It is the switch that IBM intended to replace their common Selectric-based terminals, providing tactile key feel and relatively low force. It's a fairly complex switch, with three springs, and quite a few moving parts. Supposedly, it's quite durable in use, but it can be quite fragile to work with, and it's certainly costly to assemble.

Buckling spring came into production about 8 years later, as a lower cost replacement for beam spring. Overall force was increased from 55 g (according to patent GB1363777, originally filed in the US (and presumably rejected) 1971-09-24) to about 70 g (according to patent US4118611, originally filed 1977-08-30). However, initial force was reduced from 45 g to 30 g. The tactile event was also enlarged - immediately after the tactile event, a beam spring is rated at 45 g, for a 10 g reduction in force, versus capacitive BS at 50 g, for a 20 g reduction in force - doubling the tactile feel.

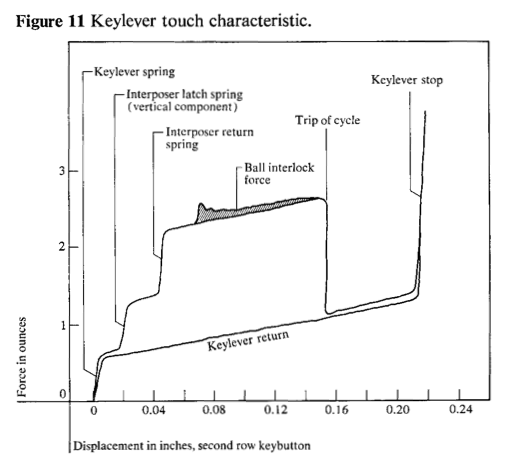

For the sake of completeness, here are the beam spring and capacitive buckling spring force graphs:

Beam spring:

Buckling spring:

This is actually much closer to how a Selectric key feels, although the Selectric also has some elements that make it more similar to a Cherry MX Blue in ways.

In any case, I have reason to believe that beam spring was merely a stop-gap until buckling spring was ready for production.

See, 4118611 was not the original buckling spring patent - it was merely an enhancement of US3699296, filed 1971-05-21 - that's right, BEFORE the beam spring patent.

This patent is on the original spring contact form of BS, which was never produced. However, the force graph shown (which isn't measured in units) shows extremely low initial force ramping quickly to a high peak, and then a very sharp tactile event. Preload on the spring is 25 grams, so we do have an EXTREMELY low initial key force, but no other figures are given. Good key feel and hysteresis are mentioned as reasons for the design of this switch, along with durability and simplicity. However, we know that this technology was never produced - presumably, spring contact was too unreliable, and the other suggestions for making it work (capacitive sensing ala Topre, piezoelectric sensors detecting the impact, or optical sensing) would likely have been too expensive.

This switch, however, sounds like what IBM and Richard Hunter Harris were really going for. Beam spring was produced because it was possible with the technology available at the time (the capacitive BS switch requiring a lot of fine tuning on the injection molds that beam spring did not need), and it was still a lot cheaper than using Selectric mechs like IBM was doing. But, buckling spring offered lower initial force (which I find is an important part of reducing fatigue), sharper tactility, and lower cost once the alternate method of actuation that IBM ultimately used was found.