Ok, let's set up the group buy...

Model MF - GB CLOSED

- E TwentyNine

- Main keyboard: AT Model F w/ Tenkeyless mod

- Main mouse: Logitech M310

- Favorite switch: Beam spring

- DT Pro Member: -

- Contact:

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

I don't mind profiting. That second part does worry me though!

But for that partnership to really happen someone from community have to work there, otherwise phone will be too broken to work. I'm actually greatly surprized there's no official unicomp presence on DT - I admit they can't seriously consider this forum from any commercial perspective, but basic interest in keyboards should've driven them here, and if no one at Unicomp takes interest in keyboards.. well.. they deserve to be shut down, despite being the source of the buckling spring keys. (Though maybe there's someone from Unicomp there, keeping incognito in fear of the incoming wave of rotten tomatoes

- Phenix

- -p

- Location: Germany, Cologne

- Main keyboard: F122, soarer´d|Novatouch-s

- Main mouse: Roccat Kone Pure|Rollermouse

- Favorite switch: BS F|Topre-s

- DT Pro Member: -

This sounds really interesting, cant wait to see pics!lot_lizard wrote:haha... I smell a MASS Unicomp employee exodus in the near future. I agree they are dying. The idea with any partnership would be to give them our designs and let them morph into their own little animal while we journey on. We have a lot of good ideas in the works for improved beamspring switch designs (shorter profile), etc, and it would let our little hobby work here have an afterlife. We prove the concepts with our GBs, and let them worry about mass producing. There is a market for the MF (small, but there) going forward, but the fun in all of this is coming up with it in the first place (as you say !!SCIENCE!!). Let someone else try to profit from it if they can manage to. It keeps them "viable", or at least appear to the outside world like they are still trying. Maybe then we could influence the dye-subbing a bit. I think the cap and cap mold quality itself is acceptable, it's just the fonts and placement that are horrid (along with picking bad color matches).

SIDE NOTE: I have been on the phone with our metal fab friends almost daily this week to really finalize future visions. They have agreed to be our mold producer for barrels, flippers, Cherry adapters, whatever going forward. I have their mold templates (Solidworks), and will start taking a first pass at the mold creation. They will fine tune my models and mill them out for us. This will save MASSIVE amounts going forward (think 1/2). Pretty amped about it. I think we have realistic chances of knocking this stuff out

__red__ wrote:I guess now is as good a time as any to mention that I'm building an ergonomic split beamspring keyboard...

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Love... and look forward to seeing. Glad you mentioned. Our conversations have been focused around targeting the switch itself. Since we are going to need to be making it from scratch (nothing to source in quantity), we will be making new ones. There is an obvious ~50% that we could reduce the profile height that we would like to take advantage of. While at it, maybe come up with a "key stem" adapter that lets it work with multiple switch mounts (including legacy beamer caps). All early on yet in conception, but maybe we marry the projects up at some point?

- E TwentyNine

- Main keyboard: AT Model F w/ Tenkeyless mod

- Main mouse: Logitech M310

- Favorite switch: Beam spring

- DT Pro Member: -

- Contact:

Yeaaaah....there definitely needs to be a thread on this.lot_lizard wrote:Love... and look forward to seeing. Glad you mentioned. Our conversations have been focused around targeting the switch itself. Since we are going to need to be making it from scratch (nothing to source in quantity), we will be making new ones. There is an obvious ~50% that we could reduce the profile height that we would like to take advantage of. While at it, maybe come up with a "key stem" adapter that lets it work with multiple switch mounts (including legacy beamer caps). All early on yet in conception, but maybe we marry the projects up at some point?

/lumberg

- seebart

- Offtopicthority Instigator

- Location: Germany

- Main keyboard: Rotation

- Main mouse: Steelseries Sensei

- Favorite switch: IBM capacitive buckling spring

- DT Pro Member: 0061

- Contact:

No, not good enough for me; DMA and lot_lizard need to take over Unicomp and start a whole new Unicomp SSK project. We have various files on hand (not sure what the copyright situation is there) and then when that's rolling the next level is a Beamspring reincarnation of sorts (don't ask me how that's going to work)...

keyboards-f2/a-proposal-for-a-new-ssk-t ... comp%20ssk

Need any more...

Spoiler:

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

The "this Asian kid" disclaimer made me actually laugh out loud (no emoji required). We'll do what we can... I think we are really on the cusp of something intriguing over this next year.

Now that the MF phase 1 is proving itself (you guys will like), it makes me realize that there is SO much potential in all of this. I want the beamspring switch though. That is the holiest of holies. There are things I would change about it though (throw length, caps are gorgeous but a little too spherical for rapid work, etc). I realize my views are in the minority about the caps, but I own 9 unique beamsprings and use all but the 3277 often (half of daily driving writing code in Java/PHP/Ruby/C++ all day). The caps are my biggest hangup. Beamspring caps are TOO sexy to actually work from, and the actuation length is 1/3 too long.

The M and F caps are a bit bland but the switch is delicious if light and crisp. SP's SA caps are too bland as well, though I appreciate the double shot. Something in the middle of SA and Beamspring is heavenly. I hope that is Matt3o's mission with his new sphericals (I should follow his thread more closely... it's fantastic). Something that is a typist's cap. Cup my finger perfectly while ignoring row composition. Lets have 25 unique molds if we need it (not just 5-7 rows).

I think we get WAY too caught up in row composition and appearance. I LOVE my keyboard to look amazing, but I would MUCH prefer to type on a Stradivarius if it existed. $1k+ per board if it was the end all... wouldn't blink. To me, the ULTIMATE prize is to marry the M layout, F switch actuation, Beamspring feel AT actuation, the Topre throw length, on a common Cherry MX mount, with some key profile that is yet to exist in quintuple shots (between SA and Beamer profile). All in a case that doesn't need some smurfy weight plate because is it made properly to begin with (aluminum won't do). Then I am finally happy.

Now that the MF phase 1 is proving itself (you guys will like), it makes me realize that there is SO much potential in all of this. I want the beamspring switch though. That is the holiest of holies. There are things I would change about it though (throw length, caps are gorgeous but a little too spherical for rapid work, etc). I realize my views are in the minority about the caps, but I own 9 unique beamsprings and use all but the 3277 often (half of daily driving writing code in Java/PHP/Ruby/C++ all day). The caps are my biggest hangup. Beamspring caps are TOO sexy to actually work from, and the actuation length is 1/3 too long.

The M and F caps are a bit bland but the switch is delicious if light and crisp. SP's SA caps are too bland as well, though I appreciate the double shot. Something in the middle of SA and Beamspring is heavenly. I hope that is Matt3o's mission with his new sphericals (I should follow his thread more closely... it's fantastic). Something that is a typist's cap. Cup my finger perfectly while ignoring row composition. Lets have 25 unique molds if we need it (not just 5-7 rows).

I think we get WAY too caught up in row composition and appearance. I LOVE my keyboard to look amazing, but I would MUCH prefer to type on a Stradivarius if it existed. $1k+ per board if it was the end all... wouldn't blink. To me, the ULTIMATE prize is to marry the M layout, F switch actuation, Beamspring feel AT actuation, the Topre throw length, on a common Cherry MX mount, with some key profile that is yet to exist in quintuple shots (between SA and Beamer profile). All in a case that doesn't need some smurfy weight plate because is it made properly to begin with (aluminum won't do). Then I am finally happy.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

That requires unboxing and the wife getting "wifey". "Why are all these @#$%@#$%@#$%@#$%ing things spread out!!!!"

Some day

-

__red__

- Location: Beamspringville

- Main keyboard: 4704

- DT Pro Member: 0186

Blame DMA with his fine work on the new F(at) controller (Yes, that was a Tomos yr Tanc reference).

I have ~55 beamswitch keys so I don't have enough to make my usual "Battleship"-style layout. Figured I'd toy with the idea of building an ~60% and, just because - why not try and make it ergonomic?

I've never used an ergo keyboard and as a non-touch typist I'm a little scared. If I can build an ergo where the pieces will fit together as well (may not be practical) then that would be doubly ideal.

Rumours of me having an RFQ out with chemical milling fabricators to do fabrication of the spring parts of mechanism are of course widely exaggerated.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

Ergonomic is almost an oxymoron, if it's going to have the same crazy tall case as the original beamspring!__red__ wrote:I guess now is as good a time as any to mention that I'm building an ergonomic split beamspring keyboard...

Edit: I hadn't read the chatter about cutting 50% off the height. That would make it a lot more reasonable.

Last edited by Techno Trousers on 10 Feb 2017, 04:38, edited 1 time in total.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

Shoot, I've been working all day and missed this gem. That's fantastic news, lizard. I know how much you like working with your friends, and I'm sure they will do a great job on the molds.lot_lizard wrote: SIDE NOTE: I have been on the phone with our metal fab friends almost daily this week to really finalize future visions. They have agreed to be our mold producer for barrels, flippers, Cherry adapters, whatever going forward. I have their mold templates (Solidworks), and will start taking a first pass at the mold creation. They will fine tune my models and mill them out for us. This will save MASSIVE amounts going forward (think 1/2). Pretty amped about it. I think we have realistic chances of knocking this stuff out

-

andrewjoy

- Location: UK

- Main keyboard: Filco ZERO green alps, Model F 122 Terminal

- Main mouse: Ducky Secret / Roller Mouse Pro 1

- Favorite switch: MX Mount Topre / Model F Buckling

- DT Pro Member: 0167

SolutionTechno Trousers wrote:Ergonomic is almost an oxymoron, if it's going to have the same crazy tall case as the original beamspring!__red__ wrote:I guess now is as good a time as any to mention that I'm building an ergonomic split beamspring keyboard...

Edit: I hadn't read the chatter about cutting 50% off the height. That would make it a lot more reasonable.

Cut a hole in your desk and recess the beamspring.

- seebart

- Offtopicthority Instigator

- Location: Germany

- Main keyboard: Rotation

- Main mouse: Steelseries Sensei

- Favorite switch: IBM capacitive buckling spring

- DT Pro Member: 0061

- Contact:

Yeah the "Asian kid" is obviously just for fun but those SSK renderings were made by a former DT member who seriously got into the idea of planning a modern SSK. I don't recall the whole story now but I believe he even approached Unicomp at some point, of course we now know Unicomp does not actually want to produce anything new. Oh well.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Nothing in any official capacity, but some of us have been tinkering with it in the shadows. My focus was going to be to replicate the switch in a minimal form factor. Others had kicked around some thoughts on different layouts, etc. The plates will actually be quite inexpensive to produce by comparison to everything we are doing here. It's the switch, PCB, controllers that are the buggers. All yik-yak so far I believe unless someone has unannounced progress. I have some switch designs mocked up, but that is going to be a long road of testing many prototypes... so nothing to get excited about yet.

- E TwentyNine

- Main keyboard: AT Model F w/ Tenkeyless mod

- Main mouse: Logitech M310

- Favorite switch: Beam spring

- DT Pro Member: -

- Contact:

Beam plates would be cheaper? They're at least twice as thick as cap plates. Why cheaper?

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

They're flat plates, right? I haven't owned a beamspring myself. Just too expensive each time I've seen one.E TwentyNine wrote:Beam plates would be cheaper? They're at least twice as thick as cap plates. Why cheaper?

I think it's a big labor cost to roll the MF plates.

- E TwentyNine

- Main keyboard: AT Model F w/ Tenkeyless mod

- Main mouse: Logitech M310

- Favorite switch: Beam spring

- DT Pro Member: -

- Contact:

Yeah they're flat and the holes are simple. Guess that would explain it.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Exactly.. the tension really isn't very important because the switch is more self-contained since it's the pad going up into the switch vs. down onto the PCB to initiate a press. Several reasons really. The switches are more complex though (no doubt).

For the MF, the curved plates, tighter holes, all the tapping and countersinking, and offsets bends are what got us. For the beamers, they will be half the machining effort (or less), with a wider tolerance in general.

-

__red__

- Location: Beamspringville

- Main keyboard: 4704

- DT Pro Member: 0186

That had not occurred to me. Knowing that that element is less critical may result in being able to build some of this with off-the-shelf components.

I'm off for some beers with a paper and pencil...

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

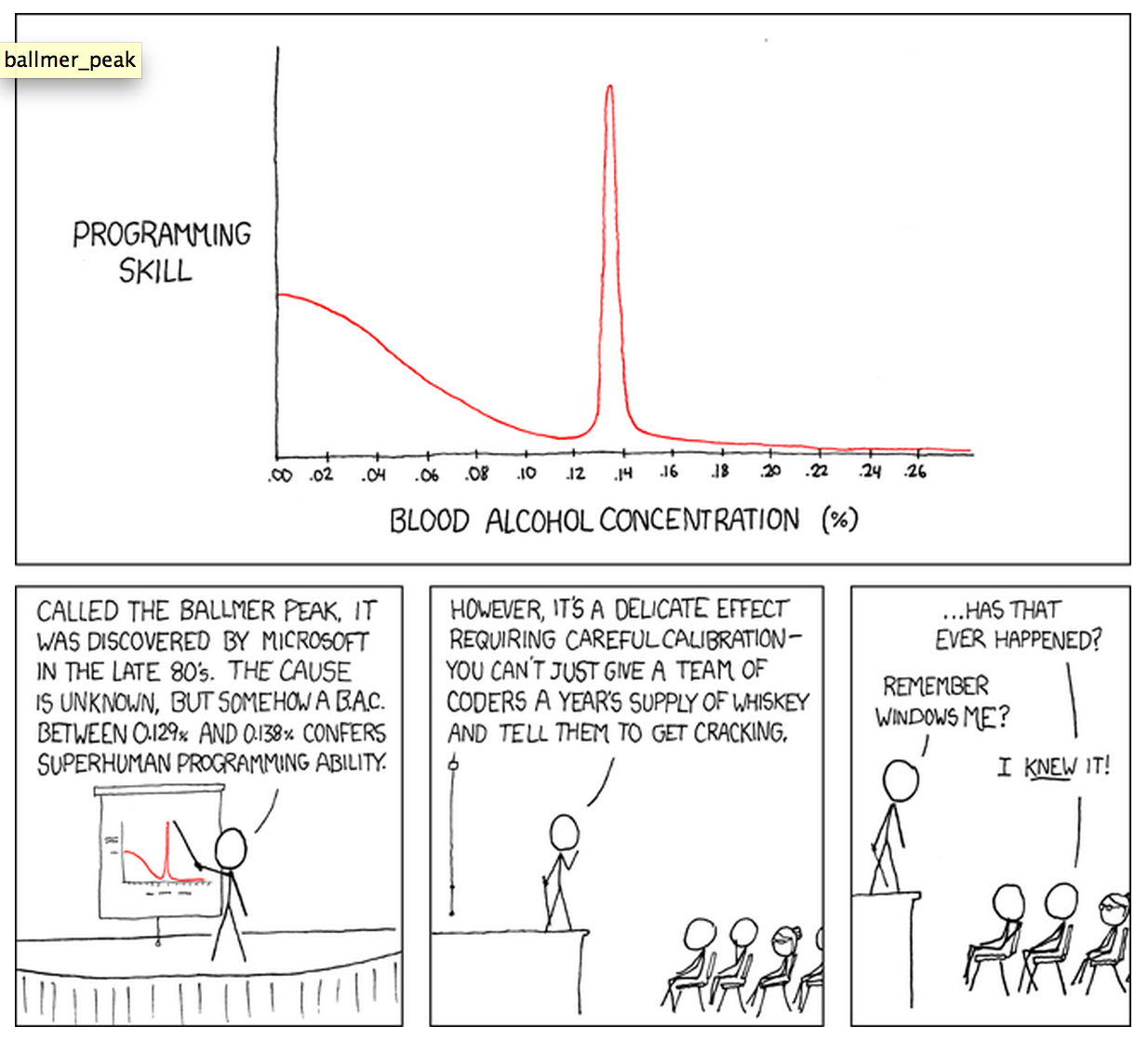

So, since it is 5:00 pm on Friday afternoon, an oldie but a goodie:

https://www.youtube.com/watch?v=-6FnE6y9JIM

https://www.youtube.com/watch?v=-6FnE6y9JIM

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

True... Progress has certainly been made. I shouldn't Kardashian too much. Moral to red was... Dive in. "Beamspring proper" has several bits yet to be revealed. Don't worry because anything considered is still early in planning

-

__red__

- Location: Beamspringville

- Main keyboard: 4704

- DT Pro Member: 0186

Well, I got my first quotes back from fabricators for the metal parts and they were high enough to make that plus PCB design cost-prohibative. If you're saying that the switch is in-hand then I'll focus back on the pcb and controller.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Loads of parts have been delivered, and I am essentially done with all the 3d printed plastic parts. I reached out to our metal fabricator friends, and they are going to move the prototype plate production up as a higher priority. Once it is confirmed, we'll order the PCBs and controllers as well (along with the plates). We were likely targeting the end of February when we kicked this off to start shipments. It is looking more like the middle of March given my work schedule is going to throw a one week delay in here coming up.

The foam to separate the plates, and the packaging (boxes) are currently in production. Again, in the end, we had two total dies made (stabilizer ring foam and the boxes). We own these dies outright, and will reuse in the future for other endeavors. I will ask to get some pictures of the dies so we have something to show. Also, when I do return home... I'll start getting some pics of all these parts out there to see. At this point, I've really just cut boxes to validate the part itself and packing list quantities.

The foam to separate the plates, and the packaging (boxes) are currently in production. Again, in the end, we had two total dies made (stabilizer ring foam and the boxes). We own these dies outright, and will reuse in the future for other endeavors. I will ask to get some pictures of the dies so we have something to show. Also, when I do return home... I'll start getting some pics of all these parts out there to see. At this point, I've really just cut boxes to validate the part itself and packing list quantities.

- ekeppel

- Location: Maine, USA

- Main keyboard: IBM 5251 Frankenbeam XT w/ Modified Layout

- Favorite switch: Beamspring > Capacitive BS > Alps SKCM Brown > U4T

- DT Pro Member: -

Wow, this is moving so much faster than I could have ever anticipated. Thanks for all your hard work in coordinating and executing this!