Custom "75%+1" layout with "Danger Zone" Caps & Dyed Gateron MX Tops

- Plasmodium

- Location: UK

- Main keyboard: QPAD MK80

- Main mouse: Logitech LX3

- Favorite switch: Cherry brown

- DT Pro Member: -

There's also a Teensy 2.0 ++ model with extra pins. If I'm not mistaken, it's exactly the same hardware as the standard 2.0 (so the same well-known software) but with extra pins - perfect for having the 75% + the detachable numpad on the same controller, I'd say.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

I won't lie... A 72 MHz keyboard does seem downright silly!

Ugh... I was hoping to avoid ordering one. No matter how I break it down, I'm gonna have to spend another $20+, and wait for it to show up in the mail.

Okay... new question... Keyboard angles? What is generally typical? The keys are all row 3 Signature Plastics’s SA profile, so all uniform, and the plate is flat. since the angle will be determined by the angle I cut the side wood pieces (and the height of the front vs rear piece), I'll have to get it fairly close from the start (I can slightly adjust it with variations in rubber feet, etc). What do people find to be comfortable (when using a flat R3 Signature Plastics’s SA profile key cap set). This is my first keyboard build, so I'm kinda open to suggestions.

Ugh... I was hoping to avoid ordering one. No matter how I break it down, I'm gonna have to spend another $20+, and wait for it to show up in the mail.

Okay... new question... Keyboard angles? What is generally typical? The keys are all row 3 Signature Plastics’s SA profile, so all uniform, and the plate is flat. since the angle will be determined by the angle I cut the side wood pieces (and the height of the front vs rear piece), I'll have to get it fairly close from the start (I can slightly adjust it with variations in rubber feet, etc). What do people find to be comfortable (when using a flat R3 Signature Plastics’s SA profile key cap set). This is my first keyboard build, so I'm kinda open to suggestions.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

And it's ordered...

Went ahead and ordered two Teensy 2.0 boards. A Teensy 2.0++ wouldn't really do me all that much use, as I'd need to feed something like 11-12 wires to an external number pad to use it in that manner. It makes far more sense to use a port extender, like how it's done in the Ergodox. Then you can just use a a four conductor cable (like a phone cord or a TRS connector with an extra ring) and communicate with I2C.

Now, speaking of that... I've seen some people use the MCP23017 and others use the MCP23018.They seem rather similar. One appears to be strictly open drain output on the GPIO, one seems to have more I2C address configurations. Is there a preference among the community, or a preferred chip for use with the firmware? I'd love to get it ordered at some point, even if I don't use it right away. Is the Teensy software written to prefer one or the other. Also, how does the Teensy handle hot swapping on the I2C. Can the firmware be configured to gracefully recognize when the number pad (port extender) is disconnected?

Went ahead and ordered two Teensy 2.0 boards. A Teensy 2.0++ wouldn't really do me all that much use, as I'd need to feed something like 11-12 wires to an external number pad to use it in that manner. It makes far more sense to use a port extender, like how it's done in the Ergodox. Then you can just use a a four conductor cable (like a phone cord or a TRS connector with an extra ring) and communicate with I2C.

Now, speaking of that... I've seen some people use the MCP23017 and others use the MCP23018.They seem rather similar. One appears to be strictly open drain output on the GPIO, one seems to have more I2C address configurations. Is there a preference among the community, or a preferred chip for use with the firmware? I'd love to get it ordered at some point, even if I don't use it right away. Is the Teensy software written to prefer one or the other. Also, how does the Teensy handle hot swapping on the I2C. Can the firmware be configured to gracefully recognize when the number pad (port extender) is disconnected?

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Got the wood trim cut and pre assembled. I'll be taking it back off to make the USB opening, as well as the port for the number pad attachment point. The wood is oak... and was a pain to cut and file. everything was done with a hand saw and a hand file. Used a dremel to pre-drill the holes for the brass screws.

There's plenty room in the back for the teensy to just simply sit beneath the switches.

The keyboard is built at a slight angle. The front trim is 1/4 inch thick, and the back is 1/2 inch thick. (6.35 mm in front, 12.7 mm in back)

With the plate included, the current thickness of the front edge is 0.3 inches (7.62 mm). I'm sure a little thickness will be added with the bottom plate. I'm considering some thin copper or brass sheet for the bottom plate. I'll need a plastic insulator to shield the switches. If the copper or brass proves to be too stupidly expensive, I'll just probably cut out a steel plate from the side of a PC case or something.

There's plenty room in the back for the teensy to just simply sit beneath the switches.

The keyboard is built at a slight angle. The front trim is 1/4 inch thick, and the back is 1/2 inch thick. (6.35 mm in front, 12.7 mm in back)

With the plate included, the current thickness of the front edge is 0.3 inches (7.62 mm). I'm sure a little thickness will be added with the bottom plate. I'm considering some thin copper or brass sheet for the bottom plate. I'll need a plastic insulator to shield the switches. If the copper or brass proves to be too stupidly expensive, I'll just probably cut out a steel plate from the side of a PC case or something.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

I got the MagSafe connector fitted into the side frame of my keyboard. I have not finished the frame parts for the number pad yet... It got late, didn't wanna disturb the neighbors with late night sawing and drilling and filing... I might have thought about it though...

Pics should be self explanatory. I have not re-stained any of the cut areas of the wood, so ignore the lighter color, for now. The magnetic receptacle and the magnets are both fitted. The MagSafe receptacle sits slightly inset, with the contact plate being flush with the edge of the wood. On the number pad, the steel rimmed plug segment will protrude just slightly from the edge of the number pad frame, and will slightly insert into the side of the keyboard. The magnets on the number pad side will also slightly protrude, to form a positive mechanical lock when the two separate halves are fitted together.

I'll pick up some 5 minute epoxy from the store tomorrow, to set the magnets and connectors permanently. I might try to use a thin bead of wood glue around the seam of the MagSafe receptacle, since good wood glue accepts wood stain, and I can basically fill in the gaps around the connector. My cuts were not... ideal... Anyway, close enough. I can work with what I have, and the gap is still technically tight enough to hold the connector in place without the epoxy applied yet. Oak is a pain to work with, and I ain't redoing that piece! LOL ◴‿◶

Got the notice that Signature Plastics has shipped the Danger Zone keycaps to Massdrop, and they should have them by the end of the week. I'm so excited! My first custom keyboard is a mere couple weeks to completion! Anyway, I've "ejected" the Commodore 64 keys. Watch that canopy! It was a cool novelty, and useful for testing the feel of the keyboard, but we all know what keys are really intended for this keyboard...

It was a cool novelty, and useful for testing the feel of the keyboard, but we all know what keys are really intended for this keyboard...

So, I have pics, enjoy the build progress so far.

Pics should be self explanatory. I have not re-stained any of the cut areas of the wood, so ignore the lighter color, for now. The magnetic receptacle and the magnets are both fitted. The MagSafe receptacle sits slightly inset, with the contact plate being flush with the edge of the wood. On the number pad, the steel rimmed plug segment will protrude just slightly from the edge of the number pad frame, and will slightly insert into the side of the keyboard. The magnets on the number pad side will also slightly protrude, to form a positive mechanical lock when the two separate halves are fitted together.

I'll pick up some 5 minute epoxy from the store tomorrow, to set the magnets and connectors permanently. I might try to use a thin bead of wood glue around the seam of the MagSafe receptacle, since good wood glue accepts wood stain, and I can basically fill in the gaps around the connector. My cuts were not... ideal... Anyway, close enough. I can work with what I have, and the gap is still technically tight enough to hold the connector in place without the epoxy applied yet. Oak is a pain to work with, and I ain't redoing that piece! LOL ◴‿◶

Got the notice that Signature Plastics has shipped the Danger Zone keycaps to Massdrop, and they should have them by the end of the week. I'm so excited! My first custom keyboard is a mere couple weeks to completion! Anyway, I've "ejected" the Commodore 64 keys. Watch that canopy!

So, I have pics, enjoy the build progress so far.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Ah... I see I never actually posted that detail here! LOL... Hold on, copy paste time... I had posted the following over at Massdrop, but forgot to mention it here. Oops!

As an update to my own project, I ordered some parts from an Apple MagSafe 2 magnetic quick disconnect connector, and some additional magnets. I'm gonna mount them in the side of my keyboard, so I can create a magnetically detachable number pad, sometime in the future. Checked the clearances, and the MagSafe 2 connector should just fit, and my additional magnets are only 4mm in diameter, but are 6mm deep, and the strongest rating for their strength. I figure a pair of magnets and the MagSafe2 connector ought to keep a number pad firmly attached. My connections will feature Power, Ground, Rx, Tx, and Sense. Sense is just a simple signal that will indicate the presence of an accessory to the controller. Rx and Tx are the I2C communication lines, and the Power and Ground are to power the port extender that would be in the number pad to create the matrix for it. I realized I could use the unused keys of my keyboard matrix as sense detection. I just need to have the sense pin activate a transistor that connects a row and column together. The software would see the keypress as meaning a number pad is present, and to scan for the port expander.

NO idea how to implement that functionality in code though. I don't even have number pad plates, so I ain't TOO worried about number pad functionality just yet. For now, I just wanna get the ports installed, so I can add the functionality by software in the future, should I build it.

As an update to my own project, I ordered some parts from an Apple MagSafe 2 magnetic quick disconnect connector, and some additional magnets. I'm gonna mount them in the side of my keyboard, so I can create a magnetically detachable number pad, sometime in the future. Checked the clearances, and the MagSafe 2 connector should just fit, and my additional magnets are only 4mm in diameter, but are 6mm deep, and the strongest rating for their strength. I figure a pair of magnets and the MagSafe2 connector ought to keep a number pad firmly attached. My connections will feature Power, Ground, Rx, Tx, and Sense. Sense is just a simple signal that will indicate the presence of an accessory to the controller. Rx and Tx are the I2C communication lines, and the Power and Ground are to power the port extender that would be in the number pad to create the matrix for it. I realized I could use the unused keys of my keyboard matrix as sense detection. I just need to have the sense pin activate a transistor that connects a row and column together. The software would see the keypress as meaning a number pad is present, and to scan for the port expander.

NO idea how to implement that functionality in code though. I don't even have number pad plates, so I ain't TOO worried about number pad functionality just yet. For now, I just wanna get the ports installed, so I can add the functionality by software in the future, should I build it.

- Plasmodium

- Location: UK

- Main keyboard: QPAD MK80

- Main mouse: Logitech LX3

- Favorite switch: Cherry brown

- DT Pro Member: -

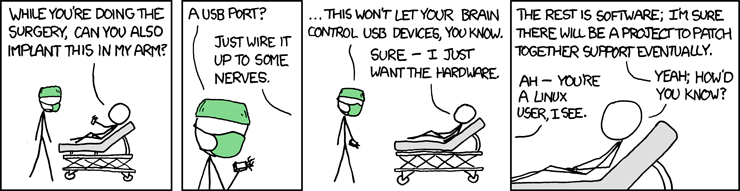

That reminds me of this:

You have the hardware, which is what matters - the software will come later.

Seriously, though, this project is awesome. I love the idea of a magnetic detachable numpad. I'm doing a 60% and extended numpad, but I went for the easy route and just have the numpad as a second 'keyboard' with a second controller.

-

Matt_

- Location: France

- Main keyboard: KBT Pure Pro

- Main mouse: G500

- Favorite switch: MX Red, MX Blue

- DT Pro Member: -

Maybe you can use the Ergodox fork of TMK as a basis? Extend the matrix connected to the Teensy and keep the MCP23018 code for the numpad.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Yeah. The thing i don't know, is how the software handles the removal of the MCP23018, and subsequent reattachment. Does the software misbehave if the chip is not on the I2C bus then expected, if the chip is removed, does it interfere with operation, and can it be reattached. I basically need hot swap functionality, and am unsure if the software will support that without altering.

Also, is there any preference between the MCP23017 and the open drain MCP23018. Noticed you mentioned the latter. Is there a fundamental benefit to going with open drain I/O in keyboard making, or is it just cheaper?

Also, is there any preference between the MCP23017 and the open drain MCP23018. Noticed you mentioned the latter. Is there a fundamental benefit to going with open drain I/O in keyboard making, or is it just cheaper?

- TuxKey

- LLAP

- Location: Netherlands

- Main keyboard: Leopold FC660C, Leopold FC660M mx-clears

- Main mouse: Apple Magic Trackpad, ducky Secret (PBT mouse)

- Favorite switch: Cherry MX-clear, Topre 45gr/55gr

- DT Pro Member: 0137

Awesome thread

i read your previous mention of this layout and really liked it

So much so that i saved a pic minus the F-row so it would be my favourite layout all time I tried 75% keyboards like the 75% race2 from kbparadise but i really really disliked the little right shift key..

I tried 75% keyboards like the 75% race2 from kbparadise but i really really disliked the little right shift key..

And having both FC660C/M models i really understand you layout decision.. pretty awesome layout

Being a OSX and Linux user i can dig the modifier row flexibility..

If i may be so bold i prefer this layout ofer the WhiteFox and the K-type (sorry matt3o & HaaTa)

Your A:B:C reasoning not only sounds like music to my ears

But belong inside the Vulcan handbook for logical thinking /reasoning !!

Alas i don't feel as comfortable soldering like you do..so unless you decide to start a project with them..

This level of DIY will have to wait a couple of years :crying:

Thx for the read...now back to my studies..

i read your previous mention of this layout and really liked it

So much so that i saved a pic minus the F-row so it would be my favourite layout all time

And having both FC660C/M models i really understand you layout decision.. pretty awesome layout

Being a OSX and Linux user i can dig the modifier row flexibility..

If i may be so bold i prefer this layout ofer the WhiteFox and the K-type (sorry matt3o & HaaTa)

Your A:B:C reasoning not only sounds like music to my ears

But belong inside the Vulcan handbook for logical thinking /reasoning !!

Alas i don't feel as comfortable soldering like you do..so unless you decide to start a project with them..

This level of DIY will have to wait a couple of years :crying:

Thx for the read...now back to my studies..

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

I have to say, I actually like that too! I actually use my F row enough to not have omitted it from this build, but I'm planning an eventual build of an Apple //c keyboard (with Alps Amber clicky switches) that will have bluetooth. Seems there's still some work to do before easy bluetooth is a thing. I'll wait. The //c isn't as nice a layout as this, but it has mods on the left, arrows (arranged linearly) to the right, no F row, but a few push to toggle switches up top. I'm planning for one to be power, and the other to toggle the top row between the number row and the F row. Maybe I'll have it toggle the arrows to be navigation keys too. I dunno. Haven't gotten that far yet!

Fascinating. The response to this particular input device configuration appears to be quite positive. The repeated statements of accolade, given by various users, would suggest that my current development direction for this device will prove to be quite fruitful.TuxKey wrote: I tried 75% keyboards like the 75% race2 from kbparadise but i really really disliked the little right shift key..

And having both FC660C/M models i really understand you layout decision.. pretty awesome layout

Being a OSX and Linux user i can dig the modifier row flexibility..

If i may be so bold i prefer this layout ofer the WhiteFox and the K-type (sorry matt3o & HaaTa)

Your A:B:C reasoning not only sounds like music to my ears

But belong inside the Vulcan handbook for logical thinking /reasoning !!

Well, Once this is up and running, maybe a PC board needs to be developed for this. I DO have a second plate like this one (anodized black, instead of blue) that I want to use for a "Typewriter" themed build, someday. A PC board would certainly be nice to have for that one, if anything, for the convenience.

I could even imagine the top row being designed to be cuttable... basically, the ability to remove the top row without interfering with the remainder of the board.

I've been calling this a 75% + 1 (Literally, a 75%, plus one additional column). I've heard others call it a 76% before. I'm not opposed to that. If a PC board had a break away/cuttable top row, you could theoretically have a single board that could serve as a 66%/76% PCB for layouts like mine and your F row-less alteration. If the right most column also were cuttable, then you could have a single PC board that could serve 65%, 66%, 75%, and 76% layouts. The key to those types of flexible layouts, is to have no part of the power, core 65% matrix, or controller outside the cut lines. Only the extra rows and column wiring crosses the cut line, and nothing would require continuity passed the cut to function on the inside section.

I'm actually an old hand routing pro. I built 2 PCBs in a day (after designing the circuit in a night) to create a walking robot using only 16 CMOS 74-series logic chips. Heck, I FORGOT how my design worked after the all nighter that brewed it, and it took me 3 days to decipher it!

The problem, is I've ALWAYS been a pen and paper kinda guy. I'm OLD school. Never learned how to really use CAD. I've tried a couple times... always revert to ink. I still make my own PC boards even! Got a tub of Ferric Chloride etchant in my bathroom! LOL

A keyboard layout like this REALLY needs to be done on a computer. Who knows. Maybe I can force myself to learn KiCAD or something.

Last edited by richfiles on 08 May 2017, 06:40, edited 2 times in total.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

I've actually considered that. I mention the MCP23018 in an earlier comment.Matt_ wrote: Maybe you can use the Ergodox fork of TMK as a basis? Extend the matrix connected to the Teensy and keep the MCP23018 code for the numpad.

My question, as I have never worked with this type of firmware before, is how does it handle hot swapping of the port expander not he I2C bus? Does it ignore the lack of a chip, if it's disconnected, does it experience an error, does it detect the presence (or lack thereof) of the chip?

Basically, I need it to be hot swappable. I need to be able to disconnect and connect the port expander at will, thanks to the magnetically detachable nature of the number pad. Can the firmware support this? If so, then I'm already set. I just need to do as you say, and work with a variant of that firmware.

I also have another question...

I use a Mac... Well, a home made "hackintosh". I ain't paying Apple those prices! LOL Is it possible to have a keyboard send a unicode character, not int he standard character set typical of your average keyboard? I know Macs support an input layout that can accept unicode input, but that hijacks the Option (alt) key, and disables the natural third and fourth keyboard character sets (Option and Shift+Option). Those are PROGRAMMED into me, and I hate the idea of losing that functionality... ⤳⁔⤺

Which is why I ask... Can a keyboard firmware be programmed to send specific unicode characters as part of the HID protocol? ◔ᴗ◔

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Well, the MagSafe based number pad attachment has been completed. It comes together with a solid snap! I'll be setting the number pad frame parts aside, till I can get a plate made for the number pad. I can now reassemble the frame to my keyboard, and once wired in, I'll be ready for a number pad upgrade whenever I have the opportunity to build it.

https://www.youtube.com/watch?v=YFRzutJ8VVA

The magnets are inset on the keyboard, and protrude slightly on the number pad side. This helps create a positive lock and keeps everything nicely aligned. The connector on the keyboard is flush, but the magnetic portion is inset. The steel shroud on the number pad side slightly protrudes, surrounding the contacts, and fitting into the inset portion of the keyboard side of the connector. That definitely helps with alignment.

The most important part... It passes continuity tests. None of the 5 pins are electrically shorted to one another, and I have proper conduction from one connector to the mated connector. It is ready for installation!

https://www.youtube.com/watch?v=YFRzutJ8VVA

The magnets are inset on the keyboard, and protrude slightly on the number pad side. This helps create a positive lock and keeps everything nicely aligned. The connector on the keyboard is flush, but the magnetic portion is inset. The steel shroud on the number pad side slightly protrudes, surrounding the contacts, and fitting into the inset portion of the keyboard side of the connector. That definitely helps with alignment.

The most important part... It passes continuity tests. None of the 5 pins are electrically shorted to one another, and I have proper conduction from one connector to the mated connector. It is ready for installation!

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Doesn't it kinda look like the handle of a steak knife?

Got the part mounted. Just enough clearance to clear the wires. Too tired after work to solder it today... Work was easy... Stupid Fallout 4 kept me up late!

It fits NIIIIICE!!! It self aligns nicely, as well.

Bit of a set back... Minor, and VERY stupid, but it probably means ordering more parts or potentially not having it done when the caps show up... Ordered a small Mini-B USB breakout board from Amazon. See today it shipped by... Royal Mail? What? I'm in the US! OH, COME ON! Amazon, you had one job! I go out of my way to find a seller that doesn't appear to be Chinese, and what do they do? Amazon goes and ships from the UK, my kinda time sensitive IMPORTANT BIT that connects my no cheetos clickety clacker to my Kerbal Up Goer simulator box. Really...

I may just re-order... of course, I can't find another breakout this small. Go FIGURE... Amazon, I am disappoint.

Got the part mounted. Just enough clearance to clear the wires. Too tired after work to solder it today... Work was easy... Stupid Fallout 4 kept me up late!

It fits NIIIIICE!!! It self aligns nicely, as well.

Bit of a set back... Minor, and VERY stupid, but it probably means ordering more parts or potentially not having it done when the caps show up... Ordered a small Mini-B USB breakout board from Amazon. See today it shipped by... Royal Mail? What? I'm in the US! OH, COME ON! Amazon, you had one job! I go out of my way to find a seller that doesn't appear to be Chinese, and what do they do? Amazon goes and ships from the UK, my kinda time sensitive IMPORTANT BIT that connects my no cheetos clickety clacker to my Kerbal Up Goer simulator box. Really...

I may just re-order... of course, I can't find another breakout this small. Go FIGURE... Amazon, I am disappoint.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Well... Very good news... and VERY bad news.

First, the Good news. I think I've found my bottom plate. I was going through my storage unit and found an old piece of rack mount test equipment from the 1960s (A Phase Angle Voltmeter, for the sakes of useless trivia). Had an aluminum cover panel with a laminated plastic layer that has a faux "leather" like texture to it... BINGO! That's the bottom!

I'll cut two pieces, one for the keyboard, and one for the as of yet nonexistent, but planned number pad (maybe just a wide piece I can trim to specific size later). It even has a paint coat on the inside, so it SHOULD be insulated from contact with the switch matrix, even if it were pressed inward, but I'll still drop in a sheet of plastic as an internal insulator. It's really thin... 1.1mm (.043 inch), and I can punch a nice countersunk hole for each screw. I'll get wood screws for the bottom, that'll go in flush. That way, I'll only add a hair over 1 mm to the thickness once I add the bottom plate.

Now for the bad news...

I was casually looking at keyboard stuff, and came across this HORRIFYING picture...

Oh, say it ain't so! When I was FIRST doing this layout, I mentioned (back on page 22 of the Massdrop Danger Zone discussions pages) that I wanted to use the stepped caps lock, and asked if the stem position was centered...

https://www.massdrop.com/buy/danger-zon ... alk/277804

"Also, is the stem on the caps lock key centered with no stabilizer? I intend to use the stepped caps lock key. The plate was generated based on the stock Keycool 84 layout, with my modifications performed to it. I don't wanna order a plate and find the caps lock key is wrong."

I was told it was fine, but having seen that picture, doubts were raised. I didn't know if it REALLY was fine or not? The comment that said it was fine never actually mentioned the Caps Lock, just said the layout was fine. I didn't remember if I knew how to do stepped keys in the layout editor back then, and got terribly worried that now, that this close to the finish line, I might have screwed up. The example pic from the layout editor back then had a standard Caps Lock key shown, even though I mentioned wanting to use the stepped cap. If I had submitted that DXF file for the plate manufacturing... Dang it... This is bad...

I really hate the thought of not being able to use my stepped Caps Lock on this thing...

So, I checked it... DANG IT! I've confirmed it... my plates are wrong

I re-ran my current keyboard layout through the plate builder, and the Caps Lock switch is offset to the left of the tab switch, when a stepped Caps Lock is indicated from the Keyboard Layout editor.

My plates have the Caps lock offset slightly right of the Tab switch. ╱)⤳⁔⤺(╲

Does someone actually KNOW what the exact distance of offset is? Looks like the only way i'm getting a stepped Caps Lock is to grab a file and mar up my pretty little anodized plates to make this work. I'll have to cut a filler and epoxy it into the gap left by widening the switch opening in the plate.

First, the Good news. I think I've found my bottom plate. I was going through my storage unit and found an old piece of rack mount test equipment from the 1960s (A Phase Angle Voltmeter, for the sakes of useless trivia). Had an aluminum cover panel with a laminated plastic layer that has a faux "leather" like texture to it... BINGO! That's the bottom!

I'll cut two pieces, one for the keyboard, and one for the as of yet nonexistent, but planned number pad (maybe just a wide piece I can trim to specific size later). It even has a paint coat on the inside, so it SHOULD be insulated from contact with the switch matrix, even if it were pressed inward, but I'll still drop in a sheet of plastic as an internal insulator. It's really thin... 1.1mm (.043 inch), and I can punch a nice countersunk hole for each screw. I'll get wood screws for the bottom, that'll go in flush. That way, I'll only add a hair over 1 mm to the thickness once I add the bottom plate.

Now for the bad news...

I was casually looking at keyboard stuff, and came across this HORRIFYING picture...

Oh, say it ain't so! When I was FIRST doing this layout, I mentioned (back on page 22 of the Massdrop Danger Zone discussions pages) that I wanted to use the stepped caps lock, and asked if the stem position was centered...

https://www.massdrop.com/buy/danger-zon ... alk/277804

"Also, is the stem on the caps lock key centered with no stabilizer? I intend to use the stepped caps lock key. The plate was generated based on the stock Keycool 84 layout, with my modifications performed to it. I don't wanna order a plate and find the caps lock key is wrong."

I was told it was fine, but having seen that picture, doubts were raised. I didn't know if it REALLY was fine or not? The comment that said it was fine never actually mentioned the Caps Lock, just said the layout was fine. I didn't remember if I knew how to do stepped keys in the layout editor back then, and got terribly worried that now, that this close to the finish line, I might have screwed up. The example pic from the layout editor back then had a standard Caps Lock key shown, even though I mentioned wanting to use the stepped cap. If I had submitted that DXF file for the plate manufacturing... Dang it... This is bad...

I really hate the thought of not being able to use my stepped Caps Lock on this thing...

So, I checked it... DANG IT! I've confirmed it... my plates are wrong

I re-ran my current keyboard layout through the plate builder, and the Caps Lock switch is offset to the left of the tab switch, when a stepped Caps Lock is indicated from the Keyboard Layout editor.

My plates have the Caps lock offset slightly right of the Tab switch. ╱)⤳⁔⤺(╲

Does someone actually KNOW what the exact distance of offset is? Looks like the only way i'm getting a stepped Caps Lock is to grab a file and mar up my pretty little anodized plates to make this work. I'll have to cut a filler and epoxy it into the gap left by widening the switch opening in the plate.

-

Matt_

- Location: France

- Main keyboard: KBT Pure Pro

- Main mouse: G500

- Favorite switch: MX Red, MX Blue

- DT Pro Member: -

You'll have to offset your hole by 4.76 mm to the left in order to use your stepped capslock.

That's a bummer, but you should be able to correct it. File down the left side of the opening (put masking tape on your plate in order to avoid scratching it), then glue a 4.7mm wide piece of something (possibly with a larger piece of something under the plate to support it) to prevent the switch from moving laterally. Good luck!

That's a bummer, but you should be able to correct it. File down the left side of the opening (put masking tape on your plate in order to avoid scratching it), then glue a 4.7mm wide piece of something (possibly with a larger piece of something under the plate to support it) to prevent the switch from moving laterally. Good luck!

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Thanks for the quick info. I might give it a shot Sunday... Next day off.

I may try to turn this to my advantage. My original plan was to drill a hole in the stepped area of the caps lock key and mount a light pipe to redirect the light from the MX LED to the hole, as a caps lock indicator. I realize I can do it even easier now. If I can do it right, I'll drill my hole, and glue a tube to the hole, to make the light off. The tube will pass through a hole in the filler piece, and my LED will be below the plate.

I got some blue model paint too, so I can get it "close enough" to the color of the plate.

It might almost look intentional...

I may try to turn this to my advantage. My original plan was to drill a hole in the stepped area of the caps lock key and mount a light pipe to redirect the light from the MX LED to the hole, as a caps lock indicator. I realize I can do it even easier now. If I can do it right, I'll drill my hole, and glue a tube to the hole, to make the light off. The tube will pass through a hole in the filler piece, and my LED will be below the plate.

I got some blue model paint too, so I can get it "close enough" to the color of the plate.

It might almost look intentional...

- TuxKey

- LLAP

- Location: Netherlands

- Main keyboard: Leopold FC660C, Leopold FC660M mx-clears

- Main mouse: Apple Magic Trackpad, ducky Secret (PBT mouse)

- Favorite switch: Cherry MX-clear, Topre 45gr/55gr

- DT Pro Member: 0137

WOW how awesome would that be and not to mention innovative on a grand scale..Somthing that has never been done before..richfiles wrote:

If a PC board had a break away/cuttable top row, you could theoretically have a single board that could serve as a 66%/76% PCB for layouts like mine and your F row-less alteration. If the right most column also were cuttable, then you could have a single PC board that could serve 65%, 66%, 75%, and 76% layouts. The key to those types of flexible layouts, is to have no part of the power, core 65% matrix, or controller outside the cut lines. Only the extra rows and column wiring crosses the cut line, and nothing would require continuity passed the cut to function on the inside section.

A detachable keyboard from 65%, 66%, 75%, and 76%

That would really be something to buy....

although i find your 75%+1 with all default keycap size..And compact board to be one of the most innovative designs in a long time..

Lets hope we normal mortals can get our hands on one..preferably from a EU location..i don't fancy paying 33% extra on every single thing i buy

Nice job on the Hackintosh i have a mid 2012 Macbook Pro 15-inch non retina matt display because i could add 1 or two ssd's if i wanted to ..but my next computer will be a Linux build ..

show us the final build..perhaps sum youtube TLC

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

I like the idea of flexible PCBs (not to be confused with flex PCBs  ) because you can manufacture one part to serve multiple end uses. Even if you're ordering a slightly bigger PCB, the fact that 4 different groups could effectively buy it, means 4x quantity, and quantity is the key to low cost in manufacturing. It's why group buys and Massdrop are a thing.

) because you can manufacture one part to serve multiple end uses. Even if you're ordering a slightly bigger PCB, the fact that 4 different groups could effectively buy it, means 4x quantity, and quantity is the key to low cost in manufacturing. It's why group buys and Massdrop are a thing.

I honestly wish I did have a PCB designed for this thing, but alas... I do not...

Even though this Cap Lock thing is gonna be a huge hassle, it affords me the opportunity to do something apart of the fix itself... Pic should explain all. I'll be using the filler piece to serve as a hole for a shroud to pass through. Beneath the plate, will be an LED to illuminate Caps Lock state. When life gives you lemons... You can either make lemonade or quote Cave Johnson!

I honestly wish I did have a PCB designed for this thing, but alas... I do not...

Even though this Cap Lock thing is gonna be a huge hassle, it affords me the opportunity to do something apart of the fix itself... Pic should explain all. I'll be using the filler piece to serve as a hole for a shroud to pass through. Beneath the plate, will be an LED to illuminate Caps Lock state. When life gives you lemons... You can either make lemonade or quote Cave Johnson!

- Corummo

- Location: Italy

- Main keyboard: Coolermaster Quickfire Ultimate

- Main mouse: Logitech MX310

- Favorite switch: Cherry MX Brown

- DT Pro Member: -

- Contact:

I'm amazed by your crafting skills.richfiles wrote: Even though this Cap Lock thing is gonna be a huge hassle, it affords me the opportunity to do something apart of the fix itself... Pic should explain all. I'll be using the filler piece to serve as a hole for a shroud to pass through. Beneath the plate, will be an LED to illuminate Caps Lock state. When life gives you lemons... You can either make lemonade or quote Cave Johnson!

Your wiring is the most polished one I've ever seen.

Kudos to you and, well, I subscribed to watch further developments of your interesting build.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

I've been looking into things, and it seems that there is already a documented stem modification for making a stepped caps lock fit a keyboard designed for a full caps lock. I think I'd rather give that a shot, than start hacking up my plate. There are gracious people who have already offered their Danger Zone stepped Caps Lock key (since some keyboards just don't use it), so even if I dont get the key cap mod right initially, I DO have backup options if I go that route.

Still gonna mod the key with a lighted window to indicate if caps is locked or not.

I have also been considering underlighting. I can't say I've really been a fan of it in the past, but I can see the value in acti g as a homing guide when ambient lighting is otherwise low or off. I have found some amber LEDs, that while not as cheap as I would care for, will arrive shiped in 2-3 days (local company). Still have not decided if I will dimly illuminate all switches, or just get the borders. Since I have no PC board, LEDs would be a potential problem. If I habd wire them, I prevent the top housing from being removable.

Do the tiny SIP sockets that people use for LEDs fit inside the lower housing, under the LED? Never tried. I could hand wire SIP sockets in, if that indeed works, then I'll be okay.

Still gonna mod the key with a lighted window to indicate if caps is locked or not.

I have also been considering underlighting. I can't say I've really been a fan of it in the past, but I can see the value in acti g as a homing guide when ambient lighting is otherwise low or off. I have found some amber LEDs, that while not as cheap as I would care for, will arrive shiped in 2-3 days (local company). Still have not decided if I will dimly illuminate all switches, or just get the borders. Since I have no PC board, LEDs would be a potential problem. If I habd wire them, I prevent the top housing from being removable.

Do the tiny SIP sockets that people use for LEDs fit inside the lower housing, under the LED? Never tried. I could hand wire SIP sockets in, if that indeed works, then I'll be okay.

-

Matt_

- Location: France

- Main keyboard: KBT Pure Pro

- Main mouse: G500

- Favorite switch: MX Red, MX Blue

- DT Pro Member: -

Yes, SIP sockets fit inside the switch and won't prevent you from removing the top. However, you'll probably need a PCB to keep them in place — hand-wiring them would be a nightmare.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

The plastic used by Gateron seems to be relatively thermally resistant. If I use my wire wrap tool, I can basically create a "bead" of wire + solder at the base of each. I think that could work, and I've gotten proficcient enough with wire wrapping, that lately, I find PCBs to be too much of a hassle to bother to make, though I still do wish I had one for this keyboard.

...

Or, as I realize, I have piles of cheap Chinese PC proto board. I could literally just cut squares of it out, just to act as a solderable backing to hold the pins. Either way, I should be okay.

...

Or, as I realize, I have piles of cheap Chinese PC proto board. I could literally just cut squares of it out, just to act as a solderable backing to hold the pins. Either way, I should be okay.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Well, good news!

The keys SHIPPED! I have an active UPS tracking number that shows delivery by next Wednesday (17th).

Seeing as how it's UPS SurePost... I expect the 18th instead. I think I'll instruct them to hold it at the post office and pick it up in person.

The keys SHIPPED! I have an active UPS tracking number that shows delivery by next Wednesday (17th).

Seeing as how it's UPS SurePost... I expect the 18th instead. I think I'll instruct them to hold it at the post office and pick it up in person.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Okay. I have a software question. I have asked it before, and I have not gotten an answer. This is one for those who have built keyboards using port expanders.

Does the keybiard firmware typically available support graceful removal/detection of the port expander frim the I2C bus?

Does the keybiard firmware typically available support graceful removal/detection of the port expander frim the I2C bus?

-

Matt_

- Location: France

- Main keyboard: KBT Pure Pro

- Main mouse: G500

- Favorite switch: MX Red, MX Blue

- DT Pro Member: -

I have no firsthand experience with that, but it looks like the original Ergodox (with port expander & halves linked by a TRRS cable) does not support hot-plugging: https://geekhack.org/index.php?topic=69512.0

Apparently that's a firmware limitation. On the other hand I've always read advice like "never hot-plug this or that, but if you have to, always connect gnd first and then vcc, and disconnect vcc first and then gnd", so hot-plugging chips is something I'm a bit weary of for electrical reasons. But then again, I never tried that myself.

Apparently that's a firmware limitation. On the other hand I've always read advice like "never hot-plug this or that, but if you have to, always connect gnd first and then vcc, and disconnect vcc first and then gnd", so hot-plugging chips is something I'm a bit weary of for electrical reasons. But then again, I never tried that myself.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

Ugh... I'll have to figure out that part of the code myself then... Awesome... My noob™ skills will make programming support for my number pad... Well, it'll be a while...

Hot plugging isn't an issue, in terms of electrical. All that stuff can be easily managed with good design. That link you provided actually had the guy doing the plugging, using the wrong type of cable. Not to mention, a TRS or TRSS cable is a horrible thing that is begging to cause hot swapping trouble. It's why my connector is a parallel connection configuration, known for it's hot swappability. If you look closely, it even has a pair of pogos raised higher than the rest, specifically for the purpose of first contact/break. It's the software's awareness of the event. Will the software lockup if it gets no data from a port expander (that's not hooked up), or will the software ignore it till it actually receives a packet of data. Do I need to actively toggle two software modes by way of my sense pin (which I included, assuming I'd need to do that).

I'll have to ask the dude who did the one hand how he does it. I know he's using a micro in both halves, but he also has the ability to do chording on one hand with one unit, or to have it automatically switch to two hand mode (split 40%) when a second unit is plugged in. At the moment,t he software exceeds my skill level. Mostly, any software that isn't "put in your key matrix here, compile, and you're good" is probably above my level. I am SO a hardware guy.

Software is the homework of tinkering.

Hot plugging isn't an issue, in terms of electrical. All that stuff can be easily managed with good design. That link you provided actually had the guy doing the plugging, using the wrong type of cable. Not to mention, a TRS or TRSS cable is a horrible thing that is begging to cause hot swapping trouble. It's why my connector is a parallel connection configuration, known for it's hot swappability. If you look closely, it even has a pair of pogos raised higher than the rest, specifically for the purpose of first contact/break. It's the software's awareness of the event. Will the software lockup if it gets no data from a port expander (that's not hooked up), or will the software ignore it till it actually receives a packet of data. Do I need to actively toggle two software modes by way of my sense pin (which I included, assuming I'd need to do that).

I'll have to ask the dude who did the one hand how he does it. I know he's using a micro in both halves, but he also has the ability to do chording on one hand with one unit, or to have it automatically switch to two hand mode (split 40%) when a second unit is plugged in. At the moment,t he software exceeds my skill level. Mostly, any software that isn't "put in your key matrix here, compile, and you're good" is probably above my level. I am SO a hardware guy.

Software is the homework of tinkering.

- richfiles

- Location: MN, USA

- Main keyboard: Logitech DiNovo Edge

- Main mouse: Microsoft Optical Notebook Mouse

- Favorite switch: Alps SKCM Amber "Taxi Yellow"

- DT Pro Member: -

I'm so jealous of all these keys that are showing up already! LOL

I still gotta wait till Wednesday for mine!

I did ultimately decide to go ahead and install LEDs in all the switches, not just select ones. I'm aiming for VERY dim lighting, so I used diffused 12 mcd amber LEDs. The intent is to mimic the low intensity instrument panel lighting of aircraft panels.

I also got more stoopid™ news. My SIP sockets and LEDs won't show up until Tuesday, cause Monday is a US holiday, and no mail service will run that day. I happen to have Monday off... And not the last parts I need... Parts LITERALLY sitting 5 minutes away from my home in a closed post office. Tracking SAYS SO! Ugh... Such a tease! REALLY wish these parts weren't taking forever! Basically, I'll have a single afternoon, after work, to install all 88 SIP socket pairs and LEDs into the switches. Fun times.

I may actually desolder the SIP sockets from the LED display drivers for my Kerbal Space Program DSKY. I have to manually wire them onto the new larger LED display panel, and needed to remove them anyway. It turns out to be enough SIP sockets to do the whole keyboard. I'll still have to wait till Tuesday to plug the LEDs in though and test it.

At least I can FINALLY install my USB connector. Thing FINALLY arrived from the UK. I've already figured out how to install it securely. I'll use the dremel to cut a slot on the inside of the back trim panel for the PC board to slide into. I'll drill a large hole and file it rectangular for the USB plug to pass through, and I'll drill two small holes perpendicular to the PC board and lined up with the mounting holes to pass a pair of screws through. Since the PC board slot will be on the inside, I can get away with a crude cut. I just have to not cut through the wood completely. It won't be hard, thankfully. A small square of proto board soldered to the end of it, and the other end of the proto board soldered to the teensy will provide the anchor point I need to secure it safely.

I still gotta wait till Wednesday for mine!

I did ultimately decide to go ahead and install LEDs in all the switches, not just select ones. I'm aiming for VERY dim lighting, so I used diffused 12 mcd amber LEDs. The intent is to mimic the low intensity instrument panel lighting of aircraft panels.

I also got more stoopid™ news. My SIP sockets and LEDs won't show up until Tuesday, cause Monday is a US holiday, and no mail service will run that day. I happen to have Monday off... And not the last parts I need... Parts LITERALLY sitting 5 minutes away from my home in a closed post office. Tracking SAYS SO! Ugh... Such a tease! REALLY wish these parts weren't taking forever! Basically, I'll have a single afternoon, after work, to install all 88 SIP socket pairs and LEDs into the switches. Fun times.

I may actually desolder the SIP sockets from the LED display drivers for my Kerbal Space Program DSKY. I have to manually wire them onto the new larger LED display panel, and needed to remove them anyway. It turns out to be enough SIP sockets to do the whole keyboard. I'll still have to wait till Tuesday to plug the LEDs in though and test it.

At least I can FINALLY install my USB connector. Thing FINALLY arrived from the UK. I've already figured out how to install it securely. I'll use the dremel to cut a slot on the inside of the back trim panel for the PC board to slide into. I'll drill a large hole and file it rectangular for the USB plug to pass through, and I'll drill two small holes perpendicular to the PC board and lined up with the mounting holes to pass a pair of screws through. Since the PC board slot will be on the inside, I can get away with a crude cut. I just have to not cut through the wood completely. It won't be hard, thankfully. A small square of proto board soldered to the end of it, and the other end of the proto board soldered to the teensy will provide the anchor point I need to secure it safely.

-

Matt_

- Location: France

- Main keyboard: KBT Pure Pro

- Main mouse: G500

- Favorite switch: MX Red, MX Blue

- DT Pro Member: -

The brightness rating is not super important, you can always tone down brightness by feeding LEDs less current. Good idea to go with diffused LEDs though.

I'm curious to see the final result with sockets without a PCB. How are you going to wire LEDs?

I'm curious to see the final result with sockets without a PCB. How are you going to wire LEDs?