Sadly I never tried one

(Model MF) Remodeling the Model M (aka.. the Mara)

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

- vivalarevolución

- formerly prdlm2009

- Location: USA

- Main keyboard: IBM Beam spring

- Main mouse: Kangaroo

- Favorite switch: beam spring

- DT Pro Member: 0097

oh god, I stay off for a few days and this happens.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Typical, eh? Anyway, nothing to fear. You haven't missed the good bit yet.

Model M is a nice placeholder for where a Model F mechanism ought to be. Make it so!

Model M is a nice placeholder for where a Model F mechanism ought to be. Make it so!

- Touch_It

- Location: Nebraska, United States.

- Main keyboard: Unicomp Classic USB 103 key (work) IBM F 4704 107

- Main mouse: Logitech g502 Proteus Core

- Favorite switch: Buckling spring (yet to try Beam Spring)

- DT Pro Member: -

0100010 wrote:Where is the 103 key layout?

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

I'm happy to add any hole we like in the top plate (everything has been created in OpensCAD as a "barrel cutout" module, and adding another is literally just another point in the 2D array). We could make it look like "swiss cheese" (yanks), "Emmental"... and it will not impact anything structurally since the key spread to "cut-out" ratio is so vast, and we are dealing with curved steel of a reasonable thickness. I would promote the idea of a single top plate with polymer plugs/grommets/caps when a key isn't needed though to keep the PCB clean. It would be up to i$ to make sure there is a spot on the PCB ready to honor the barrel/flipper. My vote would be to do any desirable combination (single pcb/plate), and scale back as you need with 12mm caps covering exposed areas

Spoiler:

-

jacobolus

- Location: geekhack ergonomics subforum

- Favorite switch: Alps plate spring; clicky SMK

- DT Pro Member: -

-

jacobolus

- Location: geekhack ergonomics subforum

- Favorite switch: Alps plate spring; clicky SMK

- DT Pro Member: -

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

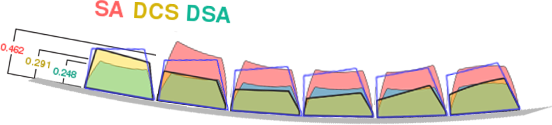

Ugh. No thanks! I'm thinking one of these:

workshop-f7/replacement-badge-for-f-upg ... 13800.html

Of course, I'm talking about an original SSK case. A metal beast… well… I'm as likely to plop a GH logo on that as I am an effigy of Ripster's arse. But there's potential for something special there!

Besides, I think DSA could be awesome on a curve!

Stabs will be the hard part. Buckling spring caps take an entirely different (asymmetrical) approach to sizes between 1.75 and 2.75 units. Quite how regular MX caps will go on those… it'll take a non-IBM compatible barrel layout for a start.

workshop-f7/replacement-badge-for-f-upg ... 13800.html

Of course, I'm talking about an original SSK case. A metal beast… well… I'm as likely to plop a GH logo on that as I am an effigy of Ripster's arse. But there's potential for something special there!

I'm intrigued by the MX caps side of this. Not enough to be thrown off the key objective: a drop in Model F kit! But once we reach that point, I'd want to see or try what the diagram presents with SA. I find that profile too flat for my liking on a flat backplate. Way too much gutter between the keytops. Experimentation seems a good idea. Even negative results say more than an opinion alone can provide.

Besides, I think DSA could be awesome on a curve!

Stabs will be the hard part. Buckling spring caps take an entirely different (asymmetrical) approach to sizes between 1.75 and 2.75 units. Quite how regular MX caps will go on those… it'll take a non-IBM compatible barrel layout for a start.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

You have just described my feelings 100% (I know that wasn't your intention, but I'm still tweeking out about it)Muirium wrote: I'm intrigued by the MX caps side of this. Not enough to be thrown off the key objective: a drop in Model F kit! But once we reach that point, I'd want to see or try what the diagram presents with SA. I find that profile too flat for my liking on a flat backplate. Way too much gutter between the keytops. Experimentation seems a good idea. Even negative results say more than an opinion alone can provide.

Besides, I think DSA could be awesome on a curve!

Stabs will be the hard part. Buckling spring caps take an entirely different (asymmetrical) approach to sizes between 1.75 and 2.75 units. Quite how regular MX caps will go on those… it'll take a non-IBM compatible barrel layout for a start.

The really important part to remember about all of this... We can do whatever we want. I REALLY want the stems to work for the original M for obvious reasons, but the silly Capslock (of all things) is the one that will be a bear. But if it doesn't work out for the full set, we make it work for our "future" board. If we can add split shifts and command keys, we can certain move Capslock 2mm... Then we know everything will work, and design stems appropriately (as few as possible to minimize costs).

On the curved plane part, the same applies... Dial the radial bend to the amount we think it's optimal for Cherry caps (something between 300mm and flat). But as you said, the curve in its current form might make DCS finally desirable to us. It is certainly more readily available anyway.

We are about to have some fun experiments, and you will get to weigh in with lots of opinions

EDIT: I love this badge too btw. I PM'd WCass yesterday with a crude mockup of having FEXT as a tilted subtitle in IBM font, and asked about a smaller one with FSSK... along with a square version of each (people might want the FEXT in a 1390131). Having it made from a PCB is storybook to me, since it was I$'s PCB that is making all of this possible. I am anxious to see the results from the GB

- bocahgundul

- Sell me 5k please

- Location: Indonesia

- Main keyboard: TGR Jane CE

- Main mouse: SS rival 300

- Favorite switch: Gateron

- DT Pro Member: -

Can you just take my money man? I FKIN LOVE 1 OF THESE!

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

If someone is an injection molding "expert", or knows someone with a little experience in this area, please either post here or PM me. I have access to a CNC machine for creating the aluminum molds themselves, and access to a 75 ton press when we are ready to give the ABS a go. In the meantime, I would like to start working out the layout of the molds (think surface area per ton since you want multiple parts from each press, etc). My metal fabrication knowledge is strong, but plastic extrusion is limited (other than a couple weeks of research), and I would prefer to show up somewhat "gathered" to each of these fabricator discussions to keep costs down.

I have sent the flipper off for FTIR testing to finally understand what they are REALLY made of. I know the conductive properties of the plastic flipper using reasonable equipment, but would like to get the exact polymer/ash/etc ratio if possible before proceeding.

I know Ellipse has worked up the following for the barrel and flipper in his F62/77 project:

Also, I would like to do all of this domestically (either the states or Europe). I would much rather spend 10 additional dollars per drop-in, and monitor the progress easily. I have spec'd out the springs, and the cost would be approximately .05 USD per spring (4.20 for an SSK and 5.05 for the 101 key, etc). The US based company providing this quote (I have used in my day job) is sending me a sample to test with.

Again... calling on injection molding experts. PM or post here. It's premature to think GB just yet, but we need to start getting our "ducks in a row" due to the number of parts and complication of all of this

I have sent the flipper off for FTIR testing to finally understand what they are REALLY made of. I know the conductive properties of the plastic flipper using reasonable equipment, but would like to get the exact polymer/ash/etc ratio if possible before proceeding.

I know Ellipse has worked up the following for the barrel and flipper in his F62/77 project:

- Barrel Material: ABS POLYLAC PA-757

- Flipper Material: Torayca ASHT-18A

Also, I would like to do all of this domestically (either the states or Europe). I would much rather spend 10 additional dollars per drop-in, and monitor the progress easily. I have spec'd out the springs, and the cost would be approximately .05 USD per spring (4.20 for an SSK and 5.05 for the 101 key, etc). The US based company providing this quote (I have used in my day job) is sending me a sample to test with.

Again... calling on injection molding experts. PM or post here. It's premature to think GB just yet, but we need to start getting our "ducks in a row" due to the number of parts and complication of all of this

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Status update...

Good news...

I would ask the following of everyone:

Good news...

- I did receive the metal plates from Big Blue Saw today, and they look really good.

- Over lunch, I debured the plates (there is always residue from any type of jetting process on the bottom layer, even with low-taper), and sprayed with an etching primer to let me handle them longer in flat form before "working the metal" later into our desired shape after "Cherry adapter flat plate" testing. They are drying now in the shop

- The Shapeways order for the modified stem adapters, with higher definition barrels and flippers (Acrylate this time), AND spacebar, are scheduled to ship at the tail end of this week.

- I have completed the FEXT design for the full 101-key with several renders to show, but will wait to post after verifying against i$'s tested PCB designs he agreed to post later this evening. I am curious what he is proposing for the LEDs since some of us will have the newer "membrane ribbon cable", and that will be less than trivial to interface with the xWhatsit headers. Also... There is SO much wasted room at the top of the 101-key Model M, it's nuts (I am sure they did for visual uniformity). So plan on a 101-key being MUCH smaller at the top if/when we do decide to make our own compact cases later.

- I will be traveling for work all of next week, and this is holiday weekend (I need one

). So any progress will need to be made prior to our US holiday (Memorial Day) weekend.

). So any progress will need to be made prior to our US holiday (Memorial Day) weekend.

I would ask the following of everyone:

- Figure out the desired key layout (every possible combination) for what we want going forward in both the SSK and full size model M versions. We have mentioned command keys and the like, but if someone could post "the perfect ELABORATE layout"... and have everyone nod "YES"... I would appreciate.

- I have already started communications with injection molding folks, but it will be a bit to get the "request for quote" (RFQ) back. In the meantime... what is everyone's stance on handling the barrels and flippers? Are you comfortable paying $1 USD per barrel/flipper combo (base SSK would cost $84, base full size is $101) from Ellipse... or do we need to get that cost down?!? I will take a firm stance that I don't want to see XT/Bigfoot parts salvaged (at least long term) for this project.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

I don't know if we can come up with one layout to rule them all.

My ideal FEXT layout is basically equivalent to the Unicomp 103, with 1x key positions between each 1.5x ctrl-alt pair. That would allow simply taking an existing IBM keycsp set and adding a couple more caps to round it out.

But if I'm coming from the angle of wanting to use adapters and MX caps (I'm still not sold on that idea, yet, until I actually see a prototype in action) then I'm going to want an FEXT in a modern 104 or even a 108 layout, with the 1.25x mods on the bottom row.

It's going to be a tough one to work out, because of the two types of customers for this mod. But I really appreciate

all the hard work you are putting into this, lot lizard!

My ideal FEXT layout is basically equivalent to the Unicomp 103, with 1x key positions between each 1.5x ctrl-alt pair. That would allow simply taking an existing IBM keycsp set and adding a couple more caps to round it out.

But if I'm coming from the angle of wanting to use adapters and MX caps (I'm still not sold on that idea, yet, until I actually see a prototype in action) then I'm going to want an FEXT in a modern 104 or even a 108 layout, with the 1.25x mods on the bottom row.

It's going to be a tough one to work out, because of the two types of customers for this mod. But I really appreciate

all the hard work you are putting into this, lot lizard!

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

You bring up a good point... And I should have qualified. I'm looking for the the most elaborate layout anyone would want with the DROP-IN replacement for now (including any existing Model M shell mods someone would be willing to make to accommodate). We will worry about the "pie in the sky" Cherry cap fluff later.

Assuming split shifts (both sides), ISO enter, and command/windows keys so far for anything we might actually produce as a drop-in. Are there more?. I would like to work in the designs earlier than later

Appreciate the feedback btw...

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

Okay, that makes a lot of sense. Talking drop-in replacement, IBM's barrel layout nicely accommodates almost every modern layout configuration just by adding/moving flippers and stabilizer inserts. I believe the FSSK/FEXT designs include pads under every barrel, so all of the following will be possible out-of-the-box:

Split left shift

Split right shift

ANSI/ISO/Big J Enter (nooooo)

Split backspace

Split + on numpad

Split 0 on numpad

Split Enter on numpad

Now, the only other "custom" things I can think of are:

Split space-bar for Code key mod. I've never attempted this one myself, so I'm not sure if any hacking of the barrel plate is necessary to accomplish it? Perhaps an extra stabilizer point or two would help, if they don't interfere with regular layout.

Also, the F62/F77 debate about the split right shift. Watching those threads, a lot of people seemed to want the HHKB style of split right shift, but that would then rule out being able to use a standard long right shift at all.

So, FWIW, my vote is to target a vanilla 89/103 key layout, with support for the Code key space-bar mod, as long as that addition doesn't interfere with a vanilla version.

Yeah, not too crazy I know, but I really feel like IBM finally got the keyboard layout just right when they introduced the Model M.

Split left shift

Split right shift

ANSI/ISO/Big J Enter (nooooo)

Split backspace

Split + on numpad

Split 0 on numpad

Split Enter on numpad

Now, the only other "custom" things I can think of are:

Split space-bar for Code key mod. I've never attempted this one myself, so I'm not sure if any hacking of the barrel plate is necessary to accomplish it? Perhaps an extra stabilizer point or two would help, if they don't interfere with regular layout.

Also, the F62/F77 debate about the split right shift. Watching those threads, a lot of people seemed to want the HHKB style of split right shift, but that would then rule out being able to use a standard long right shift at all.

So, FWIW, my vote is to target a vanilla 89/103 key layout, with support for the Code key space-bar mod, as long as that addition doesn't interfere with a vanilla version.

Yeah, not too crazy I know, but I really feel like IBM finally got the keyboard layout just right when they introduced the Model M.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Just to be clear for me, this is the "Code" key bit?... I actually have one on my desk at the moment. If so, it is just the introduction a new barrel to the right of the spacebar stabilizer blank. It certainly wouldn't get in the way of anything I have setup, but i$ would need to add a capacitive pad for the existing spacebar blank. I would also need to add a cut-out for the spacebar stabilizer barrel two keys to the right of the the left stabilizer barrel in my renderings/pictures (so you would only use 2 of the 3 stabilizer cutouts depending on your layout). I'm certainly up for doing... just curious though, what would you use for the spacebar (assuming I was right about the "Code" key being left side of the split)? I just glanced at my DisplayWrite(r) typewriter, and the spacebar doesn't seem to be any smaller... Or you are thinking future use with new caps?

To rephrase... even though the "Code" key is interesting (I like the idea), I am not sure what you would use as the actual spacebar then for the drop-in unless we have new keys made

EDIT: I have the "Code" key on my desk as inspiration to remind me how I got here... not the DisplayWrite(r) keyboard

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Indeed. My understanding is that split spacebar folks want to use the smaller (Code key) half of the split as a Backspace key, because that's how they roll. Trouble is: where to source smaller spacebars? Were there itty-bitty Japanese spacebar style JIS Model Ms? Does Unicomp supply anything like this?

As for the rest of the board: I'm almost all in favour of following IBM's lead and going straight traditional SSK / fullsize Model M layout, with the addition of 2x 1u keys between each Control and Alt for the extra mods on modern boards. We're just talking capsense pads. No harm in adding these to the PCB, even for those of us planning to use unmodified vintage cases.

Almost? Well, there is one thing. Split right Shift key, HHKB style:

Not exclusively the preserve of HHKBs, far from it:

That key has such a following that Ellipse had to make a separate model of Kishsaver just to satisfy demand! Separate? Because IBM split that looooooong old 2.75u right Shift the other way. On Model Fs and Model Ms alike, there's two barrels and you can either cover the pair with a single 2.75u cap, or with a 1u on the inside/left with a 1.75u cap on the outside/right. I believe IBM did this is to satisfy Japanese and Brazilian layouts, which have an extra key in there, much like ISO crams into the ANSI Return key. Trouble is, that's the *wrong* way for us HHKB fans. And there is no simple solution. Because splitting the 2.75 units the other way around renders the board incompatible with vintage / available right Shifts!

Now, how much do I care about this one detail? Not so much, to be honest. The Fn key is absolutely vital on a 60%, so it matters a lot on a Kishsaver. I really prefer it HHKB style. But we're talking TKLs (and icky fullsize boards) here. We'll have arrow keys and the navigation sixpack intact, so Fn is significantly less important. I say go classic.

As for the rest of the board: I'm almost all in favour of following IBM's lead and going straight traditional SSK / fullsize Model M layout, with the addition of 2x 1u keys between each Control and Alt for the extra mods on modern boards. We're just talking capsense pads. No harm in adding these to the PCB, even for those of us planning to use unmodified vintage cases.

Almost? Well, there is one thing. Split right Shift key, HHKB style:

Not exclusively the preserve of HHKBs, far from it:

That key has such a following that Ellipse had to make a separate model of Kishsaver just to satisfy demand! Separate? Because IBM split that looooooong old 2.75u right Shift the other way. On Model Fs and Model Ms alike, there's two barrels and you can either cover the pair with a single 2.75u cap, or with a 1u on the inside/left with a 1.75u cap on the outside/right. I believe IBM did this is to satisfy Japanese and Brazilian layouts, which have an extra key in there, much like ISO crams into the ANSI Return key. Trouble is, that's the *wrong* way for us HHKB fans. And there is no simple solution. Because splitting the 2.75 units the other way around renders the board incompatible with vintage / available right Shifts!

Now, how much do I care about this one detail? Not so much, to be honest. The Fn key is absolutely vital on a 60%, so it matters a lot on a Kishsaver. I really prefer it HHKB style. But we're talking TKLs (and icky fullsize boards) here. We'll have arrow keys and the navigation sixpack intact, so Fn is significantly less important. I say go classic.

- need

- Location: United Kingdom

- DT Pro Member: -

sorry about the confusion guys...I didn't know the split spacebar "Code" key was actually a thing.

The reason it was asked is solely because I really enjoy having my left thumb for backspace. I've gotten really adapted to it, guess it makes sense to engage with the thumb more.

But now realised keycaps can be a problem...!?

Thank you for even considering it.

The reason it was asked is solely because I really enjoy having my left thumb for backspace. I've gotten really adapted to it, guess it makes sense to engage with the thumb more.

But now realised keycaps can be a problem...!?

Thank you for even considering it.

- Attachments

-

- IMG_1434.JPG (70.45 KiB) Viewed 15060 times

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Knew that was what you guys were up to!

Splitting the huuuuuuuuge spacebar does make sense. Thumbs can handle a lot better use than just that one key. But it's quite a hassle sourcing caps. And at least as troublesome as the HHKB split Shift regarding retaining original keyset compatibility.

Fun math time: IBM's spacebars are 7 units*. Using two right Shifts like your image above, you cover 5.5 units. Add a third key, this time 1.5 units, and you've got all 7. I'd put that key in the middle for symmetry's sake (and because I press Space from the right rather than the centre) that would potentially make a smart layout. However! Shifts and Control keys aren't convex like spacebars. So it'd sure feel odd, as well as invite compatibility trouble in case you want to go back to a real spacebar.

Splitting space is a nice idea, but has a lot of fallout.

*Oh, by the way: screw Unicomp's own boards. We're strictly talking IBM originals, and Unicomp's available caps for them. "Large" Shifts as they call them. Things go right pear shaped if we include Unicomp's own bastardisation of the layout, and next to no one is remotely interested in their modern boards anyway. There'll be a whiner or two, but no buyers!

Splitting the huuuuuuuuge spacebar does make sense. Thumbs can handle a lot better use than just that one key. But it's quite a hassle sourcing caps. And at least as troublesome as the HHKB split Shift regarding retaining original keyset compatibility.

Fun math time: IBM's spacebars are 7 units*. Using two right Shifts like your image above, you cover 5.5 units. Add a third key, this time 1.5 units, and you've got all 7. I'd put that key in the middle for symmetry's sake (and because I press Space from the right rather than the centre) that would potentially make a smart layout. However! Shifts and Control keys aren't convex like spacebars. So it'd sure feel odd, as well as invite compatibility trouble in case you want to go back to a real spacebar.

Splitting space is a nice idea, but has a lot of fallout.

*Oh, by the way: screw Unicomp's own boards. We're strictly talking IBM originals, and Unicomp's available caps for them. "Large" Shifts as they call them. Things go right pear shaped if we include Unicomp's own bastardisation of the layout, and next to no one is remotely interested in their modern boards anyway. There'll be a whiner or two, but no buyers!

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

So to surmise... Do a 103 key, but for giggles... Make every stabilzer stem "capasensed" in case someone dreams up a way to use. This leaves the layout as-is, but let's everything be available "in case". With the addition of the Windows/control key that would be available if someone decided to modify the outer shell to make space for a key between the ctrl and alt.

Correct me off I'm wrong...

We'll worry about the umpteen possibilities when we are making our own cases, and can dictate our keys. Sound good?

Correct me off I'm wrong...

We'll worry about the umpteen possibilities when we are making our own cases, and can dictate our keys. Sound good?

Last edited by lot_lizard on 26 May 2016, 05:36, edited 1 time in total.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Perfect... But if someone disagrees, please object. Even if someone else knows more than you, objections are causing them to think in a way they wouldn't have before your response. There are no bad ideas or comments in this thread (whole idea is outside of the box to begin with).

Part two, the one actually regarding cost... Chew on barrel/flipper/spring cost options and report back when you have digested.

If someone has more pull there with Ellipse, please feel free to use it, and report back. I can tell you confidently that we could do it ourselves for less than $1 USD per key (even using domestic production in US or Europe), but I might have better connections to molds and extrusions than he does. I would prefer to use his barrels and flippers because of the following:

Part two, the one actually regarding cost... Chew on barrel/flipper/spring cost options and report back when you have digested.

If someone has more pull there with Ellipse, please feel free to use it, and report back. I can tell you confidently that we could do it ourselves for less than $1 USD per key (even using domestic production in US or Europe), but I might have better connections to molds and extrusions than he does. I would prefer to use his barrels and flippers because of the following:

- we know they work (or if they don't, and we all die together)

- parts are interchangeable between our projects

- they are 4704 style barrels, and no human is sacrificing a 4704 for a FSSK/FEXT (at least I wouldn't). Bigfoot and XT are saved!

- elecplus

- Location: Kerrville, TX, USA

- DT Pro Member: 0082

- Contact:

Dumb question time here...if you split the spacebar into pieces, and delegate the right half as space and the left half as backspace, what about us lefties who always use the left thumb on the spacebar? Will your keyboard be somewhat programmable, so these can be reversed? To throw another wrench in the works, why do the keys of the far left and right have to be larger anyways? They all used to be the same size, before the AT and XT were introduced. But I have no idea if Shift, Enter, Ctrl, etc come in 1U as standard caps anymore.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Hey guys what about a DT logo? We could have this as an option when/if we make new badges along with the IBM ones.

- pyrelink

- Location: USA

- Main keyboard: HHKB 2

- Main mouse: CST L-Trac

- Favorite switch: Capacitive Buckling Spring

- DT Pro Member: -

Great news! I would agree that keeping things original would be preferred for this go around. The SSK really is great as is, and split right shift is not nearly as important on it as it is on a 60% (as Muirium said). Just a standard F drop in for the SSK is all I want.

On the issue of Flippers/Barrels... Well I am torn. On one hand I (personally) would prefer not to buy barrels from the Ellipse Project for a buck a pop (also constrains us to his timeline). And I would prefer to use standard XT barrels as I have a large stockpile of them already (sourced from grass fed, free range, sustainably farmed BigFoots of course!) however that leaves me biased. And as the conductor of the drop in F assembly train, I certainly respect your wishes on wanting to sustain the population of XT/Bigfoots. I imagine there are some of us here who already have barrels and flippers that they can use, however there are probably also quite a few who would benefit from a new set of them.

No matter what the choice is, I will be content, but my main point is:

Go with Ellipse Barrels:

the barrels are 4704 (AT) Barrels so they have to be sourced from Ellipse or an AT/4704/F122 board (possibly making future replacements/supply lower. High cost per barrel and flipper, and this project is limited by his shipping times.

Go with our own designed barrels:

make them XT barrels, and then they can be sourced from XTs and Bigfeet, thus decreasing population, however maintaining future replacements and components. Hopefully cheaper than Ellipse's barrels. Pyrelink doesn't have to buy any (though he probably will anyway).

Also Cindy: These boards use xwhatsit's Model F controller, so they are fully programmable so if we were to do a split spacebar (which I personally would not want for this project) you could assign either side to either function.

On the issue of Flippers/Barrels... Well I am torn. On one hand I (personally) would prefer not to buy barrels from the Ellipse Project for a buck a pop (also constrains us to his timeline). And I would prefer to use standard XT barrels as I have a large stockpile of them already (sourced from grass fed, free range, sustainably farmed BigFoots of course!) however that leaves me biased. And as the conductor of the drop in F assembly train, I certainly respect your wishes on wanting to sustain the population of XT/Bigfoots. I imagine there are some of us here who already have barrels and flippers that they can use, however there are probably also quite a few who would benefit from a new set of them.

No matter what the choice is, I will be content, but my main point is:

Go with Ellipse Barrels:

the barrels are 4704 (AT) Barrels so they have to be sourced from Ellipse or an AT/4704/F122 board (possibly making future replacements/supply lower. High cost per barrel and flipper, and this project is limited by his shipping times.

Go with our own designed barrels:

make them XT barrels, and then they can be sourced from XTs and Bigfeet, thus decreasing population, however maintaining future replacements and components. Hopefully cheaper than Ellipse's barrels. Pyrelink doesn't have to buy any (though he probably will anyway).

Also Cindy: These boards use xwhatsit's Model F controller, so they are fully programmable so if we were to do a split spacebar (which I personally would not want for this project) you could assign either side to either function.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Excellent point, and should have been mentioned in the original list of tradeoffs. I got the impression from him via PM that he was quite a few extras made on the his "early bird" run (currently shipping in July I believe), but I'm not sure there would be even enough to cover what we would need, and might have to wait until closer to the end of the year. I would conform that if the expense seemed acceptable to everyone.

It is a tough choice. Ultimately, we might actually want to even create some poll to get the vote of those interested but less willing to throw their opinion out?