andresteare wrote: 06 May 2021, 20:35

Maybe related with this

lubeRegimes1-e1511148583728.jpg

When the lube is way too thick it creates a separation between the two objects creating a layer of higher friction. Maybe we have now an idea of how much viscosity is too much and we should work on the thickener of the base oil to reduce friction. I was thinking of looking for lubes with PTFE thickener since PTFE is the plastic with the lowest coefficient of friction, hence why I proposed testing Superluber grease. Nye Lubricants have some PTFE thickened products in their portfolio, I'll revisit those TDS and come back. Remember that we are looking for lubricant based on Synthetic hydrocarbons or Silicone, other base oils are not so friendly with plastics.

We're all learning in this, research must go on

Great stuff. I don't think though that the full oil film is responsible in this case. In this case the static friction got higher, which is contrary to what a full oil film "friction" would look like. In my understanding, full oil film should result in almost the same static and dynamic friction. Because if the film oil is really that thick, the surfaces wil actually float on the oil, even when stationary, and therefore will have no binding or any stick-slip behavior, but if the oil makes the friction to go up in general then they would simply be "heavier" to move (press), however they will be

constantly heavier, either when moving or when starting to move. No binding and no stick-slip.

There is something very wrong with the Coefficient of Friction in the case of switches that get binding and stick-slip sliding.

Let me explain. CoF is the ratio of the force, needed to push and slide the surfaces vs the force of the load that they already have against each other (this is any force that makes them press against eachother, e.g., gravity).

CoF ratio of lubricants, or self-lubricated materials is measured in the tenths of 1 (e.g. 0.05, 0.1, 0.15, 0.2 etc), which means that the worst case scenario, as in the "boundary" in the above graph, will still only take a

fraction of whatever force is pressuring them against eachother in order to move it.

The weirdest thing with our case with the switches, is that there is actually no horizontal force that pressures the stem surface and the housing surface together. The stem and housing are standing vertically to the ground, so gravity is acting vertically on them and therefore they are not pressed against each other horizontally by any force, so essentially

they have no load at all. Here is an illustration, similar to the ones in the graph above, but rotated so that it depicts the actual direction and position of the stem and housing surfaces relative to the ground and how gravity acts upon them.

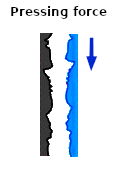

Straight down key press at dead center

- straight-press-stem-housing.png (7.93 KiB) Viewed 8827 times

(the blue surface is the stem and the black surface is the housing)

It is clear that there is no horizontal force that is pushing them together, only gravity that pushes them down. So the surfaces remain apart and the grease/oil that stays in between them

is not pressured at all. So if you manage to press the key completely straight down, the only forces that you will need to overcome with your finger is:

1) the spring that is pushing back up, exerting a

vertically force and therefore does not influence the horizontal positions of the two surfaces and

2) the friction of the click and contact leafs that are touching the stem and pushing against it.

So in the case of a straight press, there is actually only the friction of the click and contact leafs.

And in conclusion, the Coefficient of Friction

is in this case, completely irrelevant, simply because there is no load whatsoever between the stem and the housing, so the

CoF of 0 load = 0. (I hope this makes sense.)

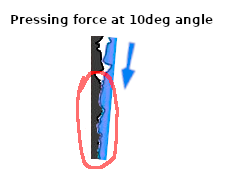

Having said that, lets now examine the more interesting case: the angled (corner) press.

Angled press (corner press)

- angled-press-stem-housing.png (10.86 KiB) Viewed 8827 times

When you press the stem

at an angle instead, then the stem will lean a little bit and eventually the stem and the housing will get in contact at some point. This will result both in getting them to rub together (dynamic friction) but also, and even worse, at the lowest point of contact, the surface of the stem will actually dig in to the surface of the housing, and

they will get stuck.

This is how a key "

binds". It literally gets stuck into the other surface, and in order to overcome that, you will need to press it so hard, that the force that you will exert

will be in to the hundreds or thousands of times more than their horizontal load force. And remember, the horizontal load force is actually 0 in this case.

(so to be exact, any number above 0 is infinitely bigger than 0, so this means that you exert an infinitely more amount of force.

)

In conclusion, also in this case the Coefficient of Friction of the oil is irrelevant, precisely because the two surfaces have come in to contact and the oil

has failed to keep those surfaces apart, So, 1) the only Coefficient of Friction that matters in this case is the one between the two plastic surfaces, which is way, way higher than

any oil and 2) the surfaces not only are touching but they have actually got "merged" together and have gotten stuck, so

even their CoF is irrelevant when this happens.

Therefore, in order for an oil/grease/lubricant/whatever to successfully prevent the binding, it must be strong enough so the surface of the stem at that point will not penetrate it and will not therefore penetrate the surface of the housing. This will keep them from getting stuck, or "bind".

I had the knowledge that Viscosity is the primary factor of how strong an oil is, and therefore the more viscous, the more it will defend and prevent the penetration of the surfaces.

However, it turns out that viscosity alone is not the only thing that matters, this is where I was wrong. It probably is how well the oil is adhering to the surfaces as well.

The answer in my question in the Chemistry Stack Exchange, gave some light to the issue.

It may be how well the grease/oil adheres (sticks in) to the plastic surfaces! That really makes sense now, because the OKS 1110 is Silicon Oil and OKS 477 is PAO. So maybe PAO adheres much better and/or strongly to these plastics, so it doesn't matter how more viscous the former is, it simply just doesn't work.

I have commented on that answer and updated my question and wait for more answers, lets wait and see if we get more answers from them.