Not in my price range but it's definitely not original work.

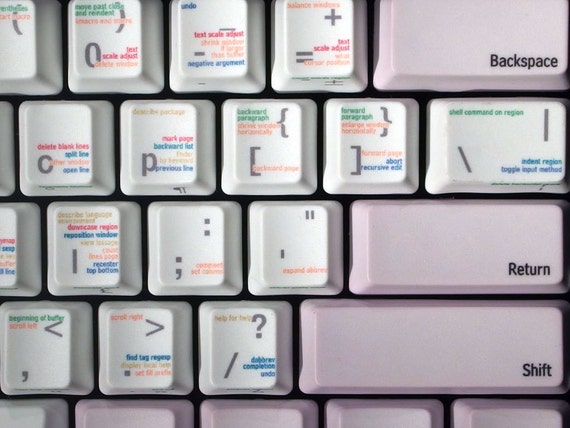

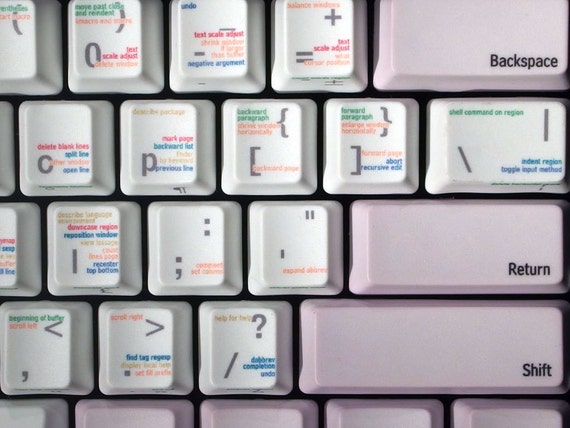

I believe that the sublimation is a single operation, using special CMYK inks in an inkjet printer deposited onto a transfer foil, which is then pressed upon the keycap using a vacuum pump and with heat applied. If anyone knows where to look, I'd be grateful for a reminder where to find the blog of Nakazoto-san, it's very informative.

Yeah, I feel like this would really be great for utility if needed, not necessarily for aesthetics. I do actually have a few of his BS caps though and they are quite nice and fun for a decent price (like $5 or something).

I did consider it, and a few practical considerations gave me pause:

I meant proper injection molding. Since it is an M where the rows are curved via means of the backplate and not via differing keycap shapes, you only really need to design a single keycap shape (if you are okay with sphericals just for the 1u keys). Plus, as you say, you already have the tight tolerance stem part in place. So it is a much less involving endeavour than having to design viable keycaps for an entire flat plate keyboard.

For the cap shape, you could look around in threads here for people who designed various keycap shapes with the goal of injection molding, there are a few spherical keycap design/redesign manufacture/remanufacture initiatives around as far as I can recall. Maybe you can cooperate with those people, or at least ask for their input.tigpha wrote: but I'd have to be a very skillful sculptor to make the appropriate outside form. Either that or obtain the outside shape from a different make and model of key cap. I have an old HP terminal keyboard that could serve the purpose, it's the only one I have with spherical caps.

Yes, not really knowing the dye sublimation process I indeed did not consider this. Maybe you could ask Nakazato-san what the possibilities are there? Maybe he sees a challenge (or value) in working out a good transfer process for spherical caps, and then we created something new and useful for the world. We will never know if we don't ask.

Update: He said PBT sphericals for M is a great idea, and if we can give him PBT spherical keycaps (not ABS), then he can print them.

Code: Select all

//measures are in millimeters

AY=18.5;

AX=19.0;

BY=12.5;

BLX=14.5;

EZ=11.0;

FLZ=14.0;

H=12.75;

CYL_OFF_Z=50;

CYL_DEPTH=0.1;

CLIP_X=2;

CLIP_Y=0.75;

CLIP_H=3*CLIP_Y;

CORNER_RADIUS=2;

WallThickness=0.75;

ClipWidth=2.2;

ClipDepth=0.75;

//ascfront=FLZ/sqrt(pow(FLZ,2)-pow(H,2));

//asctop=(H-EZ)/sqrt(pow(BLX,2)-pow((H-EZ),2));

alpha=asin((H-EZ)/BLX);

beta=asin(H/FLZ);

gamma=90-asin((0.5*(AY-BY))/EZ);

module keycap(){

scale([AX/(AX+2*CORNER_RADIUS),AY/(AY+2*CORNER_RADIUS),1])

translate([CORNER_RADIUS,CORNER_RADIUS,0.01])

minkowski(){

difference(){

cube([AX,AY,H]);

rotate(a=gamma,v=[1,0,0]) cube([100,100,100]);

translate([0,AY,0]) rotate(a=90-gamma,v=[1,0,0]) cube([100,100,100]);

translate([0,0,EZ]) rotate(a=-alpha,v=[0,1,0]) translate([-50,0,0]) cube([100,100,100]);

translate([0,AY/2,EZ+CYL_OFF_Z]) rotate(a=90-alpha,v=[0,1,0]) cylinder(h=100,center=true,r=CYL_OFF_Z+CYL_DEPTH,$fa=1);

translate([AX,0,0]) rotate(a=beta-90,v=[0,1,0]) cube([100,100,100]);

}

cylinder(h=0.01,r=CORNER_RADIUS,$fs=0.6);

//rotate(a=90,v=[1,0,0]) cylinder(h=0.01,r=1,$fs=0.3);

}

}

module clip(){

difference(){

cube([CLIP_X,CLIP_Y,CLIP_H]);

translate([0,CLIP_Y,0]) rotate(a=asin(CLIP_Y/CLIP_H),v=[1,0,0]) cube([100,100,100]);

}

}

i=1;

j=1;

translate([i*(AX+WallThickness),j*(AY+WallThickness),0]){

translate([(AX-CLIP_X)/2,WallThickness,0]) clip();

translate([0,AY,0]) mirror([0,1,0]) translate([(AX-CLIP_X)/2,WallThickness,0]) clip();

difference(){

keycap();

translate([WallThickness, WallThickness, 0]) scale(v=[1-2*WallThickness/AX, 1-2*WallThickness/AY, 1-WallThickness/H]) keycap();

}

}Even at £3,000 if 100 people buy, it will only be £30 per person. But I think you can find considerably cheaper. US-China ICOMold for example starts at $995 USD. And I've heard even lower than that.tigpha wrote: This guide mentions costs starting from at least £3,000 up to £20,000.