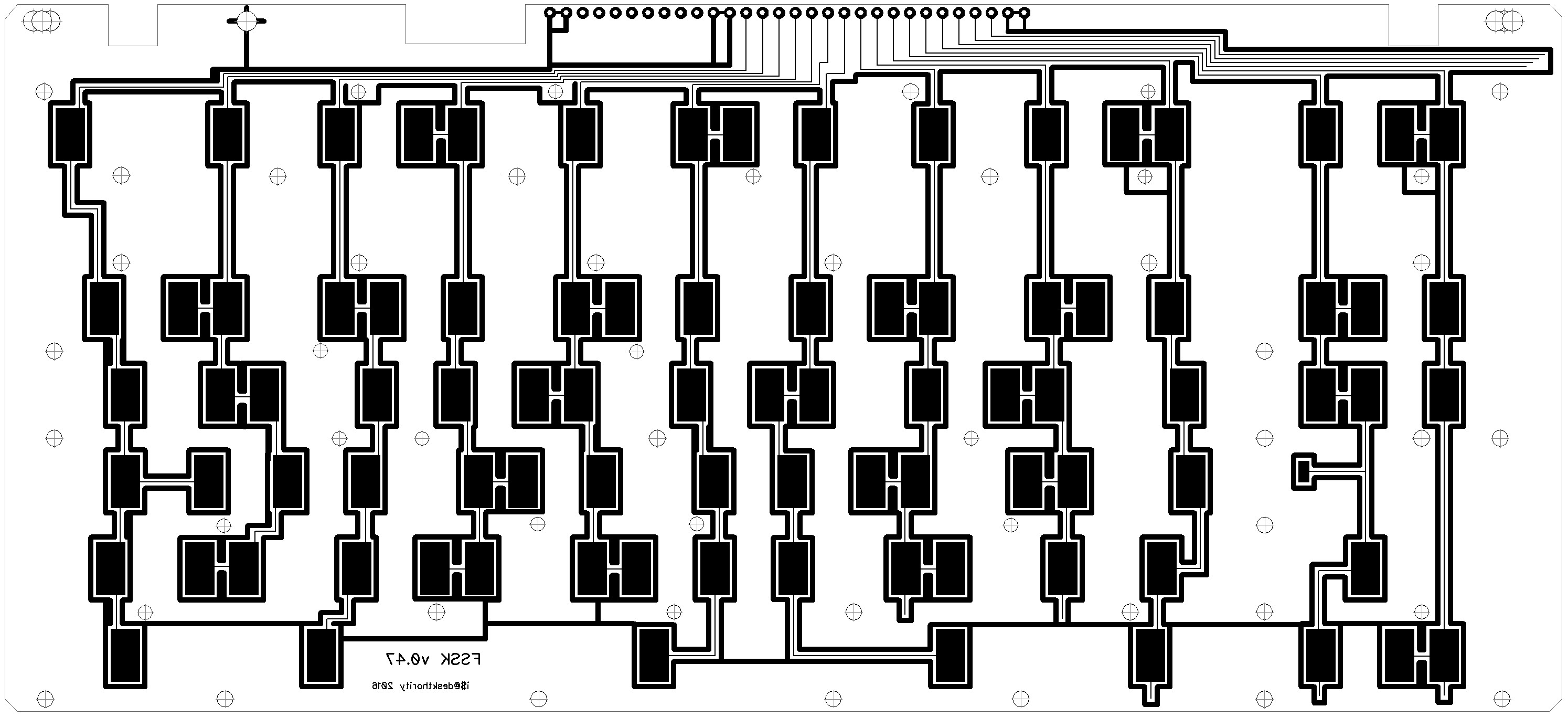

- FSSK - Diptrace v0_47 - bottom.jpg (462.19 KiB) Viewed 8883 times

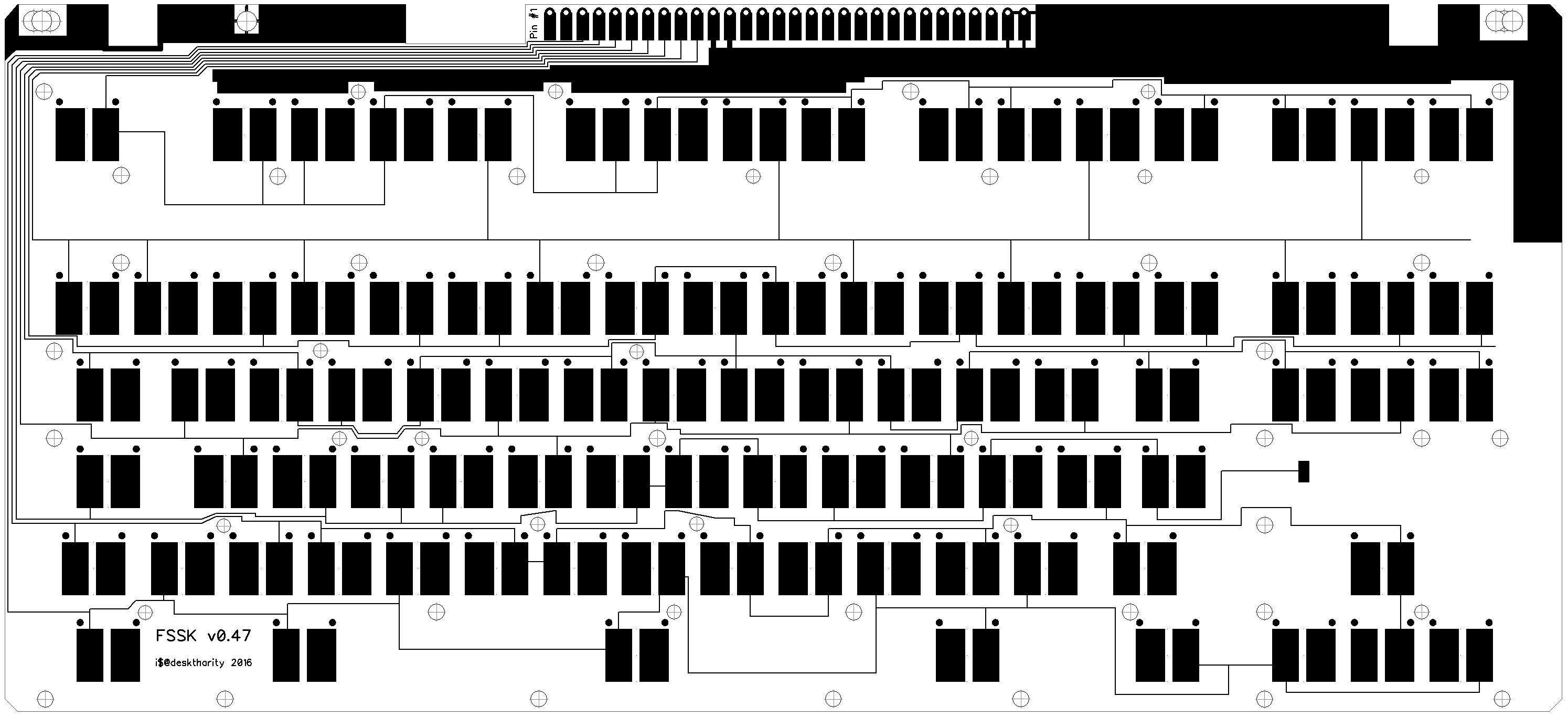

- FSSK - Diptrace v0_47 - top.jpg (439.03 KiB) Viewed 8883 times

Deltacad file:

Diptrace file:

And Gerber sent to the producer:

----------------

LAST Reminder ?

----------------

I have created the following spreadsheet to collect the interest and contributions in this project.

Click here

Please write down your interest/preferences. A

nd send me a PM.