new big skcm blue alps

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

I have seen some attempts at making new skcm blue alps switches. I wish for more attempts. With the recent lubricant discussion I wondered how we could make a new skcm blue alps switch. Not switches... just 1 switch.

I ordered a Novelkeys big pale blue switch recently which is fun! How can I reuse this return spring? The switch is so big. Would be fun if someone... made a giant skcm blue... Oh yes. You may have learned this about me, but I am full on nutty. Let's go!

So I am going to make a SINGLE new SKCM Blue switch.

I will put all of the detailed cad files here. If people have their own, I would welcome them though. Plz share. Id rather not make them but I will if required.

Most current files here

https://drive.google.com/drive/folders/ ... O0ZjUWYiHZ

So first step right now. Is the click leaf. So, let's begin.

The original click leaf is

0.06mm thick-made steel. (type not necessary) For my recreation I will use 0.178mm steel. Because it's easy to cut and I have a bunch.

So for now. I have made a clickleaf, without the hammered indent on the back. When I model the SKCM shell, I will put it in.

I will have to 3d-print an oblong shape to hammer into the back. That will follow. So for now I have a skcm blue 4x size clickleaf mark 1

I am fully aware my click leaf kind of sucks, but It will get better.

Robb

I have seen some attempts at making new skcm blue alps switches. I wish for more attempts. With the recent lubricant discussion I wondered how we could make a new skcm blue alps switch. Not switches... just 1 switch.

I ordered a Novelkeys big pale blue switch recently which is fun! How can I reuse this return spring? The switch is so big. Would be fun if someone... made a giant skcm blue... Oh yes. You may have learned this about me, but I am full on nutty. Let's go!

So I am going to make a SINGLE new SKCM Blue switch.

I will put all of the detailed cad files here. If people have their own, I would welcome them though. Plz share. Id rather not make them but I will if required.

Most current files here

https://drive.google.com/drive/folders/ ... O0ZjUWYiHZ

So first step right now. Is the click leaf. So, let's begin.

The original click leaf is

0.06mm thick-made steel. (type not necessary) For my recreation I will use 0.178mm steel. Because it's easy to cut and I have a bunch.

So for now. I have made a clickleaf, without the hammered indent on the back. When I model the SKCM shell, I will put it in.

I will have to 3d-print an oblong shape to hammer into the back. That will follow. So for now I have a skcm blue 4x size clickleaf mark 1

I am fully aware my click leaf kind of sucks, but It will get better.

Robb

Last edited by SneakyRobb on 23 May 2020, 17:21, edited 1 time in total.

- //gainsborough

- ALPSの日常

- Location: United States

- Main keyboard: some kind of alps keyboard

- Favorite switch: clk: SKCM blue, lin: SKCL cream, tac: SKCM cream

- DT Pro Member: 0188

Bahahaha. Oustanding. Can't wait to see how this turns out!

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Thanks!//gainsborough wrote: 11 May 2020, 03:11 Bahahaha. Oustanding. Can't wait to see how this turns out!

Hi,

One idea at a time! Too many projects I have...!!

So Update:

I was unable to find any available skcm blue alps 3d models. I asked around and ai03 had a solid exterior model for rendering purposes. Starting with that as a base, the spec sheets and my own calipers I made these 2 models. Also looking at Snack's photos

They are not "proper" 3d models, but they will work as far as I can tell. Still need to test them.

A major reason I am doing this is I have seen several people ask about making new blue alps switches several times before. I want to make a single switch and show how it is done and document every thing about it, so that someone can actually have the CAD, dimensions methods etc etc to make them in the future.

I heavily suggest if you use these models for any actual purposes to basically redo them and to not take any dimensions from them. They are not 100% accurate. Several things are not correct, most notably the 4 triangle tabs and the pegs for the switchplate are missing.

When my orihalcon switches arrive I will likely saw 1-2 in half to get some final inside measurements as well as take apart the switch plates of course.

The giant switch 4x scale will make it much easier for me to 3d print specifically switch plates. Hopefully I will have this printed soon and my pale blue big switch from novelkeys arrives so I can take the return spring out.

I will also upload a DXF of the click leaf soon. I am trying to calculate the material lost due to bending and figuring out the best way to stamp the indent on it.

The first few models will probably be clear/white. If I am feeling fancy i'll order some black and pale blue 3d printing filament just to get the look perfect.

Until then, enjoy these dubious quality skcm blue alps housing models.

https://grabcad.com/library/skcm-blue-r ... ng-model-1

Glorious images

Last edited by SneakyRobb on 12 May 2020, 23:58, edited 1 time in total.

- ddrfraser1

- Location: United States

- Main keyboard: Changes weekly

- Main mouse: MX MASTER

- Favorite switch: Lubed 55g BKE Redux Domes

- Contact:

Complete mentalist. I fully endorse it.

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi thanks!

I will need to do some adjustments but the 3d prints seem overall okay. Major problem is the slider somehow came out slightly too wide.

The clickleaf based just on measurements fits well though.

I am still waiting on the big switch with the spring and the loose skcm blue alps to cut up for more measurements.

Photos of first prototype 3d prints. Some supports removed.

Will have to revise the shapes and test to see how they work. I might have to adjust the clips that hold the switch together. I am not confident they will be durable enough to clip together, or to be taken apart without cracking.

Zip ties may be needed.

Will update when revisions when I have some!

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

1 more shot just to show the size.

- ddrfraser1

- Location: United States

- Main keyboard: Changes weekly

- Main mouse: MX MASTER

- Favorite switch: Lubed 55g BKE Redux Domes

- Contact:

- abrahamstechnology

- Location: United States

- Main keyboard: Laser with SMK Cherry mount

- Main mouse: Mitsumi ECM-S3902

- Favorite switch: Alps and Alps clones

- DT Pro Member: 0212

Nice!

This may be helpful for my Blue ALPS recreation project

This may be helpful for my Blue ALPS recreation project

- E3E

- Location: United States

- Main keyboard: Blue, Neon Green, Striped Amber, Cream Alps, Topre

- Main mouse: Logitech, Topre

- Favorite switch: Alps, Topre

- DT Pro Member: -

Good stuff, Robb. Very creative! Seeing those recreations of the housing and slider setup is wild. Very nice work thus far.

The wonders of 3D printing. Otherwise, you'd have to do some serious scratch building to get everything precise one even just one side.

The wonders of 3D printing. Otherwise, you'd have to do some serious scratch building to get everything precise one even just one side.

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hey very true and also thanks! The marvels of the modern age. Very sleepy right now so written fast.E3E wrote: 14 May 2020, 04:26 Good stuff, Robb. Very creative! Seeing those recreations of the housing and slider setup is wild. Very nice work thus far.

The wonders of 3D printing. Otherwise, you'd have to do some serious scratch building to get everything precise one even just one side.

Okay. So my printer is at my parents house, but thankfully my brother was able to print the altered slider part.

As mentioned I don't have the return spring yet. Its pretty rough and scratchy as its prototype, but it clicks. It actually clicks. !!!!!!!!!

I will have to use the actual thickness of metal I calculated earlier. I went with a thinner one, but it's actually too thin and barely clicks.

So for the click leaf tomorrow I will upload a work-in-progress DXF.

I did this very quick and dirty, but the SKCM blue alps click leaf has this indent sort of thing on it. I made a really quick and dirty stamp thing to try to make that indent. It's not very well done and was just to see if the 3d print could withstand the clamp pressure...it works.

I'm going to model the stamp thing it so it

1: looks like the indent

2: is accurate. Using rods and the leaf shape I will be able to align the indent.

I have to sleep, but great success!

Images below.

- Polecat

- Location: Downstream from Silicon Valley

- Main keyboard: Monterey K104 Industrial Gray

- Main mouse: Logitech Optical

- Favorite switch: Early Alps SKCM

- DT Pro Member: -

I want one. I havent thought of a use for it, but that's not important right now. I honestly can't think of a better keyboard collectible than this!

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,kralcifer wrote: 14 May 2020, 20:46 I love it SneakyRobb! I'm inspired by your many ideas on other threads as well.

Thanks it really means a lot.

I was morbidly curious so... I had to use clamps and I put it together. I will be making some revisions anyway. I'll probably have to break it apart, but I really just wanted to see it together.

Because of the 3d printing the tolerances between the parts was non existant so I had to really really fight to get it together. It was probably a bad idea, but I was really jonesing to see it together.

I am still working on the click leaf DXF, but I hope to finish it soon. I have taken out the click leaf of a blue alps, white alps and matias click and they feel different but they are so similar its hard to believe that they all feel different. Hard to bend it right.

So. Here it is together!

First is a flashlight on the side so you can see from the top the clickleaf moving inside and how it slaps the housing to make the click noise on the down and up.

As well a sound comparison with an original keyboard. Chicony KB-5161A with blue Alps.

Click leaf moving Sound comparison (obviously original has keycap in case so take into account) Glamour shots

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

Okay never mind. At the lightest attempts the sides fell off! Oop.

For the clickleaf you may notice that it clicks loudly on the upstroke.

There will be significant work in "tuning" the click leaf to perform just right. Alps have a magic of taking almost identical parts and slightly altering them to make them feel totally different.

Thankfully my click leaf is twice as wide as 2 blue alps so its easier to manipulate.

I am still waiting on the return spring from the big switch and my loose switches. They have been stuck in purgatory and I hope they leave the USA and enter Canada soon.

Okay never mind. At the lightest attempts the sides fell off! Oop.

For the clickleaf you may notice that it clicks loudly on the upstroke.

There will be significant work in "tuning" the click leaf to perform just right. Alps have a magic of taking almost identical parts and slightly altering them to make them feel totally different.

Thankfully my click leaf is twice as wide as 2 blue alps so its easier to manipulate.

I am still waiting on the return spring from the big switch and my loose switches. They have been stuck in purgatory and I hope they leave the USA and enter Canada soon.

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

So I don't know how to upload the DXF but the shape is pretty simple. I'll put the click leaf measurements below but they are just images. They are for the real sized click leaf, not the 4x so they need to be multiplied obviously.

Also boom. Yes. Excellent!

Also I am almost done the click leaf indent making device! It has actually turned out super well!

I'll put the measurements at the bottom but here is the progress on the clickleaf indent thing. I'll upload the shape soon as I make some adjustments.

I forgot that the ears on the bottom of the leaf needed space. I am using "Generation 1" click leafs as thats just what I'm doing. If I recall they are less tactile than later ones.

I also used a hole punch for the bottom of one attempt as it was easier to cut it. IMAGES.

This is the original from DT wiki.

And my new attempt. I am super happy with how this indent turned out.

These measurements are constantly changing, but they are roughly accurate. I need to figure out how to get more precise.

So I don't know how to upload the DXF but the shape is pretty simple. I'll put the click leaf measurements below but they are just images. They are for the real sized click leaf, not the 4x so they need to be multiplied obviously.

Also boom. Yes. Excellent!

Also I am almost done the click leaf indent making device! It has actually turned out super well!

I'll put the measurements at the bottom but here is the progress on the clickleaf indent thing. I'll upload the shape soon as I make some adjustments.

I forgot that the ears on the bottom of the leaf needed space. I am using "Generation 1" click leafs as thats just what I'm doing. If I recall they are less tactile than later ones.

I also used a hole punch for the bottom of one attempt as it was easier to cut it. IMAGES.

This is the original from DT wiki.

And my new attempt. I am super happy with how this indent turned out.

These measurements are constantly changing, but they are roughly accurate. I need to figure out how to get more precise.

- Attachments

-

- skcm blue alps click leaf very very rough.JPG (62.98 KiB) Viewed 12727 times

-

- skcm blue alps click leaf 4.JPG (663.84 KiB) Viewed 12727 times

-

- skcm blue alps 5.JPG (830.51 KiB) Viewed 12727 times

-

- skcm blue alps 4.JPG (590.3 KiB) Viewed 12727 times

-

- skcm blue alps 2.JPG (37.44 KiB) Viewed 12727 times

-

- skcm blue 6.JPG (55.02 KiB) Viewed 12727 times

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

So I had a new top housing printed with a window in it to view the click leaf. Very cool. I will cut one of these in the loose switches when they arrive.

Basically you can see why my switch has the click on the upstroke. Due to the slightly poor bending the click leaf is not even. The further away from camera side lifts up and smacks down.

This is just due to myself printing quick and dirty rough models and cutting quickly.

user kralcifer has recommended an SLA printer for resolution which I think I will order soon. My printer is good at macrosized things, but not fine resolutions.

Regardless you can see how the slider pulls the click leaf towards itself, then smacks back and hits the exterior housing. Causing the click!

The refinement of the click leaf will be key, especially when the spring and loose switches come. Then I will have to precisely place the click in line with the switch activation.

So I had a new top housing printed with a window in it to view the click leaf. Very cool. I will cut one of these in the loose switches when they arrive.

Basically you can see why my switch has the click on the upstroke. Due to the slightly poor bending the click leaf is not even. The further away from camera side lifts up and smacks down.

This is just due to myself printing quick and dirty rough models and cutting quickly.

user kralcifer has recommended an SLA printer for resolution which I think I will order soon. My printer is good at macrosized things, but not fine resolutions.

Regardless you can see how the slider pulls the click leaf towards itself, then smacks back and hits the exterior housing. Causing the click!

The refinement of the click leaf will be key, especially when the spring and loose switches come. Then I will have to precisely place the click in line with the switch activation.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Hey, you’re already as smooth as MX reds were circa 2013 when I first got a handful from 7bit and wondered if he was pranking me. And the only way is up! (Back up, without pulling the slider!)

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi, hah!Muirium wrote: 17 May 2020, 21:26 Hey, you’re already as smooth as MX reds were circa 2013 when I first got a handful from 7bit and wondered if he was pranking me. And the only way is up! (Back up, without pulling the slider!)

Yes eventually I will get the novelkeys bigswitch return spring and it will go up on it's own. Then I can really start to know how it will work properly.

Cutting clickleaf by hand introduces a lot of errors. I think it will be easiest to print out a paper shape and tape it to the metal then cut that directly rather than plotting out the shape manually.

I am now cutting a clickleaf that is roughy 0.25mm thick. The loudness of the switch will be...extreme.

If I was really really nutty...I could cut a SKBM contact mechanism. Oh god that would be the height of cursed.

I'm doing it.

I have also decided to make my own "doubleshot" keycap. With the printer I can make it in ABS and acetone smooth it. Then manually pour in the legend.

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

I haven't actually tried MX reds. Only silent Reds one time. They felt like silent mx browns almost. Was curious

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

MX had a really bad period, just when I was first getting into keyboards, which meant serious disappointment on first contact. Scuffy, inconsistent, downright nasty linear action; which is the only thing MX is fundamentally any good at! Colour me not the most impressed when I got my paws on them.

Cherry “retooled” since then and the sliders -slide- a bit better now. Not as bad a mess as the notorious first gen Box switches which killed caps, but if there’s a lesson to learn from the manufacturers: never offer your users a refund, no matter the seriousness of your flaws!

Cherry “retooled” since then and the sliders -slide- a bit better now. Not as bad a mess as the notorious first gen Box switches which killed caps, but if there’s a lesson to learn from the manufacturers: never offer your users a refund, no matter the seriousness of your flaws!

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

Will update later today, but doing some testing right now!!

Will update later today, but doing some testing right now!!

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

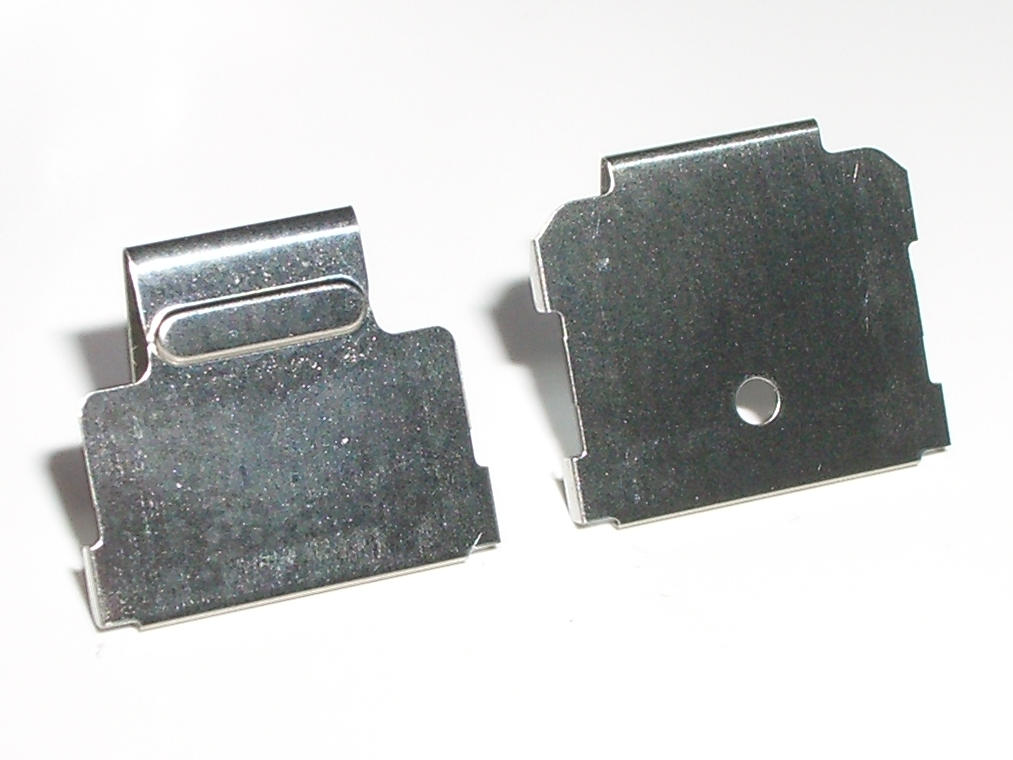

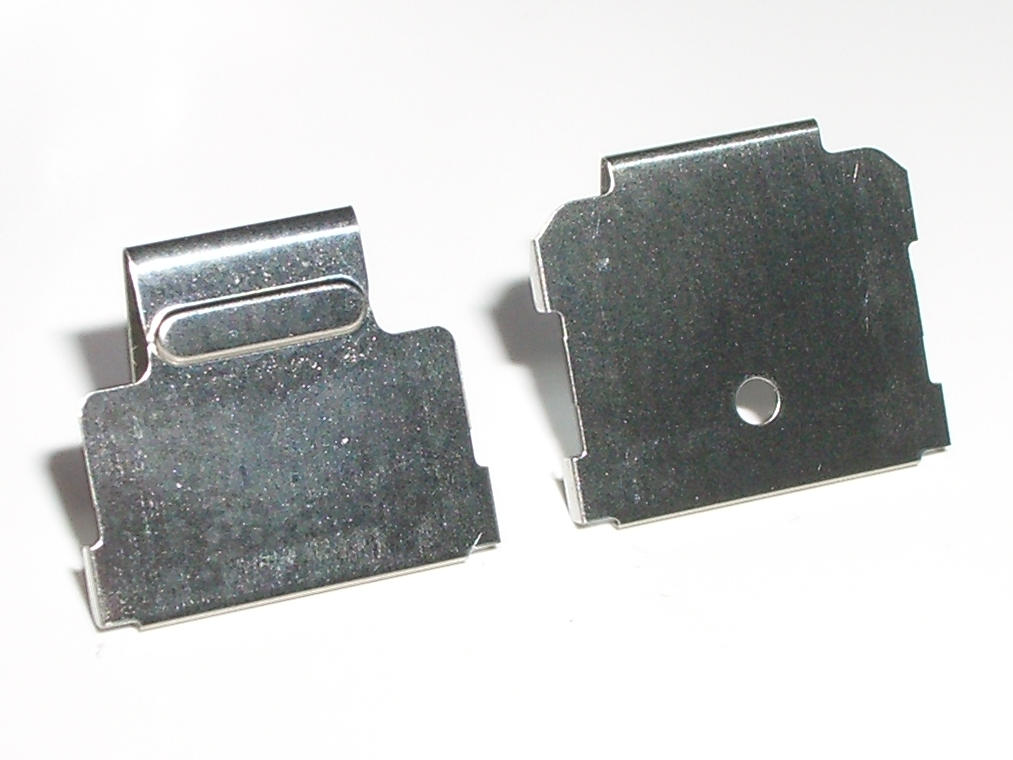

So I've been trying to bend this switch plate metal piece into shape but my hand plier/stools just aren't doing it. I've ordered a vice and some sheet metal pliers to make actual precise bends. As well as a proper square hole punch for nice interior edges. I kind of mangled this one!!!

I may also just get a small hobby metal bending brake, probably the best long term option.

My first attempt at making the switch plate metal part was obviously.. not great. We are getting there though.

Eventually I will use the CNC to make the metal contact pieces. These are just for sizing. I could also cut them from thinner metal and affix them to these plastic frames... options options.

I have been using a slider from grabcad that I did not make, but I will make my own slider soon. Can't find that link...

I'll share some files like the DXFs etc. As a warning these files exist merely for me to work off of, so they are not necessarily usable for you. Or even 100% accurate. They are just what I am working with at the moment. Because my switch is so big, variations are very easy to work around. I have a huge tolerance to work with.

All files are sized for a normal sized skcm blue switch.

https://drive.google.com/open?id=1O4MKu ... O0ZjUWYiHZ

So I've been trying to bend this switch plate metal piece into shape but my hand plier/stools just aren't doing it. I've ordered a vice and some sheet metal pliers to make actual precise bends. As well as a proper square hole punch for nice interior edges. I kind of mangled this one!!!

I may also just get a small hobby metal bending brake, probably the best long term option.

My first attempt at making the switch plate metal part was obviously.. not great. We are getting there though.

Eventually I will use the CNC to make the metal contact pieces. These are just for sizing. I could also cut them from thinner metal and affix them to these plastic frames... options options.

I have been using a slider from grabcad that I did not make, but I will make my own slider soon. Can't find that link...

I'll share some files like the DXFs etc. As a warning these files exist merely for me to work off of, so they are not necessarily usable for you. Or even 100% accurate. They are just what I am working with at the moment. Because my switch is so big, variations are very easy to work around. I have a huge tolerance to work with.

All files are sized for a normal sized skcm blue switch.

https://drive.google.com/open?id=1O4MKu ... O0ZjUWYiHZ

- ddrfraser1

- Location: United States

- Main keyboard: Changes weekly

- Main mouse: MX MASTER

- Favorite switch: Lubed 55g BKE Redux Domes

- Contact:

Noice

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi thanks.

I wanted to know how dimensionally accurate my dxf files were so for fun I have flattened the click leaf and I suppose it's a leaf spring.

I will make adjustments accordingly

I will tomorrow compare these images with my dxf files. I probably should use a scanner though. I'll see about that.

The clickleaf is a so-called 2nd generation one so it is slightly different but no matter.

Regardless behold the carnage.

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

HI,

I did the scan of the flattened metal pieces. I have adjusted the DXF files for them accordingly

Here are the scans, the pdf is in the google drive.

Here is my attempts to overlay and compare. The red ones are the new ones in the comparisons This one you cant see much black because the old black is mostly covered by the red, there was less dimensional errors in this one. And finally here is a bottom shot where I am comparing the lower view of my parts beside the original.

The printer printed the switch plate mirrored, which is why the legs are opposite of the original, but that doesn't matter too much right now.

It does click, and the leafspring when I get a punch to put the divot into it, does press on the switchplate plastic.

So excellent, progress is being made!

I did the scan of the flattened metal pieces. I have adjusted the DXF files for them accordingly

Here are the scans, the pdf is in the google drive.

Here is my attempts to overlay and compare. The red ones are the new ones in the comparisons This one you cant see much black because the old black is mostly covered by the red, there was less dimensional errors in this one. And finally here is a bottom shot where I am comparing the lower view of my parts beside the original.

The printer printed the switch plate mirrored, which is why the legs are opposite of the original, but that doesn't matter too much right now.

It does click, and the leafspring when I get a punch to put the divot into it, does press on the switchplate plastic.

So excellent, progress is being made!

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

So rather hilariously the big switch spring wont work. It's just... too big. You thought this would be too easy didn't you reader?

I could try to make the slider narrower but its already basically the same width. No matter! I have ordered a spring that is roughly accurate at a narrower outside diameter. If that does not work I will simply make the spring.

This weekened I will recut the click leaf and leaf spring to my newer dimensions for further fun. I will 3d print a small press die like above for the bump indent on the leaf spring to actuate the switch plate for contact.

As well I will order a square hole punch for sheet metal for good hole-consistency. This is for the leaf spring that goes on the switch plate to have a good clean internal hole structure.

As well for some reason my keycap printed mirrored!!!!!!!!!!!!!! No matter. I will use it for double shot practice. I will clean the keycap up and then try to pour resin in, to create the double shot effect. I am thinking whether I should paint it then double shot it, or what order to do this in. Not sure. Maybe i'll just get beige filament. Cursed.

I got this small bench vise to help bending metal before I get the full metal bending brake. SO CUTE. And finally here is a family photo with the big switch, the spring of which is too big. Guess My future 4x scale macro pad will also have a big pale blue switch.

So rather hilariously the big switch spring wont work. It's just... too big. You thought this would be too easy didn't you reader?

I could try to make the slider narrower but its already basically the same width. No matter! I have ordered a spring that is roughly accurate at a narrower outside diameter. If that does not work I will simply make the spring.

This weekened I will recut the click leaf and leaf spring to my newer dimensions for further fun. I will 3d print a small press die like above for the bump indent on the leaf spring to actuate the switch plate for contact.

As well I will order a square hole punch for sheet metal for good hole-consistency. This is for the leaf spring that goes on the switch plate to have a good clean internal hole structure.

As well for some reason my keycap printed mirrored!!!!!!!!!!!!!! No matter. I will use it for double shot practice. I will clean the keycap up and then try to pour resin in, to create the double shot effect. I am thinking whether I should paint it then double shot it, or what order to do this in. Not sure. Maybe i'll just get beige filament. Cursed.

I got this small bench vise to help bending metal before I get the full metal bending brake. SO CUTE. And finally here is a family photo with the big switch, the spring of which is too big. Guess My future 4x scale macro pad will also have a big pale blue switch.

- SneakyRobb

- THINK

- Location: Canada

- Main keyboard: KB-5161A, F122, Dc2014, Typeheaven, Beamspring FXT

- Main mouse: MX518 Legendary

- DT Pro Member: 0242

Hi,

So I printed the new clickleaf and leaf spring shapes vs the ones ive cut. Like the red/black comparisons above you can see the differences!

As well I wondered Why the click leaf was not correct. Turns out my housing model did not have enough width for the click leaf.

I will have the return spring this week and I will then work to getting the actual "contact" part of the switch to work.

So I printed the new clickleaf and leaf spring shapes vs the ones ive cut. Like the red/black comparisons above you can see the differences!

As well I wondered Why the click leaf was not correct. Turns out my housing model did not have enough width for the click leaf.

I will have the return spring this week and I will then work to getting the actual "contact" part of the switch to work.

- Attachments

-

- overlay.jpg (4.83 MiB) Viewed 12258 times