Looks good to me. I've stripped down more Topre boards (to install silencing rings) than Model Fs so I’m very familiar with an obsessive looking amount of screws. Sure you don't want some in the middle? It's super satisfying when you do them all back up again.

Modeling an F key mechanism

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

ah, yes, topre. But I kinda outdid even them - topre has 30 self-tapping screws, and this one has 39 _pairs_ (granted, top screws will never be unscrewed, but someone will need to assemble it, and 78 screws, each needing 18 full turns is a bit cruel, even with powered screwdriver).Muirium wrote: 01 Jul 2023, 11:44 Looks good to me. I've stripped down more Topre boards (to install silencing rings) than Model Fs so I’m very familiar with an obsessive looking amount of screws. Sure you don't want some in the middle? It's super satisfying when you do them all back up again.

Can't have anything in the middle - keys are too close together. It has to be at most M2, with a self-clinching nut on the bottom - and even then it will provide a mechanical linkage from barrel to the plate, causing a lot of sound leakage.

OTOH, top plate will be 1.5mm of 304/316/904 steel, I don't think it will noticeably bend, even considering all those cutouts. And if it will - it's probably easier to press some ribs into it for extra rigidity.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Just remember to mark the PCB with those cool arrows or at least the circles, as they really help when you're down to your last few screws. I know!

Well, I suppose in Model F's and your case they go from plate to plate, which is harder to mark, but also much more self-explanatory. PCBs are visually much busier.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

yeah, the back of the keyboard is pristine, nothing but bolts. Circles and arrows make sense when some bolts are there to fasten the lid to the case, and some are to fasten something else to the lid - but it isn't the case, plus there are countersinks which are CONSPICIOUSMuirium wrote: 01 Jul 2023, 14:40 Well, I suppose in Model F's and your case they go from plate to plate, which is harder to mark, but also much more self-explanatory. PCBs are visually much busier.

-

Liamkrum

- Location: Southern California

- Main keyboard: GMMK Pro, Model F

- Main mouse: Ninjutsu Sora

- Favorite switch: Buckling Spring

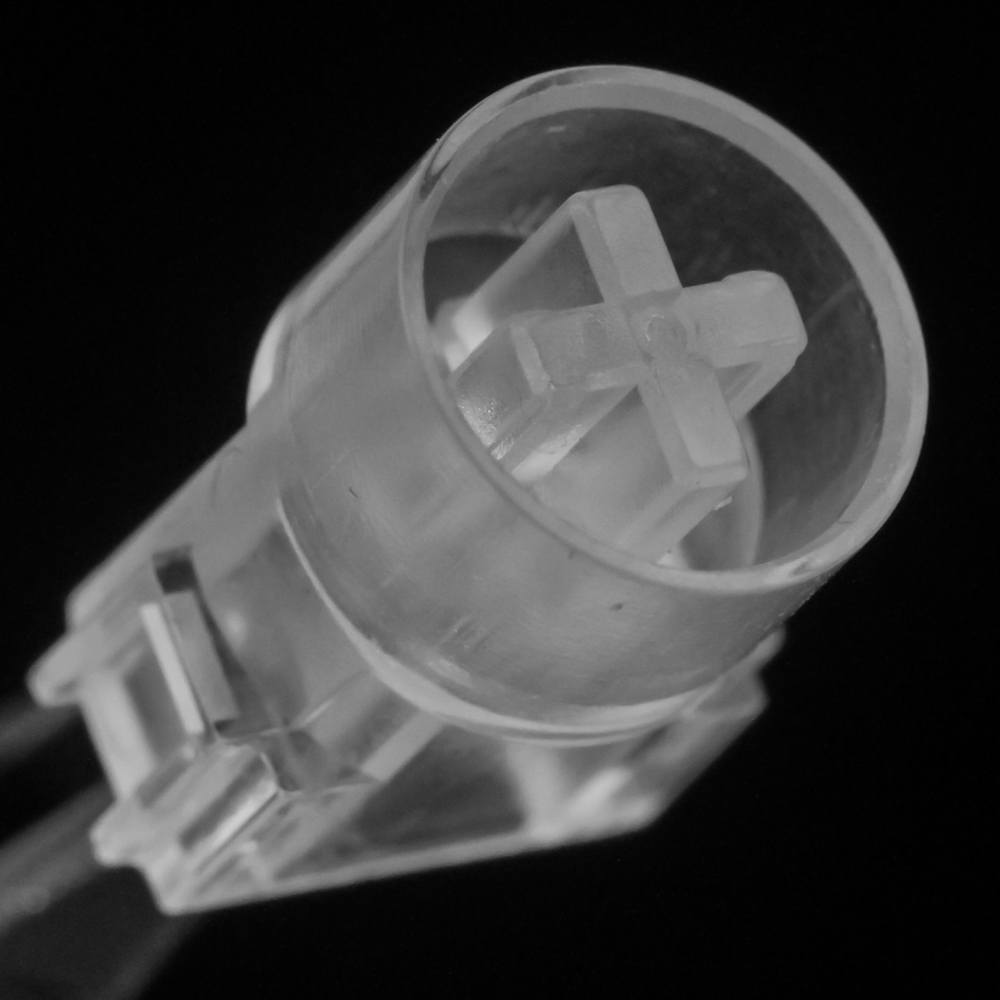

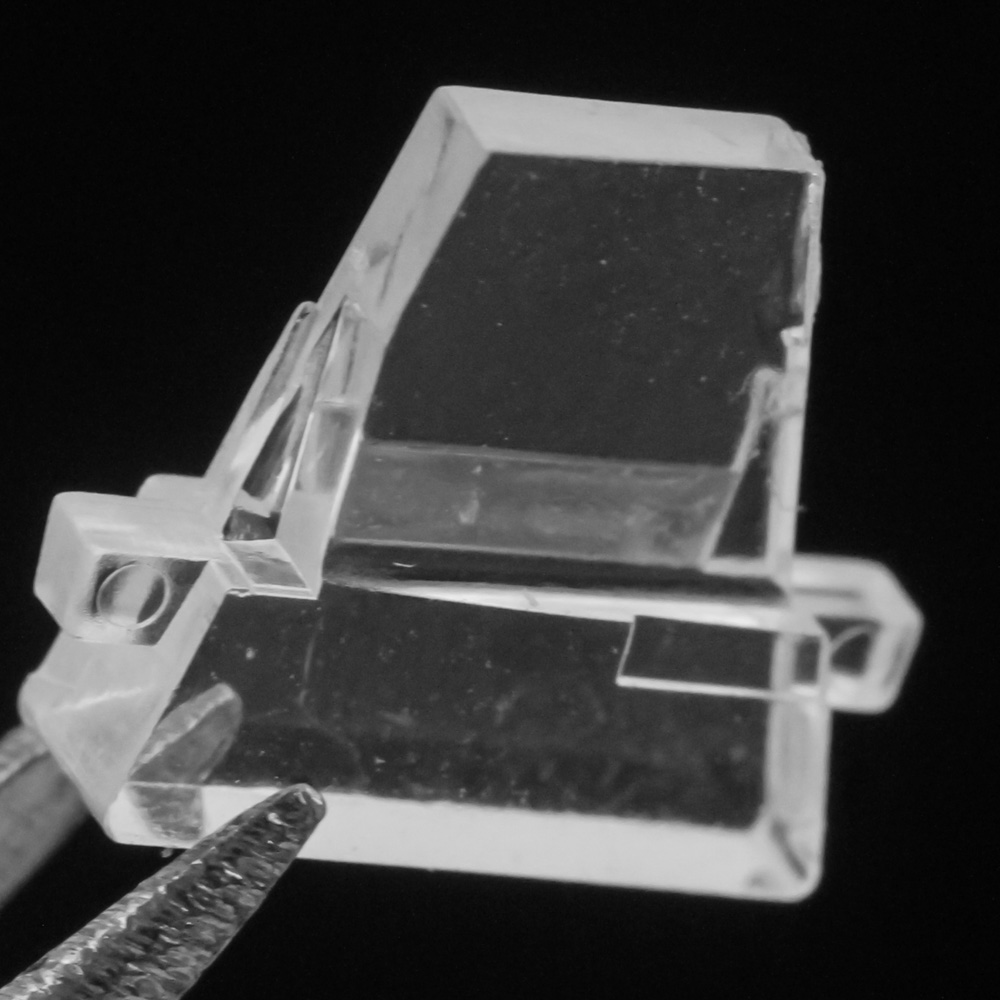

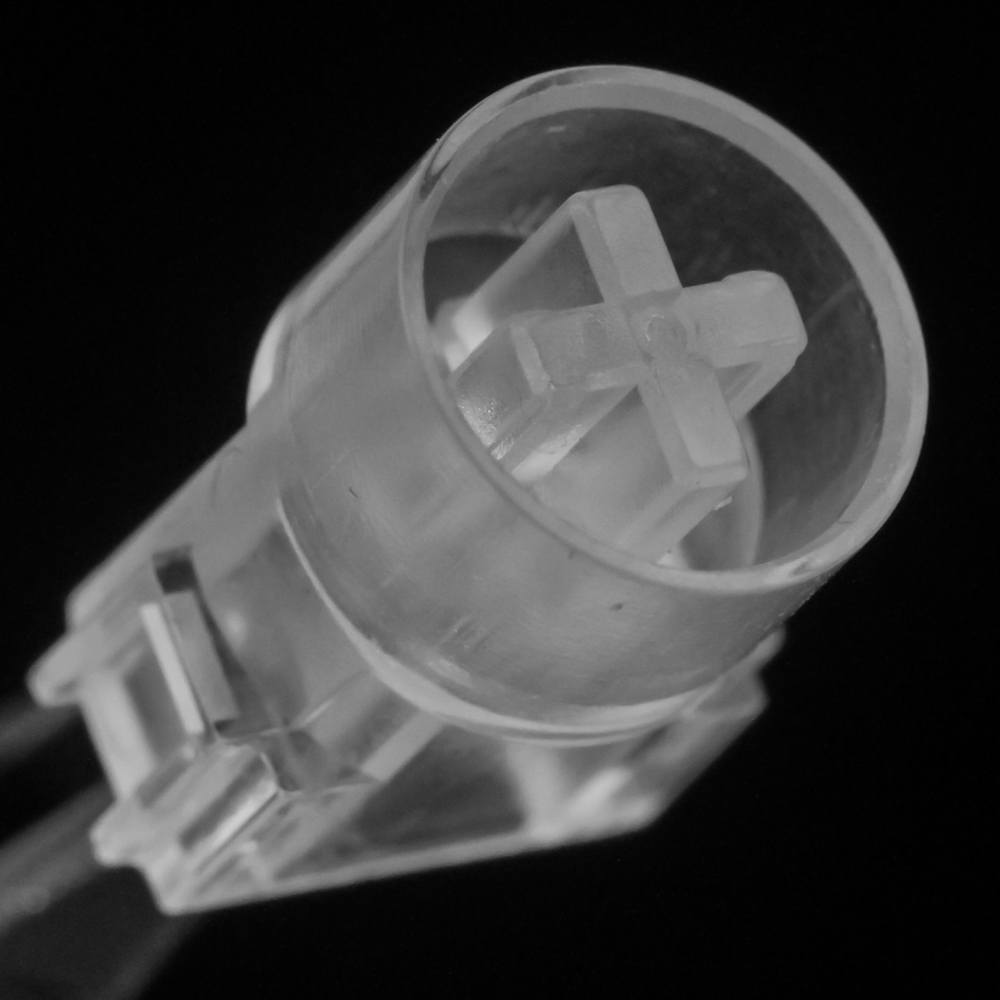

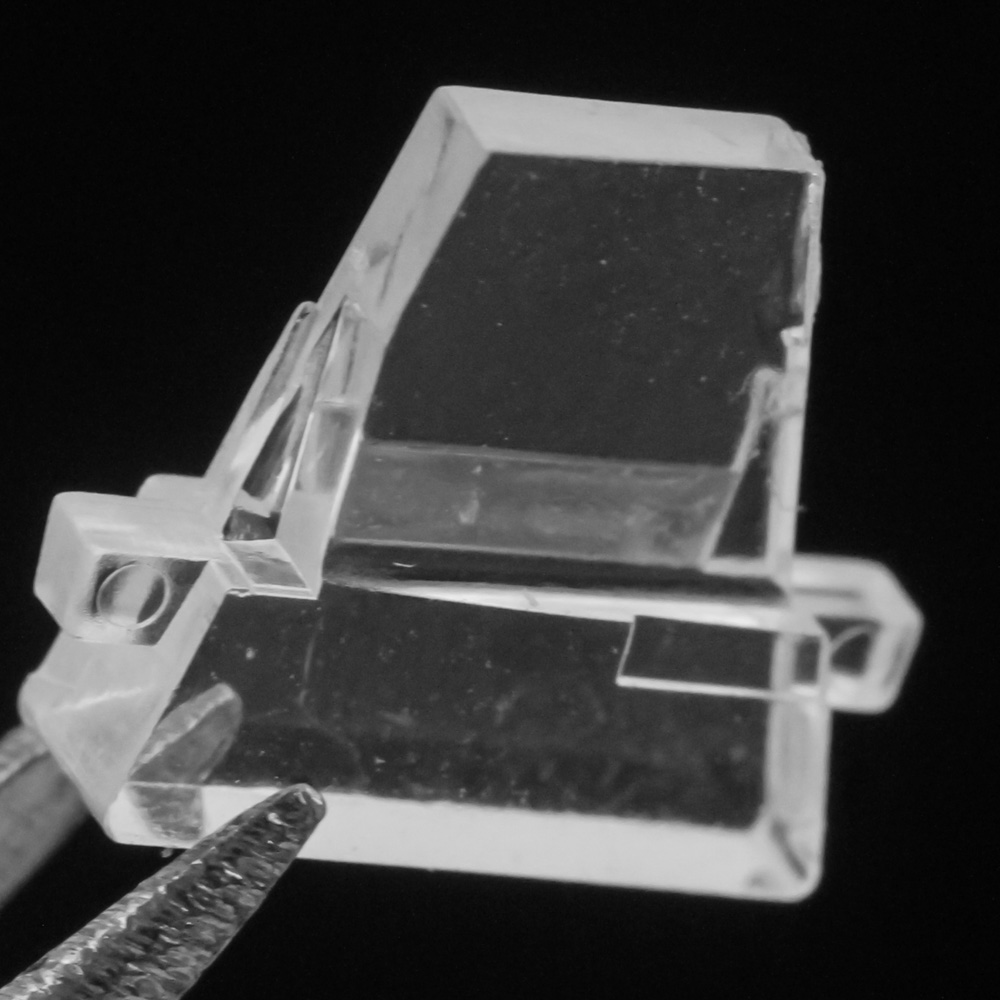

Something I've noticed about your design here: By thinning the edge of the barrel so much, you seem to be leaving about 0.1-0.2mm thick of plastic in between the outsides and the notch of the keycap. With a bit of wiggle, it might be able to tear through that thin sheet of plastic. It also seems incredibly difficult to 3D Print without some kind of 0.2mm nozzle or a resin printer. I don't think you can "square" it up so much with how thin you left it. Seems like its a circle shape for a reason.DMA wrote: 18 May 2023, 06:23 Wasn't easy, but here it is - 19x19mm, MX-mount, LED-enabled, original stem- and flipper-compatible buckling spring assembly, free of that pesky "spring doesn't buckle and requires reseating" bug.

f-assembly-final.png

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

yeah, because nothing is touching the barrel there, wiggle or no wiggle. I'm pretty sure every part that touches anything (temporarily or not) is at least 0.5mm thick - but I'll check.Liamkrum wrote: 05 Jul 2023, 06:31 Something I've noticed about your design here: By thinning the edge of the barrel so much, you seem to be leaving about 0.1-0.2mm thick of plastic in between the outsides and the notch of the keycap. With a bit of wiggle, it might be able to tear through that thin sheet of plastic.

It will indeed be stupid to use 3d printer for that - but it won't be used, those parts are designed to be injection-molded.Liamkrum wrote: 05 Jul 2023, 06:31 It also seems incredibly difficult to 3D Print without some kind of 0.2mm nozzle or a resin printer.

Not really.

-

Liamkrum

- Location: Southern California

- Main keyboard: GMMK Pro, Model F

- Main mouse: Ninjutsu Sora

- Favorite switch: Buckling Spring

Hmm, looking at the file you sent, the edge seems really thin (definitely less than half). I measured the edge of a barrel I have lying around at 1mm, so considering that the wall hardly seems like a few pixels in your screenshot, I wouldn't have much faith in the durability of this if you wiggle the cap a bit too hard to the side. Those "holes" seem like a non issue, but a cap that is sideways could easily get stuck in these created "holes". Not a manufacturing or plastics expert though, if someone is here, feel free to weigh in.DMA wrote: 05 Jul 2023, 06:57Something I've noticed about your design here: By thinning the edge of the barrel so much, you seem to be leaving about 0.1-0.2mm thick of plastic in between the outsides and the notch of the keycap. With a bit of wiggle, it might be able to tear through that thin sheet of plastic.

yeah, because nothing is touching the barrel there, wiggle or no wiggle. I'm pretty sure every part that touches anything (temporarily or not) is at least 0.5mm thick - but I'll check.

Makes sense. Although is it possible to mould a wall that thin? With a quick google search, it doesn't seem like you want any part thinner than 1mm.Liamkrum wrote: 05 Jul 2023, 06:31 It also seems incredibly difficult to 3D Print without some kind of 0.2mm nozzle or a resin printer.

It will indeed be stupid to use 3d printer for that - but it won't be used, those parts are designed to be injection-molded.

Makes me wonder why the designers made it a circle... I guess it just adds on to the point that those mould makers really were showing off lol.

- Attachments

-

- firefox_YUsEVC5dWp.png (62.45 KiB) Viewed 19633 times

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

again, you literally can't wiggle anything to contact that part.Liamkrum wrote: 05 Jul 2023, 08:25 Hmm, looking at the file you sent, the edge seems really thin (definitely less than half). I measured the edge of a barrel I have lying around at 1mm, so considering that the wall hardly seems like a few pixels in your screenshot, I wouldn't have much faith in the durability of this if you wiggle the cap a bit too hard to the side. Those "holes" seem like a non issue, but a cap that is sideways could easily get stuck in these created "holes". Not a manufacturing or plastics expert though, if someone is here, feel free to weigh in.

Yes, it's 0.15mm thick in lowest 1.7mm - but I fail to see how it matters. That part can be easily made thicker - it's below the LEDs anyway - I just don't really see why.

I've seen a lot of plastic parts thinner than that (in their thinnest part). You also can do that, if you just look around instead of google searches.Liamkrum wrote: 05 Jul 2023, 08:25 Makes sense. Although is it possible to mould a wall that thin? With a quick google search, it doesn't seem like you want any part thinner than 1mm.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

..easy change tho:

I needed to round the sharp corners anyway to encheapen the CNC-machining both the mold and the top plate.

I needed to round the sharp corners anyway to encheapen the CNC-machining both the mold and the top plate.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

The only place you need space for LEDs is above the numpad.

Bear in mind where LED backlight compatible MX caps expect the LED to be. In supporting them, you're lumbered with putting it close to where MX does, and specifically: in the orientation these caps expect…

It's still standard practice to mount MX LEDs at the back, right?

Bear in mind where LED backlight compatible MX caps expect the LED to be. In supporting them, you're lumbered with putting it close to where MX does, and specifically: in the orientation these caps expect…

It's still standard practice to mount MX LEDs at the back, right?

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

There's screenshot of the stack somewhere in back posts. The bulge will be buried in the foam (and possibly MLV, but I'm not so sure about MLV anymore after reading soundproofing forums (they are worse than audiophile forums, so the only thing I really know now is "needs testing"). The LEDs will reside on a separate PCB right under the top plate.Liamkrum wrote: 06 Jul 2023, 08:52 Seems like a good fix. Wouldn't that leave less space for the LED though? How do you plan on mounting that anyways?

Muirium, there's no standard on LED placement in MX. Some put it above, some put it below, some use light pipes to deliver the light where they want.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Light pipes? I’m familiar with the general concept, but haven't seen it used on mechanical keyboards. Got a link / pics?

I’m thinking about what such transparent plastics would look like in your design.

I’m thinking about what such transparent plastics would look like in your design.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

https://www.techpowerup.com/review/kail ... hes/5.html - top left pic, middle pieceMuirium wrote: 06 Jul 2023, 17:05 Light pipes? I’m familiar with the general concept, but haven't seen it used on mechanical keyboards. Got a link / pics?

I don't think I'll use those - 87 extra pieces to manually press in isn't cheap, plus I'll need to separate light pipe holes from barrel cutouts, which will lead to a very thin wall between those, and thin walls are bad. Yes, the crud falling into LED wells is also bad, but without light pipes you can just blow the crud out of the wells - and with light pipes you'll likely blow those under the pipe, ruining everythingMuirium wrote: 06 Jul 2023, 17:05 I’m thinking about what such transparent plastics would look like in your design.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Ah: transparent slider. Pretty cool.

A lot of bother for necessarily shitty backlit caps. But everything about LED backlighting on a mech (rather than a laptop where it belongs) is a lot of bother for nothing much.

A lot of bother for necessarily shitty backlit caps. But everything about LED backlighting on a mech (rather than a laptop where it belongs) is a lot of bother for nothing much.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

It's a molded part, so the form doesn't really matter - same amount of work for any form.Muirium wrote: 06 Jul 2023, 22:32 A lot of bother for necessarily shitty backlit caps. But everything about LED backlighting on a mech (rather than a laptop where it belongs) is a lot of bother for nothing much.

I do think though that adding RGB to the buckling spring will make difference from selling 10 of them to selling 1k+ - not because it's technically better, simply by the fact that you can't charge $400 for the keyboard which doesn't have LEDs in 2023 - and because of tooling costs it's likely can't be less than that - at least for the first batch.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Will it be an “artisinal” board made by workers paid a living wage and living in a democracy, not the Party’s chosen oligarch’s city-sized dormitory? Artisinal like manufacturing used to be until about 2000? Where the jobs were here, not over in Dystopia? That’d be different. Much more so than disappointing* backlights.

*Backlights on mechs are all disappointing. Put the very best of them beside a laptop with keyboard illumination and weep. Chiclet membrane wins that battle, hard.

Mind, having just made an unwitting argument for Made in USA Unicomp keyboards, I can’t say I find the human rights angle to be that compelling.

Mind again, my favourite boards are all 1980s US made and the present day Japan. The sweat is mine, not the sweatshop’s. I’ve never bought a Chinese made small batch board like Ellipse’s either. Costly and quite unreliable, going by the support requests spilling over here on the unofficial Model F Labs forum.

*Backlights on mechs are all disappointing. Put the very best of them beside a laptop with keyboard illumination and weep. Chiclet membrane wins that battle, hard.

Mind, having just made an unwitting argument for Made in USA Unicomp keyboards, I can’t say I find the human rights angle to be that compelling.

Mind again, my favourite boards are all 1980s US made and the present day Japan. The sweat is mine, not the sweatshop’s. I’ve never bought a Chinese made small batch board like Ellipse’s either. Costly and quite unreliable, going by the support requests spilling over here on the unofficial Model F Labs forum.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

I can try to research onshore manufacturing - but I don't think it's a practical option (plus I don't know anything about onshore manufacturers). The FSSK attempt - $100 for just the plate and foam - puts final costs somewhere way north of $600. Truth is - US manufacturers are simply too greedy.Muirium wrote: 06 Jul 2023, 23:27 Will it be an “artisinal” board made by workers paid a living wage and living in a democracy, not the Party’s chosen oligarch’s city-sized dormitory? Artisinal like manufacturing used to be until about 2000? Where the jobs were here, not over in Dystopia? That’d be different. Much more so than disappointing* backlights.

And yeah, "completely made in USA" won't give a single additional customer. People can tell whatever - but when presented with non-publicly-visible choice of paying $400 vs $600, they'll all choose $400. Been there.

I'm not sure what's so "disappointing" about those - or, rather, how that backlight is different from laptop backlight, except probably laptop being a lot flatter.Muirium wrote: 06 Jul 2023, 23:27 *Backlights on mechs are all disappointing. Put the very best of them beside a laptop with keyboard illumination and weep. Chiclet membrane wins that battle, hard.

I hope it will be larger-than-small batch - like input club or keyboardio. And for that it should be significantly modern. And that means backlight. And wireless.Muirium wrote: 06 Jul 2023, 23:27 Mind, having just made an unwitting argument for Made in USA Unicomp keyboards, I can’t say I find the human rights angle to be that compelling.

Mind again, my favourite boards are all 1980s US made and the present day Japan. The sweat is mine, not the sweatshop’s. I’ve never bought a Chinese made small batch board like Ellipse’s either. Costly and quite unreliable, going by the support requests spilling over here on the unofficial Model F Labs forum.

"small batch keyboards" are unreliable because they are designed by clowns who don't understand _anything_ about manufacturing or reliability. I've seen insides of one of the Ellipse's keyboards - and I'm shocked how badly things that aren't visible from the outside are made. From fingerprints _under_ the chromate to abrasive marks on the plate backside to the horrible bend radius of the captive USB cable to barrel surface finish - it all reeks of incompetence and carelesness. IF I ever get to actual production run (and this is quite a big IF at this point) - I would not accept such a shoddy worksmanship.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Come on, is any of this truly practical? You think your Chinese contractor wouldn’t pull tricks like that on you, too?

I’ve heard people sing Ellipse’s praises for just how much hands-on silly buggers he’s been through with the Chinese factory on his project. That praise is from the same people who slam his customer support and QA as wholly inadequate! Even I’m not odd enough to deep dive his post history and news stories about a product I’ve never wanted to buy, and that’s saying something! (I’ve already got my OG Kish, and have done since before he started his clone project.) But word is he’s been through hell and back with his factory in China, who cut corners like their margin depended on it. Because it does! That’s what makes western manufacture seem so “greedy”: they quote a price high enough to manufacture within your spec, instead of expecting to con you in every way they can.

So, how much more hell do you think you’d need?

I’ve heard people sing Ellipse’s praises for just how much hands-on silly buggers he’s been through with the Chinese factory on his project. That praise is from the same people who slam his customer support and QA as wholly inadequate! Even I’m not odd enough to deep dive his post history and news stories about a product I’ve never wanted to buy, and that’s saying something! (I’ve already got my OG Kish, and have done since before he started his clone project.) But word is he’s been through hell and back with his factory in China, who cut corners like their margin depended on it. Because it does! That’s what makes western manufacture seem so “greedy”: they quote a price high enough to manufacture within your spec, instead of expecting to con you in every way they can.

So, how much more hell do you think you’d need?

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Looks like I found the way to make flat BLE keyboard with metal case: LABELS to the rescue. LED labels on top side, model ID label on the bottom (may actually be larger - but the hole will be the same).

In theory this should work - near field is metal-free. Yes, there will be shadows caused by the metal - but I guess signal will be good enough for 1 meter range, and should anybody try to control TV with it, front lobe should be wide enough to do it.

In theory this should work - near field is metal-free. Yes, there will be shadows caused by the metal - but I guess signal will be good enough for 1 meter range, and should anybody try to control TV with it, front lobe should be wide enough to do it.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

No - because I won't design an USB port directly facing the enclosure wall. Or a solenoid connector that fries the daughterboard if you plug it wrong (this, in particular, is VERY easy to fix!). And, in general, I'll design for manufacturability - so all the corners will be cut in the spec already.Muirium wrote: 07 Jul 2023, 23:20 Come on, is any of this truly practical? You think your Chinese contractor wouldn’t pull tricks like that on you, too?

With all due respect, those people are talking out of their asses. And don't even get me started on that PCB-bending machine. The PCB was almost flat a week after being pulled from the case and left alone - so that machine is _completely_ useless (but pretty expensive, I guess). Sure, you can get as hands-on as you want, but if you don't have a slightest clue what you're doing, that won't help. It actually may even hurt - like attempts to have chunky paint (against manufacturers' production engineers' advice, I'm pretty sure). I'm eagerly awaiting reports of those chunks peeling off - because that's what happens with needlessly thick coatings.Muirium wrote: 07 Jul 2023, 23:20 I’ve heard people sing Ellipse’s praises for just how much hands-on silly buggers he’s been through with the Chinese factory on his project.

Support? He has support? Seriously? That's not support, that's mockery. I wonder if he has any warranty..Muirium wrote: 07 Jul 2023, 23:20 That praise is from the same people who slam his customer support and QA as wholly inadequate!

And this shows - on the outside of the device only.Muirium wrote: 07 Jul 2023, 23:20But word is he’s been through hell and back with his factory in China, who cut corners like their margin depended on it. Because it does!

Keycaps outer envelope, for example, is decent. Internals - not so much: you need to hold the keyboard vertically on the back to put on the keycaps, or 80% of them won't click. I even know what's wrong there - the small, seemingly pointless nub inside the keycap.

Barrels are way less refined - keys are way harder to pull out, for example.

Top plate is decent-ish, bottom plate horrible.

So, things that aren't immediately visible clearly show signs of neglect (except flipper) - and will bite users' ass pretty soon, just wait five years.

I had to work with one local custom case manufacturer recently. They make a 3D model for you to review - and they so don't give a fuck about your specs I have trouble describing the magnitude. We had FIVE rounds of changes - each round I sent them drawings of how I want it to be, and they returned something else, paying little attention to understanding my requests (and drawings!)Muirium wrote: 07 Jul 2023, 23:20That’s what makes western manufacture seem so “greedy”: they quote a price high enough to manufacture within your spec, instead of expecting to con you in every way they can.

I know manufacturing isn't a walk in the park. But I have no illusions about US manufacturing: they care about your order exactly same amount as Chinese manufacturers: ZERO. But there's spec and there's quality control. Quality is a function of process, not people

Attempts to cut corners ultimately just cost the manufacturer more - because final product won't pass QA and must be reworked. Case in point - Ellipse's IBM keys. They are better than Unicomp ones - the user-facing surface, at least. And if he cared to understand what's that small nub inside the stem is doing - they would be better all around. But it doesn't look like he cared - and now happy customers are forced to hoist their keyboards to put their beautiful keys in

- thefarside

- Location: United States

- Main keyboard: IBM 4704 F107

- Main mouse: Old, boring Logitech

- Favorite switch: Buckling spring

I didn’t know ellipse bends his PCBs. Did IBM curve theirs? I assumed it was created flat and curved in the assembly.DMA wrote: 08 Jul 2023, 01:08And don't even get me started on that PCB-bending machine. The PCB was almost flat a week after being pulled from the case and left alone - so that machine is _completely_ useless (but pretty expensive, I guess).Muirium wrote: 07 Jul 2023, 23:20 I’ve heard people sing Ellipse’s praises for just how much hands-on silly buggers he’s been through with the Chinese factory on his project.

I had a couple warranty issues and ellipse helped me. Some of my keys had defects and he mailed me replacements.

I agree. My first F77 had great paint but my second has a thicker coat with a big dried drip on a corner that sticks out. Clearly a quality difference.

I thought all Model Fs were like that? I could’ve sworn my F AT and F107 needed to be vertical too, but I could be wrong… My understanding was the flipper rests in the down position so the keyboard needed to be vertical on its back to move the spring towards the back of the barrel.DMA wrote: 08 Jul 2023, 01:08 you need to hold the keyboard vertically on the back to put on the keycaps, or 80% of them won't click. I even know what's wrong there - the small, seemingly pointless nub inside the keycap.

Regarding manufacturing, I got an email from ACS Materials about a new metal 3D printing service and wanted to share. They have some interesting examples and I wonder if Model F parts would be possible. I have no idea about the quality, specs or pricing but it sounds interesting:

https://www.acsmaterial.com/metal-3d-pr ... rvice.html

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Of course not. Why would they? in assembly PCB is held roughly curved by two rivets along the centerline, after assembly - by foam pressing via the barrels.

Good to know. But this kinda means that his promise to personally test every keyboard was a lie - how can you not notice defective keys if you test things yourself?thefarside wrote: 08 Jul 2023, 06:32 I had a couple warranty issues and ellipse helped me. Some of my keys had defects and he mailed me replacements.

This is what happens when you demand shitty paint instead of state of the artthefarside wrote: 08 Jul 2023, 06:32 My first F77 had great paint but my second has a thicker coat with a big dried drip on a corner that sticks out. Clearly a quality difference.

Nope. Or I was extremely lucky - but both my XT and F122 didn't have this problem. XTant was my daily driver, so I only torn it down couple times, but F122 was the CommonSense testbed, and I disassembled it dozens of times, and it never occured to me I need to put it vertically.thefarside wrote: 08 Jul 2023, 06:32I thought all Model Fs were like that? I could’ve sworn my F AT and F107 needed to be vertical too, but I could be wrong… My understanding was the flipper rests in the down position so the keyboard needed to be vertical on its back to move the spring towards the back of the barrel.DMA wrote: 08 Jul 2023, 01:08 you need to hold the keyboard vertically on the back to put on the keycaps, or 80% of them won't click. I even know what's wrong there - the small, seemingly pointless nub inside the keycap.

Yes, flipper rests in down position, but the key on the way down picks the spring up (that's what this diagonal slide is for! and if your keys aren't made by Unicomp, that small nub at the bottom nudges the spring into correct position. If you delete that nub (or copy it shoddily), top of the spring will end up horizontal instead of sloped towards back of the keyboard, and will not click. If you find a way to bring flipper down manually, the key will start working (because bending the spring will put it into correct position). I guess couple pictures are needed to really explain what happens there, but I'm too sleepy ATM. May be tomorrow.

metal barrel would be a disaster. Metal flipper probably too - like, really loud and scratching the PCB. Probably very expensive toothefarside wrote: 08 Jul 2023, 06:32 Regarding manufacturing, I got an email from ACS Materials about a new metal 3D printing service and wanted to share. They have some interesting examples and I wonder if Model F parts would be possible. I have no idea about the quality, specs or pricing but it sounds interesting:

https://www.acsmaterial.com/metal-3d-pr ... rvice.html

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

DMA's right. I've had a good few Model Fs—several XT's (one which became his XTant), AT and of course my beloved Kishsaver—I’m fussy enough to pull and clean the caps as I was the wash the boards before using them, and I've played with different layouts on AT and Kish, too. So several hundred cap insertions for me: all of them horizontally. Only one flipper on the Kishsaver regularly gives me trouble and needs done a second time to click. That flipper needs replaced, to be honest, but as I have it on \ I hardly use it and keep putting it off.DMA wrote: 08 Jul 2023, 07:07Nope. Or I was extremely lucky - but both my XT and F122 didn't have this problem.thefarside wrote: 08 Jul 2023, 06:32 I thought all Model Fs were like that? I could’ve sworn my F AT and F107 needed to be vertical too, but I could be wrong… My understanding was the flipper rests in the down position so the keyboard needed to be vertical on its back to move the spring towards the back of the barrel.

Helps when you're using IBM original caps, too. I try to keep Unicomp out of the mix as best I can—on looks grounds—and Ellipse's prices / wait times put me off his juicy looking replacements. The devil on my shoulder thanks you for this info re: the shoddy inside of those caps. A good reason to put off a costly, needless purchase.

- thefarside

- Location: United States

- Main keyboard: IBM 4704 F107

- Main mouse: Old, boring Logitech

- Favorite switch: Buckling spring

My first Model F was an F77 so I probably assumed all needed to be vertical. Good to know! I need to change the caps in my F107 so I’ll keep it flatMuirium wrote: 08 Jul 2023, 11:29 So several hundred cap insertions for me: all of them horizontally.

Regarding layouts, I like the TKL design you have and was curious if you had plans for a numpad, macro pad or 100% design. I also like the idea of an expanded nav cluster

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Expansions are trivial. TKL is a smallest viable form factor - something I myself would use. Not sure what "expanded nav cluster" may mean, but if you mean what F77 has - then no. Arrows and six keys above them must be separated from the rest of the keys, otherwise my fingers can't find them. It may seem that it's not a big difference from standard TKL layout - but it is. Additional physical keys can be added to the left of key field (XT F-keys style), or numpad can be reprogrammed (although right hand is a bit overloaded already - we already have nav keys, enter and backspace there exclusively after all). Additional keys create an additional problem though: custom keycaps. I kinda like current ability to just use whatever keycaps you have lying around: TKL is a base set, after all.thefarside wrote: 08 Jul 2023, 15:37 Regarding layouts, I like the TKL design you have and was curious if you had plans for a numpad, macro pad or 100% design. I also like the idea of an expanded nav cluster

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Exterior matters, don't get me wrong. Even you admitted you keep your unicomp keys separatelyMuirium wrote: 08 Jul 2023, 16:51 Ellipse doesn’t make Model Fs. IBM did.

If but he tried harder, where it counts: on the inside…

Also, not everything inside matters - but one needs to know what matters and what doesn't, and that comes from understanding what's going on inside. Like this widespread rumor that spring end must be in "12 to 1 o'clock position" - which might be true, but why exactly it needs to be that way? This is a costly requirement at assembly time - either requiring some complex jig to hold the spring in exact position, or demanding constant attention from operator and the QA person. Again, might be unavoidable - but there must be a good reason to do this, not just an anecdote and/or "we did it this way back then".

PS: all your XTs are with you - I've only got the XTant kit from you back then: plate, PCB, foam piece, fasteners and cork feet. I've got that XT off Ebay

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Yeah, this “you’re spring must be rotated wrong, bro” thing is complete shite. If I had to check spring coil alignment when seating caps on my IBMs, I’d go mental! It would be top of my complaints about Model F, because it would be ludicrous.

Spoiler: it’s not. The caps go on right far more often than not. And no surprise it’s my Unicomp caps that play silly buggers.

Ellipse’s keyboards aren’t Model Fs. They’re evidently very flaky—just today’s example from an epic thread* of so many—and would be a product recall fiasco if shipped by a real manufacturer. I appreciate that’s not what they are: they’re a hobby project scaled up, in truth. But their reputation seems to be smearing authentic Model F’s good name now, which is unfair and sad.

I don’t have an XT any more. Well, I have a few bits still left from the parts one. Sold the others long ago. XT layout ruins them for me. They’re IBM’s spare parts mule!

*As a DT mod I’m merging all the new threads I spot his buyers posting just to ask for support on these keyboards back into that main one. So I’m very aware indeed of the volume of problem reports his users write, as they insist on doing so here.

Spoiler: it’s not. The caps go on right far more often than not. And no surprise it’s my Unicomp caps that play silly buggers.

Ellipse’s keyboards aren’t Model Fs. They’re evidently very flaky—just today’s example from an epic thread* of so many—and would be a product recall fiasco if shipped by a real manufacturer. I appreciate that’s not what they are: they’re a hobby project scaled up, in truth. But their reputation seems to be smearing authentic Model F’s good name now, which is unfair and sad.

I don’t have an XT any more. Well, I have a few bits still left from the parts one. Sold the others long ago. XT layout ruins them for me. They’re IBM’s spare parts mule!

*As a DT mod I’m merging all the new threads I spot his buyers posting just to ask for support on these keyboards back into that main one. So I’m very aware indeed of the volume of problem reports his users write, as they insist on doing so here.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Might actually be legit - I tried rotating the spring and it's kinda getting worse, plus original springs all seem to be in that position (but now that I have 400 examples I actually need to recheck.) The main question is - _why_ does it matter? If the answer is known - it can be designed away, or it might be that existing solution is the easiest way to fix the problem - but it will be known, not mythical.Muirium wrote: 09 Jul 2023, 12:21 Yeah, this “you’re spring must be rotated wrong, bro” thing is complete shite.

Ah, so that's why his users are so organized and don't flood this forum with hundreds of topics about the same thing!Muirium wrote: 09 Jul 2023, 12:21 *As a DT mod I’m merging all the new threads I spot his buyers posting just to ask for support on these keyboards back into that main one. So I’m very aware indeed of the volume of problem reports his users write, as they insist on doing so here.