EDIT: only the spacebar stabilzer barrel is unsupported at the moment

Oh wow, a FSSK with winkeys! That's awesome. When can be buy the drop-in-replacement?lot_lizard wrote: I have updated the OPs with the updates for the metal plates and final deliverable for phase 1 (the drop-in). There is quite a bit there... so be ready for a long read. Click the link below to proceed (with caution)

workshop-f7/remodeling-the-model-m-t137 ... ml#p308668

Teaser... Long story short... Only mild tweaks... IT'S ALIVE

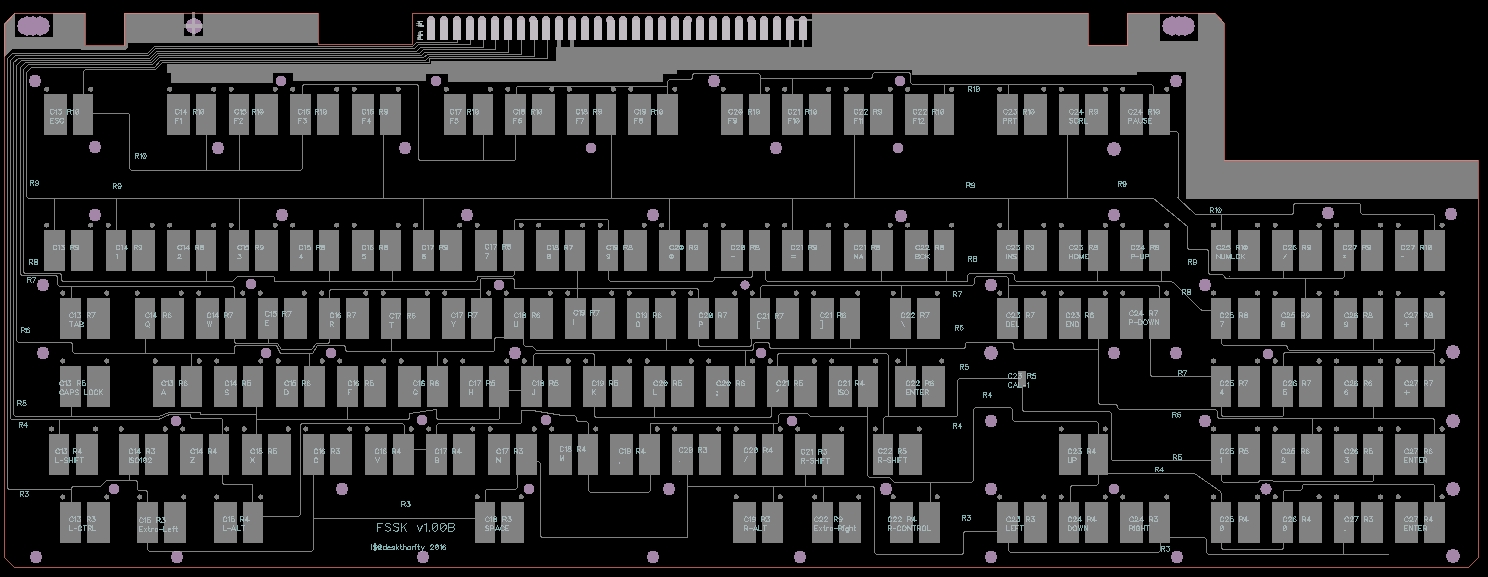

Hate being the bearer of bad news, and I should have mentioned in the OP, but the winkeys don't have pads in the original FSSK. I realized after I was clacking away and wondered why they weren't registering. He has in the FEXT, and will have when we finally decide to group buy this stuff. I have all the quotes in except the plastics. I'm still waiting on my "dead beat" lab to give me the makeup of the flippin flipper

I have the metal already processed for the FEXT. It's next. In version two of the PCB, he will slide the pads over slightly, but I have tested manually, and your v1 PCB will still work. The flippers can have substantially less contact and still register nicely. The v1 FEXT is good to go for winkeys as is. The FSSK will require another run. Keep in mind though, your model M shell will need to be modified to take advantage. There is a reason the outer top shell isn't on in my pics. Everyone was just interested in the winkeys, so I showed the alignmenttentator wrote: So my doubt is that if I want to use an FEXT on an unicomp to make use of the winkeys (a metakey left and a fn key right) which I'd really like to have (split spacebar and menu keys are really not a must), then I think that since on a regular M it seems there is almost just space for an 1u key then the FEXT PCB will not really have the right alignment for the 1.25u keys.. ok maybe they still register but this I will only know by trying as soon as I can do the test with a FEXT (hope soon).

That is the old Unicomp layout, and they eventually abandoned it. I believe that any PCBs i$ makes will just slip a 1U sensing pad, between 1.5U positioned sensing pads for CTRL and ALT.

I didn't follow you were in a Unicomp case until after seeing alh84001's response. You should be fine. Model M's have a portion of the shell filling that winkey void. To use, a Model M top shell would need to be altered to make room for the key. The xWhatsit and PCB have no impact on any configuration

We are a bit away from v2 PCB and the group buy phase 1 I think. But I'm not sure what "bit" means just yet. The metal plates are set with the changes I will make and publish in the coming days. We want to take advantage of the modified mini xwhatsit that wcass made as a model M controller drop-in (still needs to be tested). It is based on a .1 inch pitch cable (standard ribbon cable... Think IDE). With it, we should change the PCB connector to match for v2 (reduced cost of assembly). I will finish receiving quotes over the coming days/weeks for flippers and barrels, and will finally have a ball park number to hand out.Techno Trousers wrote: Is it too early to talk about trading my v1 FSSK PCB to someone in exchange for a v2 when they are produced? I really want the windows keys, and don't mind modifying my case (or better yet getting a new metal case eventually). I know there are folks out there who don't want to modify their case, and/or don't care about the extra win keys...

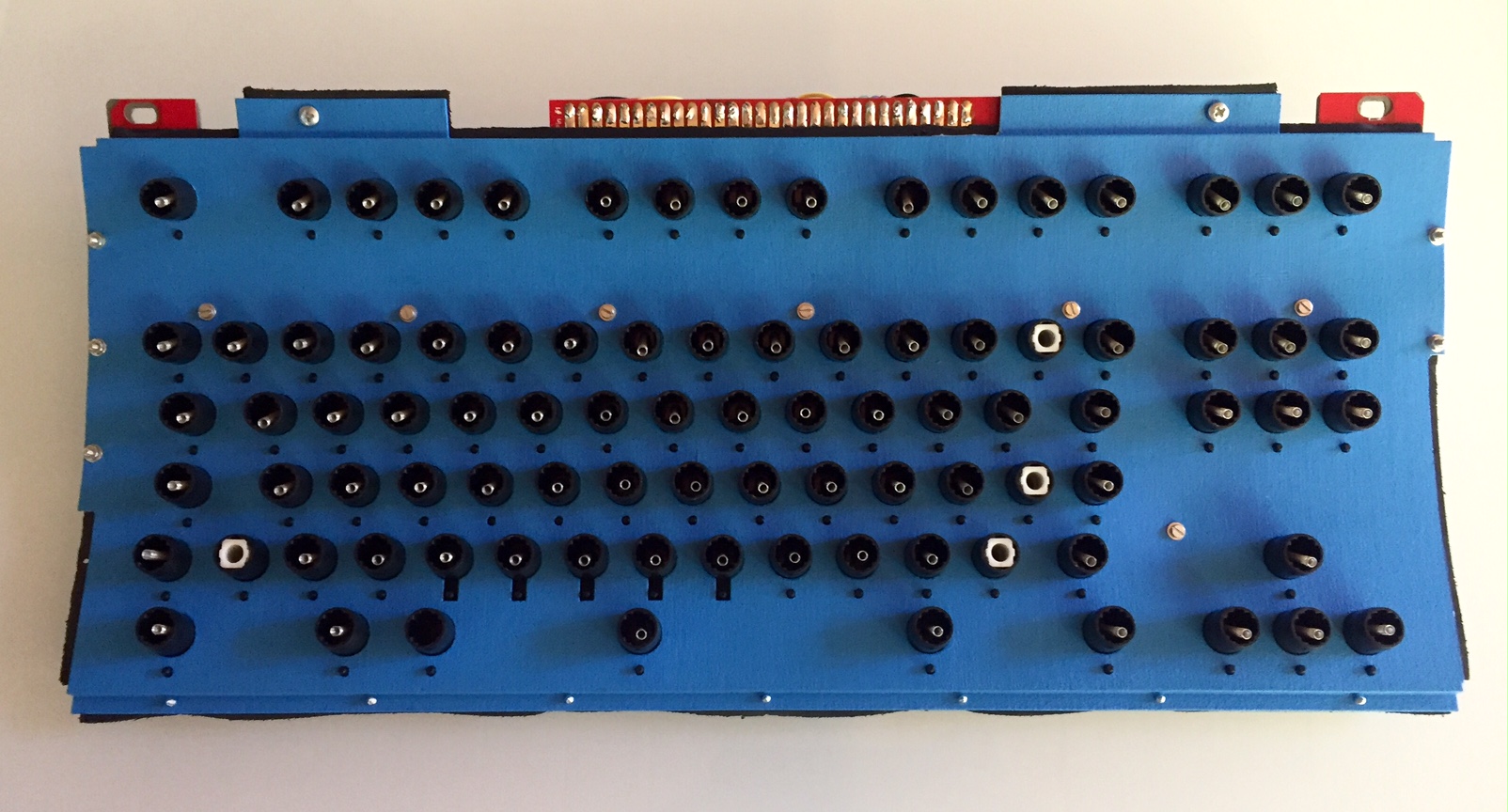

I have been typing on this now since mid-Saturday, and there is definitely a slight change in pitch between the key rows. Bending the top plate to be tighter definitely had positive impact (almost eliminating it), but since I now have sound OCD (thanks guyspyrelink wrote: Question about the newest prototypes, how do the keys in the very center of the board feel? I know that when replacing the foam on one of the larger OG model F's that is pressure fit together, the keys in the center of the keyboard were always wobbly and more ping-ey. As this board is only being held together with perimeter screws, how well is the center being compressed, and how do those keys feel?

Yeah, an IBM logo on something IBM didn't make would be pretty cheesy too. I'm not a graphic artist though, so I can't help much to keep this dairy-free.

Hello, I may be temporarily backlot_lizard wrote:Hate being the bearer of bad news, and I should have mentioned in the OP, but the winkeys don't have pads in the original FSSK. I realized after I was clacking away and wondered why they weren't registering. He has in the FEXT, and will have when we finally decide to group buy this stuff. I have all the quotes in except the plastics. I'm still waiting on my "dead beat" lab to give me the makeup of the flippin flipper