Produce a full DROP-IN REPLACEMENT for the model M by retooling all the inner workings into a completely replicated F (while keeping the key layout of the M).

This means that we could leave our existing M assemblies intact (no modification or bolt-modding), and literally open the outer shell, pull the existing assembly with attached controller out, and drop-in the new unit. Seal the shell back up, plug-in the USB (no adapter), and go.

This has all been made possible by the work i$ did to create a capactive PCB for the model M (code named FSSK/FEXT), which replaces the existing membrane. For that project, we have been able to use F flippers/springs inside our M barrel frame with minimal changes.

This workshop is extending the journey to further the experience towards the REAL objective (a true model F switch with a model M key layout and form factor)... At least it's my "Holy Grail"

We originally 3D printed all of these designs to validate the approach, and proceeded through a series of metal prototypes with minor adjustments to finally arrive at a quality product for both the SSK and full-size (101-key). We have had multiple contributors along the way (WCass, Phosphorglow, Techno Trousers, and obviously i$) that have made all of this possible.

If you decide to read through the thread from scratch (good luck), there will be a mention of Phase 1 and 2:

- Phase 1 is the drop-in replacement for the Model M inner assembly that turns a Model M into a functional F. The only parts remaining from the original M are the outer shell (case), and the keycaps.

- Phase 2 is to be determined, but we would be making a new and unique board from scratch using a new buckling spring switch (hopefully improved) that would support modern layouts, keycaps, case designs, etc.

Phase 1 will be sold as a "kit" (ala-carte in case there are portions of the kit you don't need) for both the SSK and full-size M:

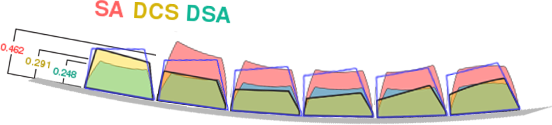

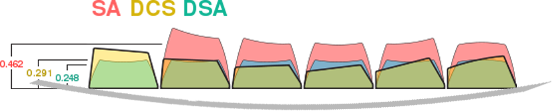

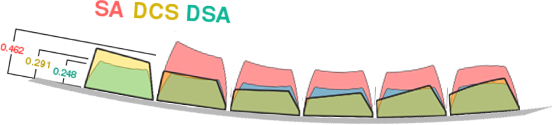

- Steel assembly top plate powder coated (with a stainless steel limited edition) that accepts either XT or AT style F barrels in a standard Model M layout. Powder coat colors will be black, industrial SSK blue, green, orange, red, and yellow. There is only one version of the plate that includes additional cut-outs for OPTIONAL keys, where unused keys can be capped to prevent debris):

- winkeys - between Ctrl and Alt on either side of the spacebar

- Split spacebar - using a right shift, "Code" key from a Wheelwriter, and a Ctrl/Alt key, the spacebar can be split into 3 keys (two 2.25u and one 1.5u)

- Steel assembly backplate offered in yellow chromate and powder coat (with a stainless steel limited edition)

- PCB derived from i$'s FSSK/FEXT project with only minor changes to allow for optional keys and solderless "slip-on" controller. The PCB will be offered in green/white (SSK)/black (full-size) color options

- mini xWhatsit Controller modified by WCass using a solderless connection that will be offered in green or black. The controller leverages a daughter USB board for case exit that will be offered in USB-B, USB-C, USB-micro, and USB-mini female port connection options

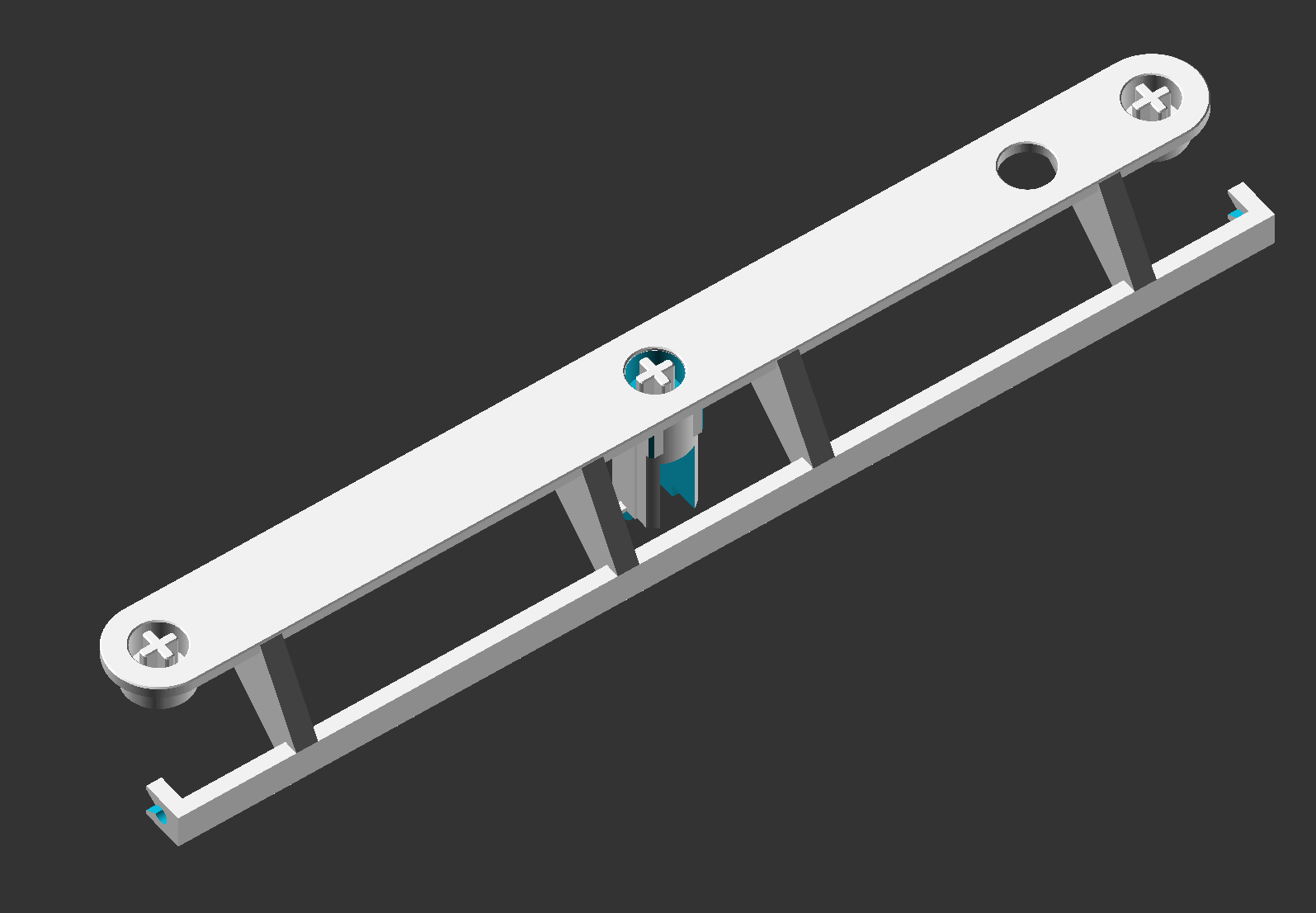

- USB port retainer clip that holds the daughter board in place and covers the empty space left by the SDL connector

- "Foam" layer that has been redesigned to both stabilize the keys, eliminate unwanted audible feedback, and better seal the assembly from debris

- Stabilizer clips with an updated design to cradle wire stabilizers on both horizontal and vertical keys throughout the board (where needed)

- Fasteners for bonding the plates and sealing the assembly, with o-rings provided in areas that would be tension sensitive like the middle of the board

- Switches (includes the spring, flipper, and barrel) will not be produced in Phase 1, but so far we have managed to salvage enough switches with Cindy's help to supply approximately 50 boards. It is the one limited commodity of the GB.

When the GB for Phase 1 commences, it will be a separate Marketplace thread (I'll make sure to post it here for awareness). I expect the GB to run for around a month (or longer if the salvaged switches aren't spoken for). We might open the doors up to GeekHack at the end once the switches are gone.

Everything below are portions of the original post here showing the original plastic printed parts and CAD renderings to produce everything. We have made significant progress since then, but keeping here for posterity. See the first 5 posts in this thread for a fully captured history of events with updates.

________________________________________________________________________________________________

Enough yik-yak, time for photos

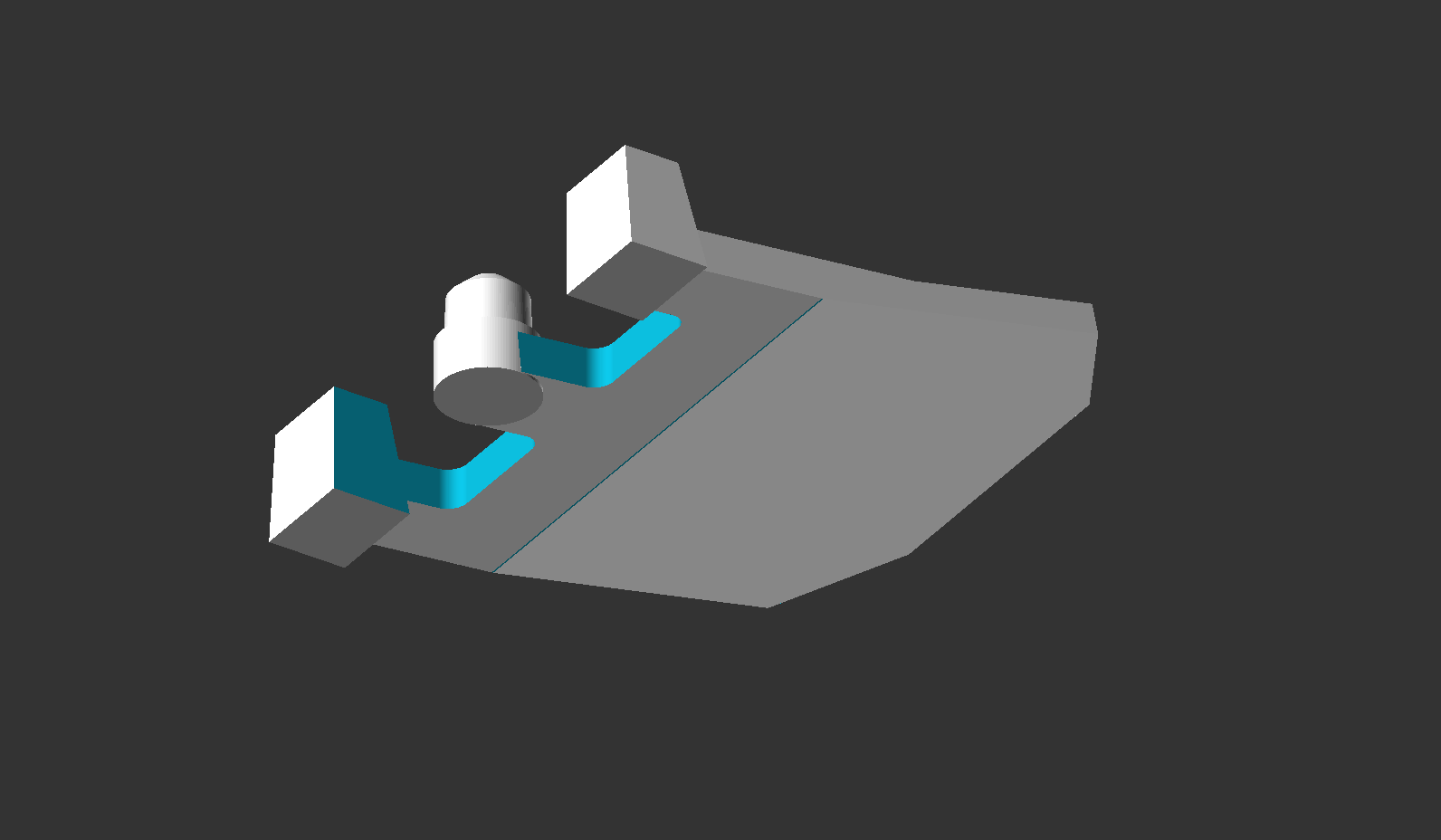

CAD renderings for everything (so far). Most have been printed, and confirmed working

- Top PlateSpoiler:

- Back PlateSpoiler:

- AssemblySpoiler:

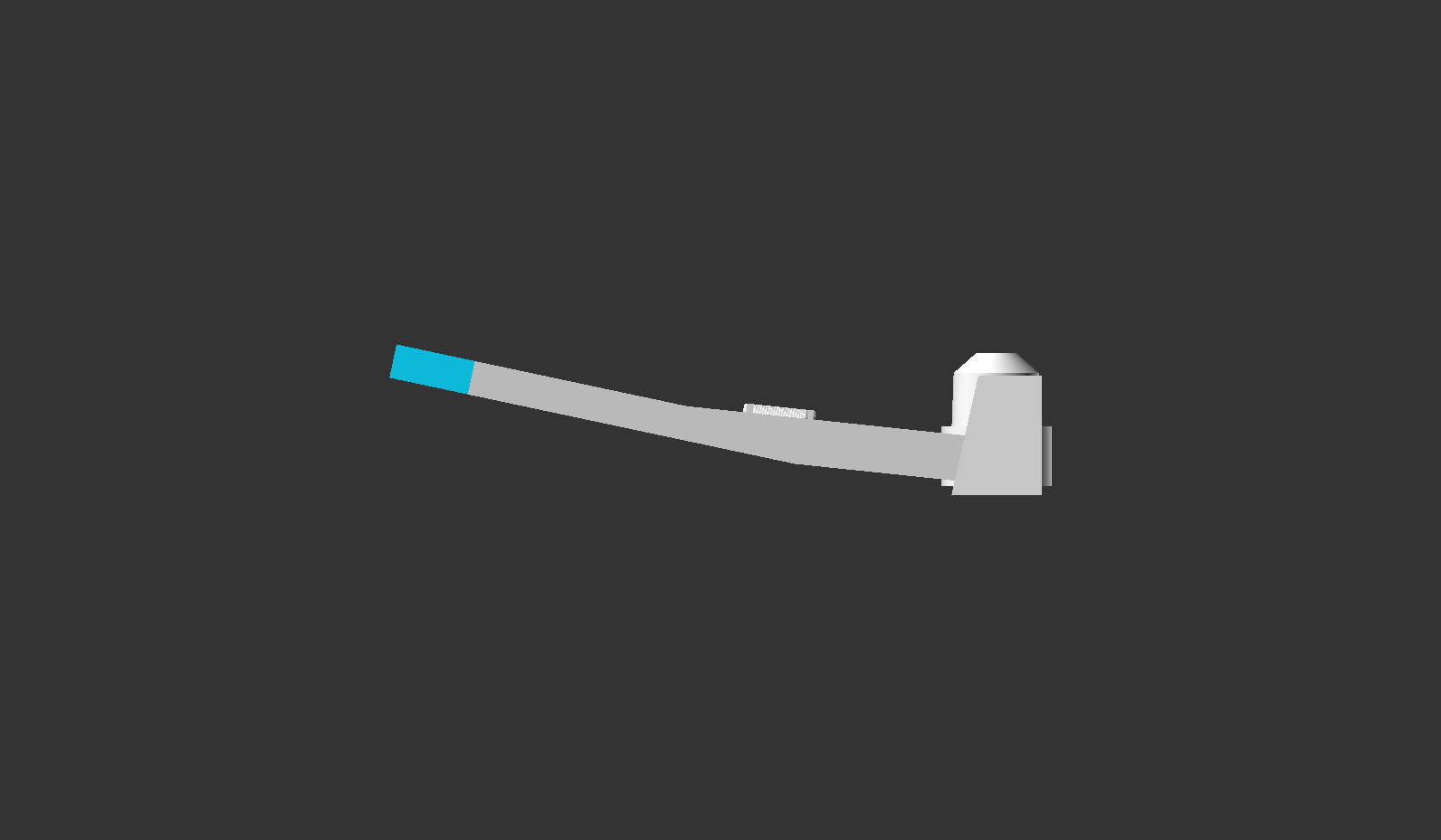

- BarrelSpoiler:

- FlipperSpoiler:

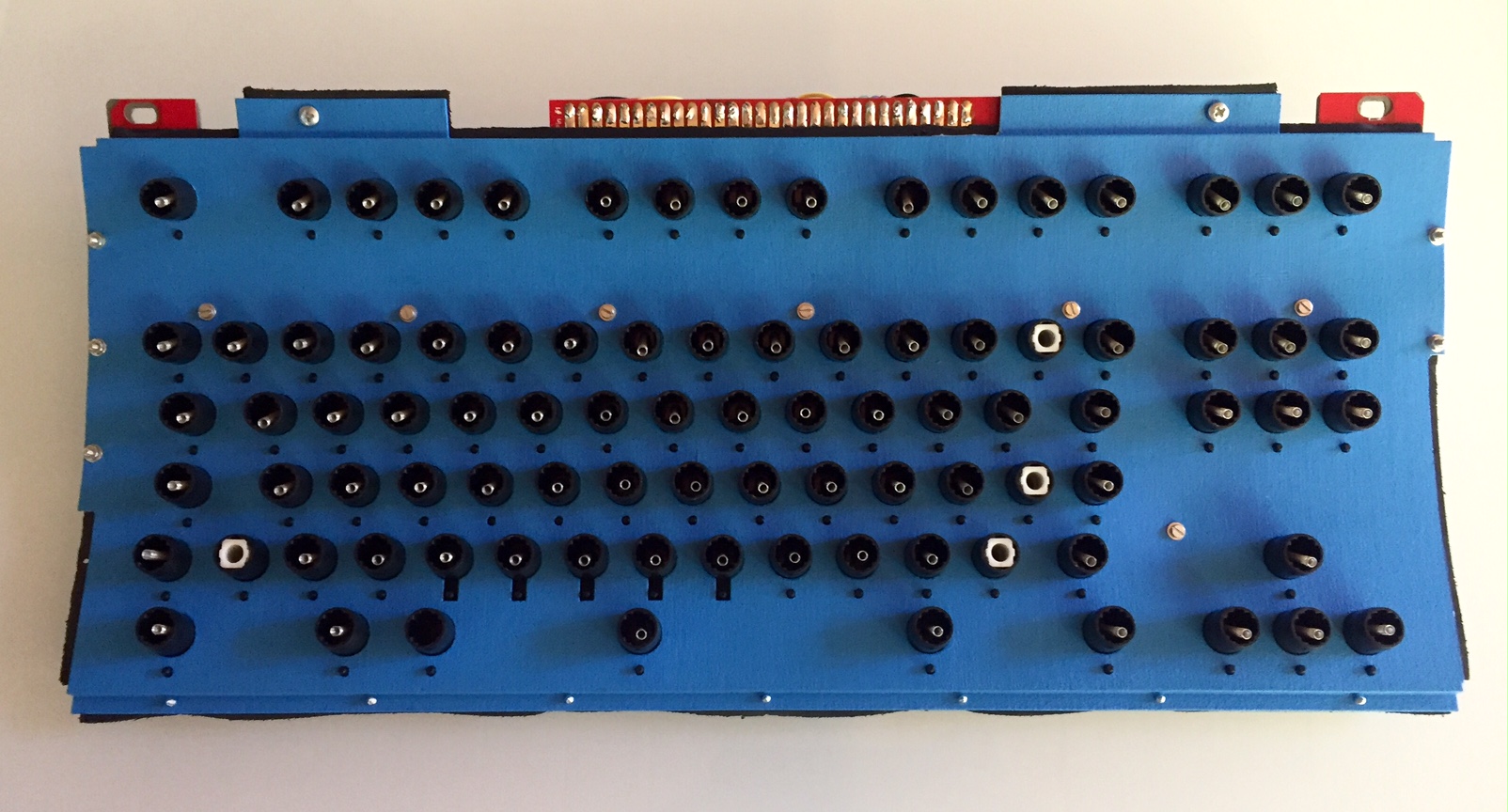

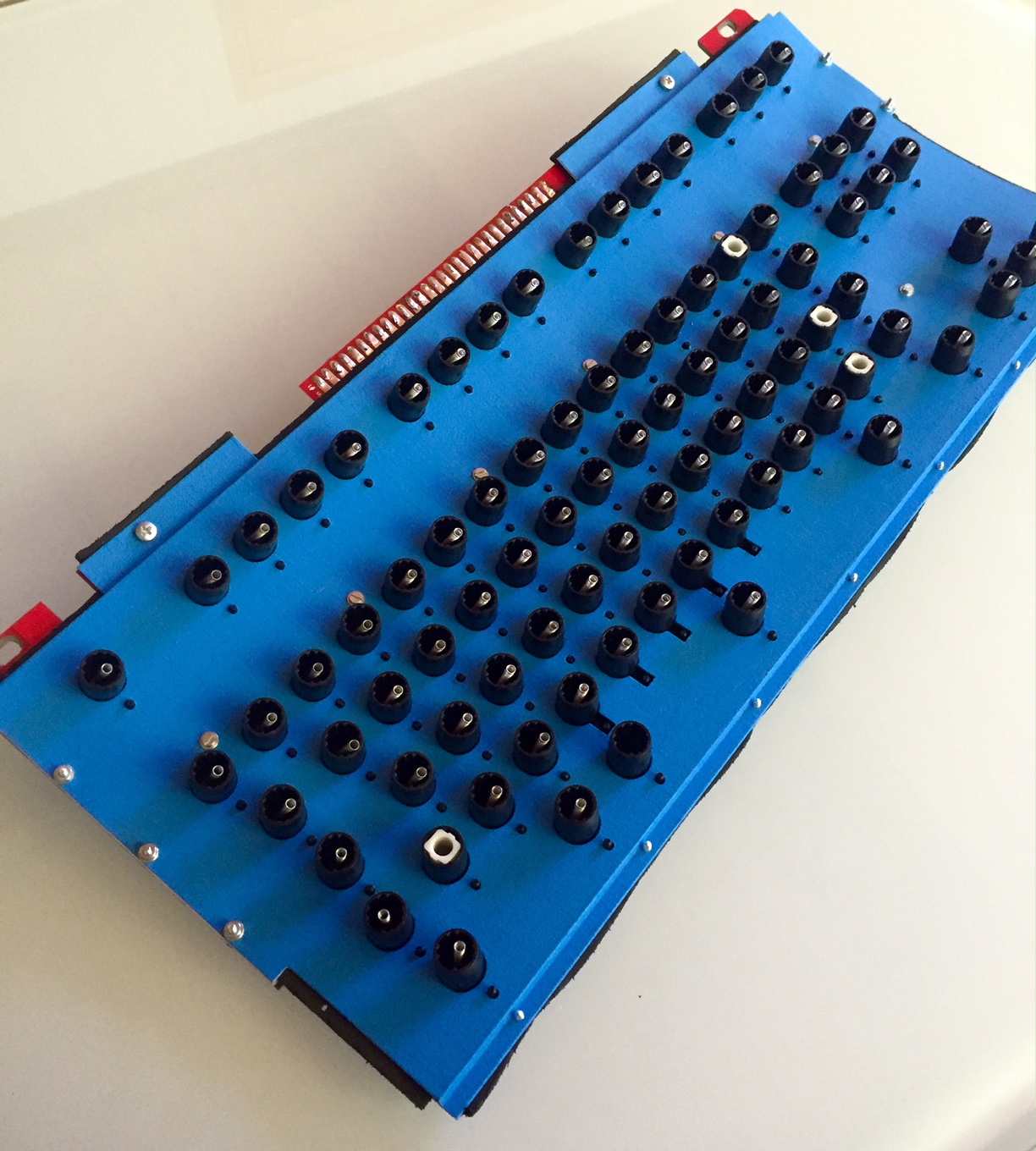

Photos of the Printed (functional) Prototype

- Printed PartsSpoiler:

- AssemblySpoiler:

- ResultSpoiler:

Flipper bottom

Flipper bottom Side view of the flipper to note the two step angles

Side view of the flipper to note the two step angles Flippers, stabilizers, and additional screws added to the design since this plastic was so flimsy (I can easily fold each plate in half before assembly)

Flippers, stabilizers, and additional screws added to the design since this plastic was so flimsy (I can easily fold each plate in half before assembly) Assembled unit with i$'s PCB

Assembled unit with i$'s PCB

The fully functional prototype with single piece caps borrowed from a 1397681. The little odd "blue key" as Enter/Return is the initial Cherry MX adapter I had printed a while ago. There for nostalagia, and a reminder of what is coming

The fully functional prototype with single piece caps borrowed from a 1397681. The little odd "blue key" as Enter/Return is the initial Cherry MX adapter I had printed a while ago. There for nostalagia, and a reminder of what is coming